Chapter 3 Cutting Function

20

3.6 Back to Reference Function

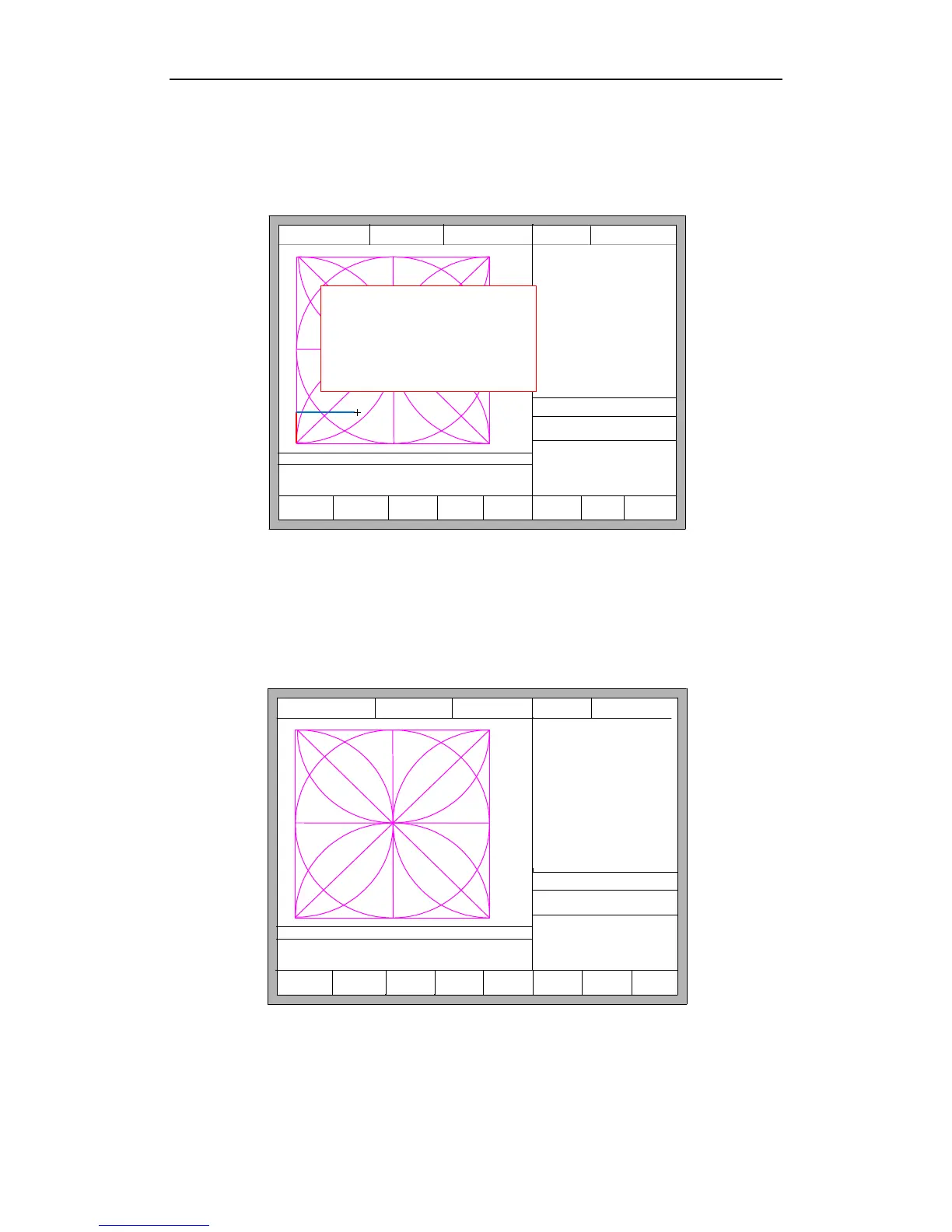

Pause in the processing, if press the 【F3】, then the system will prompt:

F1 Back F2 Demo F3 GoBack

F4

Speeddown

F5

Speedup

F6

Preheatdown

F7

Preheatup

F8

JumptoPierce

FLSK F2200T

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Stop

Current Line/Hole:

00000/00000

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

1:(TEST PATTERN)

2:G92

X:+000000.0

Y:+000000.0

Manual 【F】 keepMov

StepDis【G】 5.00 Flame Cu 【M】

CutSpeed 【X】1000.00 Kerf【N】1.20

ManualSpeed【Y】3000.00 Angle 0.00

Are you sure to return?

ENTER: sure ESC: cancel

●Ignition s

●LowHeat s

●HighPreheat s

●Pierce1 s

●Pierce2 s

●Pierce3 s

●TorchUp s

●TorchDn s

●THC En

●Blow s

Fig. 3.4 Return reference prompt

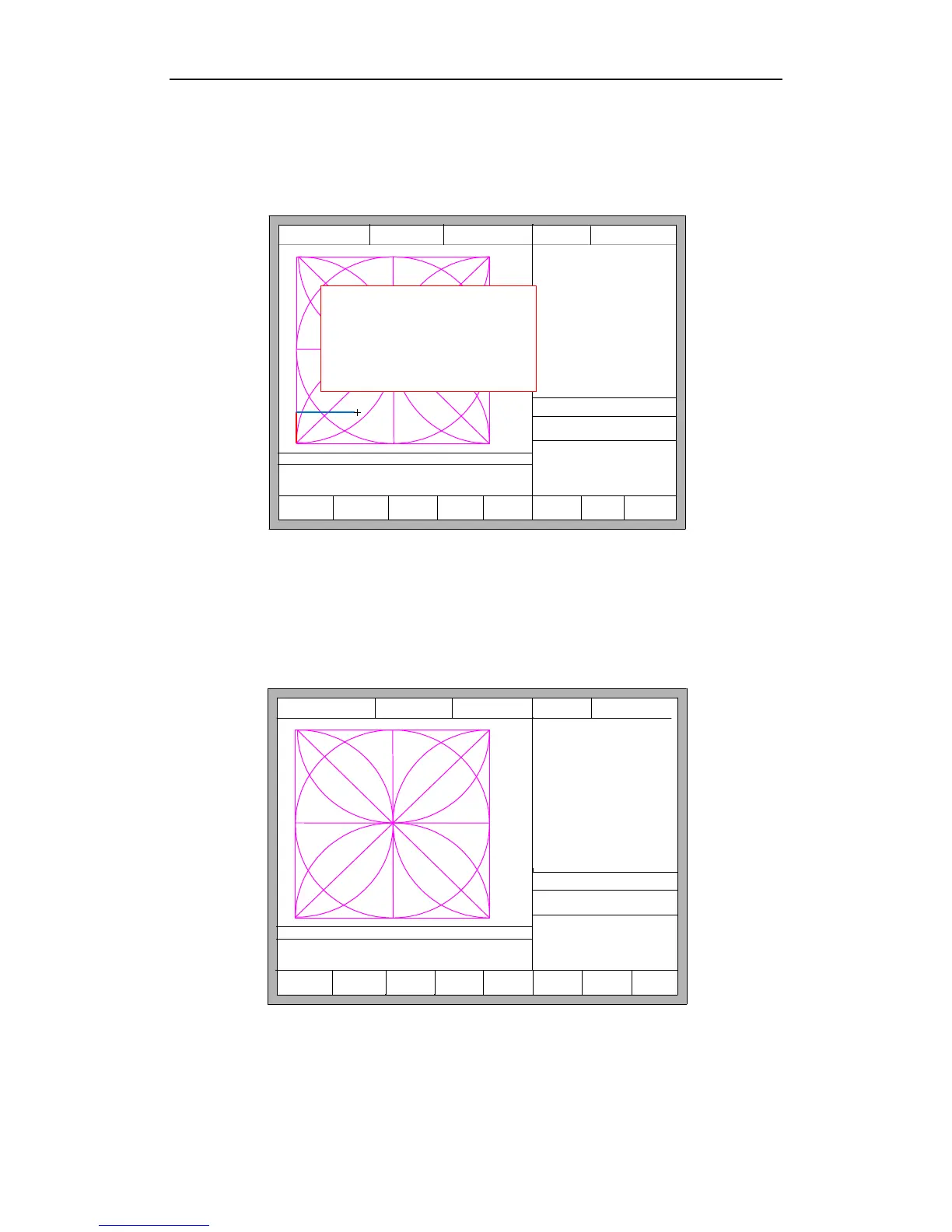

Press the Enter key, the system will automatically return to the starting point of

the work piece, and then the system automatically switches to processing the main

interface, and waits for further user action.

F1 ShapeLib F2 Files

F3

PartOption

F4 Setups F5 Diagnose F6 ZoomIn

F7

ManualMove

F8 Zero

FLSK F2200T

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Stop

Current Line/Hole:

00000/00000

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

1:(TEST PATTERN)

2:G92

X:+000000.0

Y:+000000.0

Manual 【F】 ContiMov

StepDis【G】 5.00 Flame Cu 【M】

CutSpeed 【X】1000.00 Kerf【N】1.20

ManualSpeed【Y】3000.00 Angle 0.00

●Ignition s

●LowHeat s

●HighPreheat s

●Pierce1 s

●Pierce2 s

●Pierce3 s

●TorchUp s

●TorchDn s

●THC En

●Blow s

Fig. 3.5 main process interface

During the return process, the user can press the "Stop" button to stop the

operation, and can continue to return operation after pressing of 【F3】. Number of

Loading...

Loading...