Chapter 3 Cutting Function

14

Chapter 3 Cutting Function

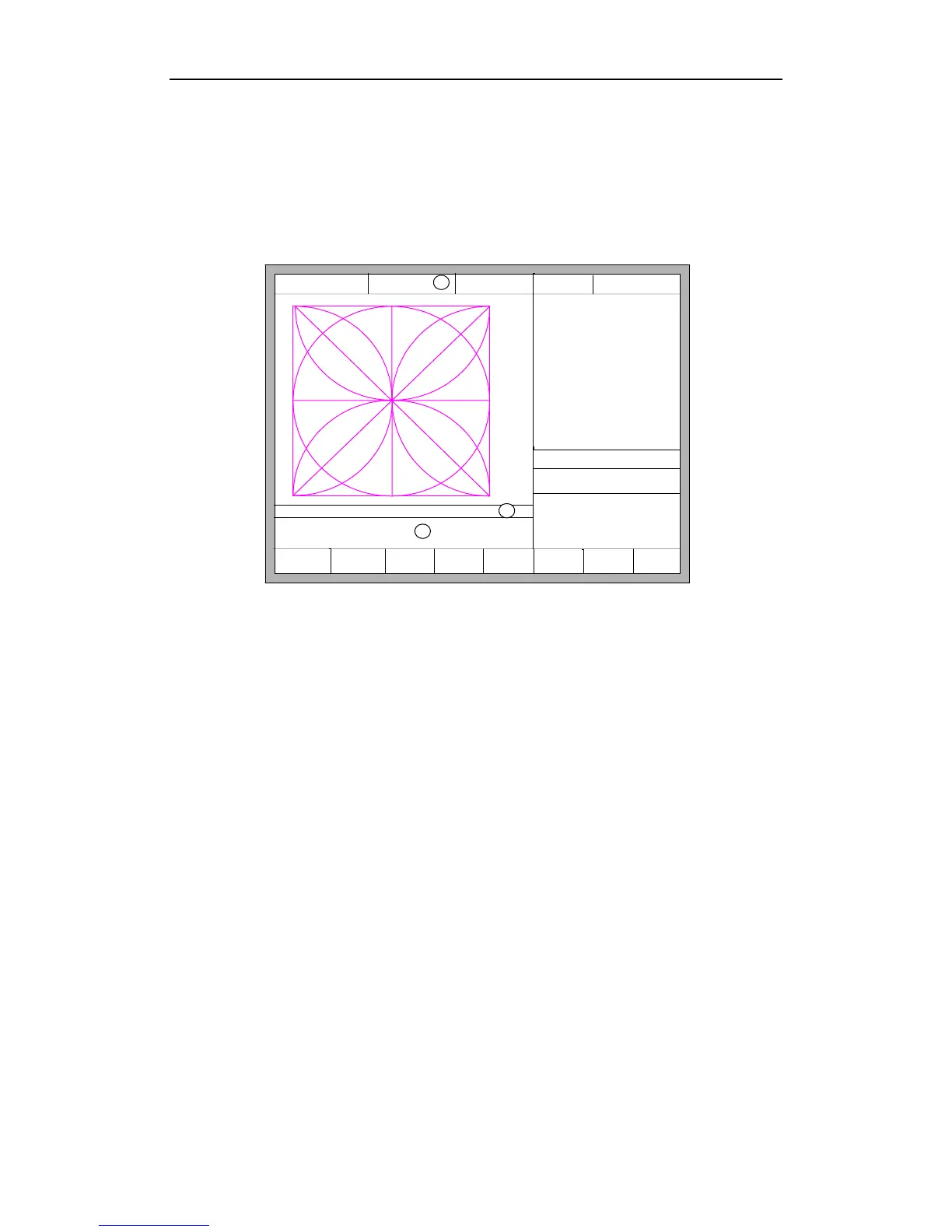

In the main interface, press the 【SPACE】to enter the cutting interface, shown as

follows:

F1 ShapeLib F2 Files

F3

PartOption

F4 Setups F5 Diagnose F6 ZoomIn

F7

ManualMove

F8 Zero

FLSK F2200T

Version 3.3.73.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Stop

Current Line/Hole:

00000/00000

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

1:(TEST PATTERN)

2:G92

X:+000000.0

Y:+000000.0

●Ignition s

●LowHeat s

●HighPreheat s

●Pierce1 s

●Pierce2 s

●Pierce3 s

●TorchUp s

●TorchDn s

●THC En

●Blow s

Manual 【F】 StepMov

StepDis【G】 5.00 Flame Cu 【M】

CutSpeed 【X】 300.00 Kerf【N】1.40

ManualSpd 【Y】3000.00 Angle 0.00

3

1

2

Fig 3.1 cutting function interface

①Shows the current workpiece's cutting path, including the slotted value.

②Shows the G-code being processed, shows the current and next line.

③Shows the current cutting speed, during processing, you can press the

keyboard's number keys 【1】 - 【9】 to achieve quick speed regulation. For example,

press the number【3】, the speed is automatically adjusted to 30%; press the number

【8】 the speed is automatically adjusted to 80%.

X shows the absolute coordinate of the torch in X direction.

Y shows the absolute coordinate of the torch in Y direction.

In the cutting interface:

Press 【X】: Modify the current cutting speed.

Press 【Y】: Modify the current speed manual shift car.

Press 【F】: Change the current manual method.

Press 【G】: Modify the current fixed-length fixed long-distance move.

【START】(【F9】): Start cutting.

【STOP】(【F10】): Parking, the system can suspend all ongoing actions.

【F1】:The torch move back along the cutting path(I / O port closed)

【F2】: The torch forward along the path (I / O port closed).

Loading...

Loading...