Chapter 3 Cutting Function

24

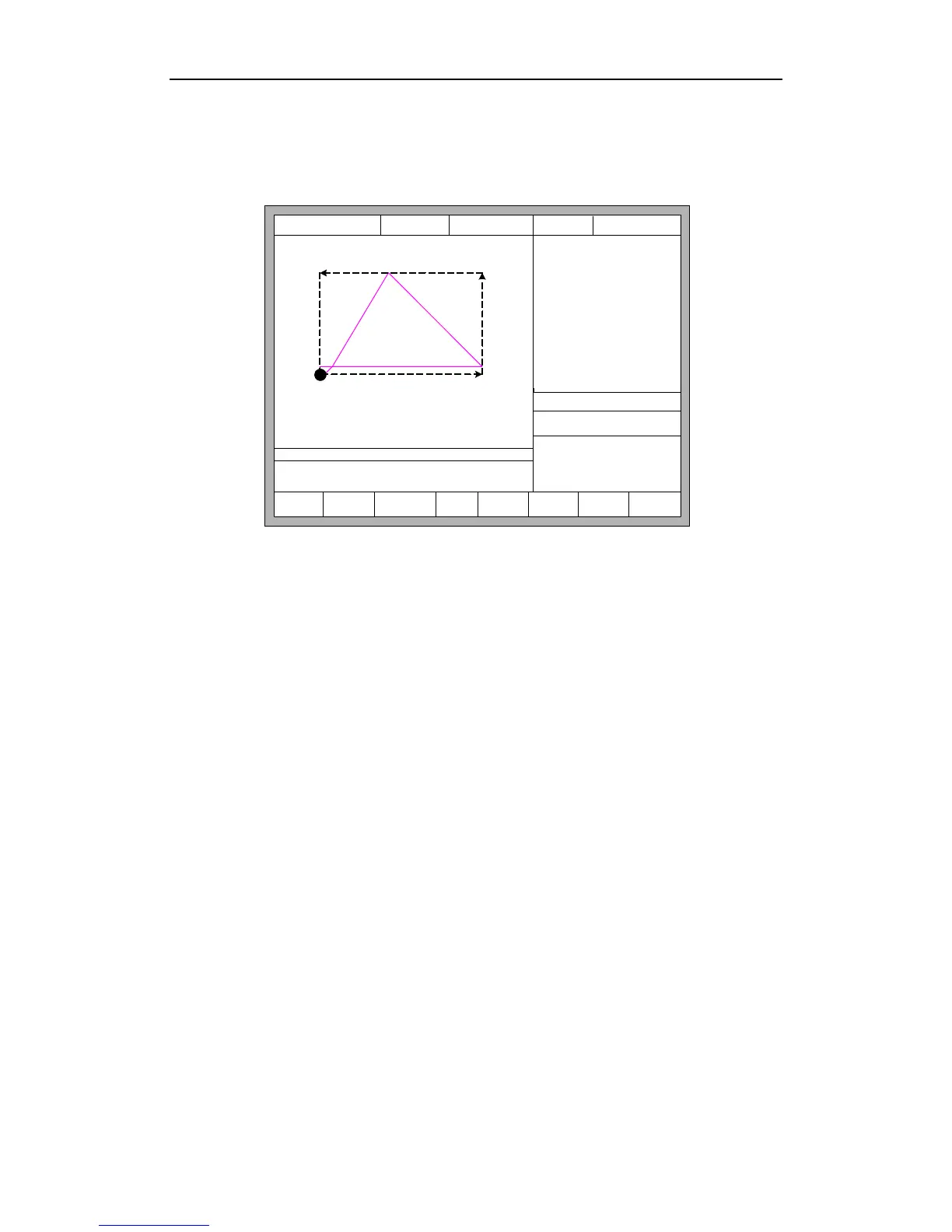

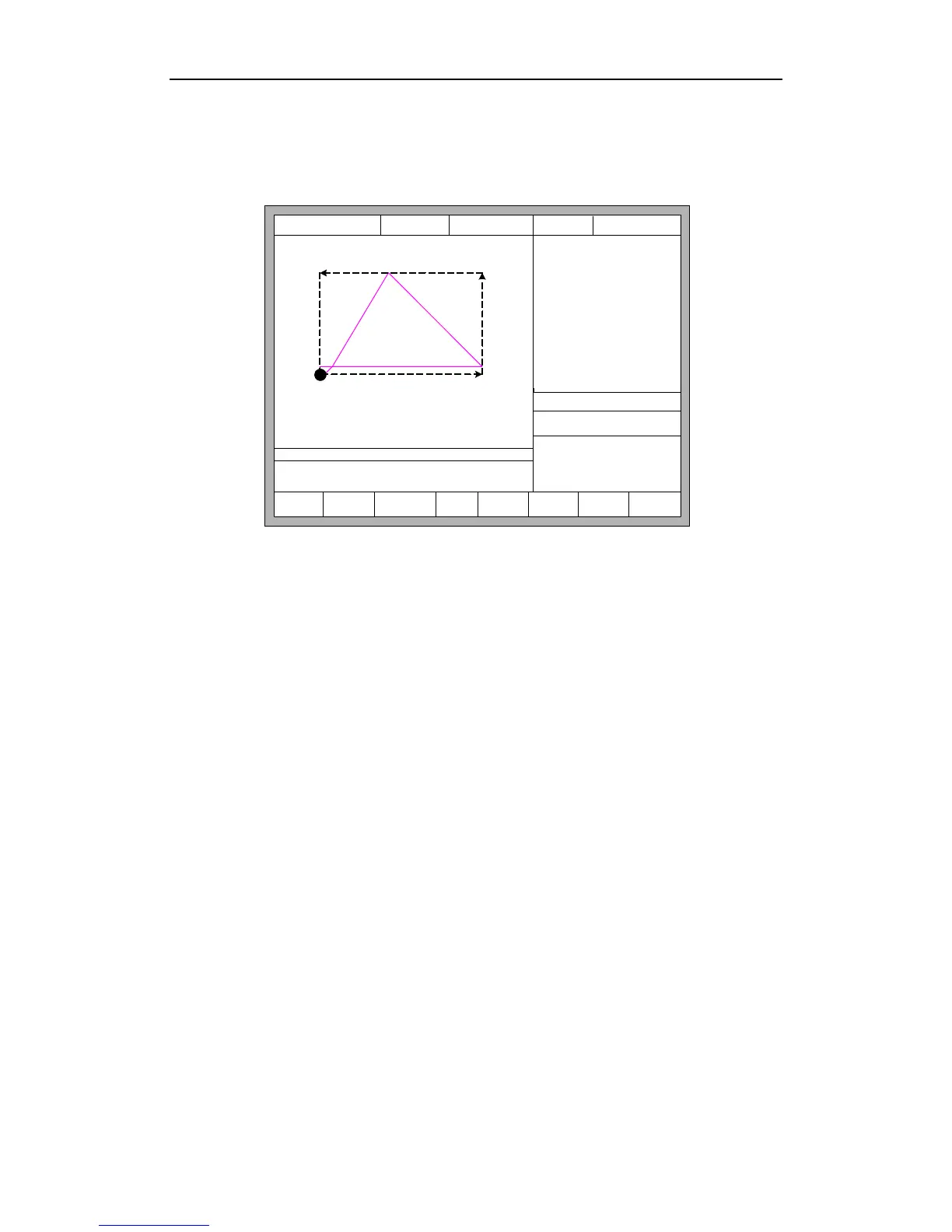

3.11 Frame

+X:500.00 -X:0.00 +Y:500.00 -Y:0.00

X:+000000.0

Y:+000000.0

1:(TEST PATTERN)

2:G92

FLSK F2200T

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Stop

Current Line/Hole:

00000/00000

CutSpeed 【X】1000.00 Kerf【N】1.20

ManualSpeed【Y】3000.00 Angle 0.00

Manual 【F】 keepMov

StepDis【G】 5.00 Flame Cu 【M】

F1 Back F2 Demo F3 Frame

F4

Speeddown

F5

Speedup

F6

PreheatDown

F7

PreheatUp

F8

JumptoPierce

●Ignition s

●LowHeat s

●HighPreheat s

●Pierce1 s

●Pierce2 s

●Pierce3 s

●TorchUp s

●TorchDn s

●THC En

●Blow s

Fig. 3.10 Walk along frame

Before the beginning of the process, if press 【Space】the system will enter into

the interface of auto processing, at this time, 【F3】is the function of walking along

frame,after press 【F3】, system will walk against the clock along the virtual frame

as the figure 3.10 shows, the beginning point is the lower left corner. In the end of the

walking, the system will prompt “Quit frame test? ENTER: Back, ESC: No Back”. At

this time, press【Enter】, the system will automatically back to the process of

beginning point of parts. If press 【ESC】, the system will stop at current point.

In the process of walking along frame, press STOP, the system

suspends

operation, and press START, the system resumes walking. Press 【F3】again, the

system returns to the starting point.

3.12 Arc THC Instruction (typical of the "T" in F2000 series

CNC system)

3.12.1 Wiring Instruction

F2100T System links with location proximity switch, arcing signal of plasma

power and arc interface of partial pressure circuit board by 7 cores socket, links with

lifting motor (limiting switch) by 5 cores socket. Pins interpretation schematic shows

Loading...

Loading...