Chapter 4 Part Option

32

【ENTER】, the system will back to the start point of the operation, if press 【ESC】, the

system will do nothing but go back to the graphic interface.

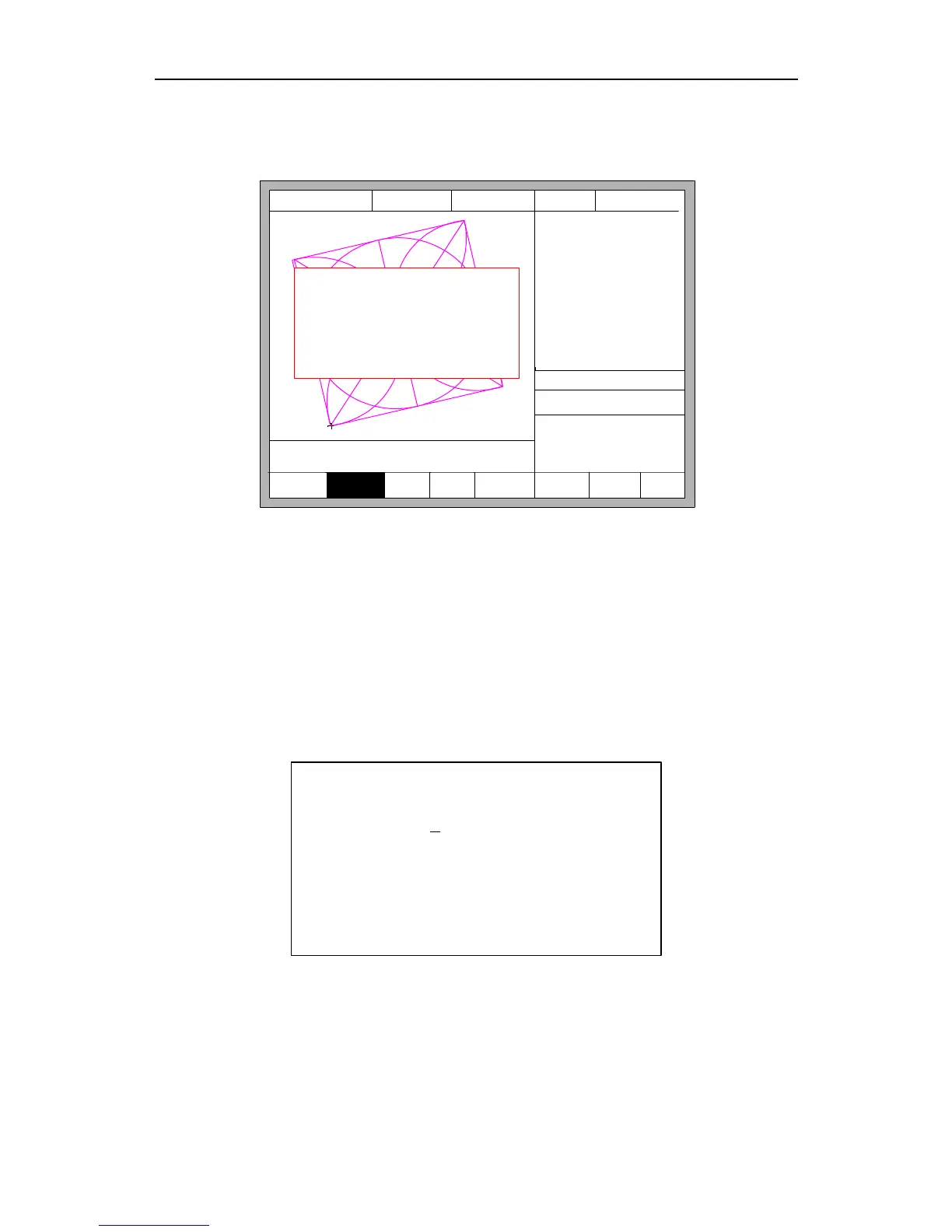

F2 Angle F3 Array F4 Scale

F5

SelLinePierce

F6 EditFile F7 Revert

FLSK F2200T

Version 3.3.71.1

Speed:

00000

File:

SHAPE_43.TXT

Status:

Pause

Current Line/Hole:

00000/00000

X:+000053.2

Y:+000009.4

【X】 Xmirror

【Y】 Ymirror

1:(TEST PATTERN)

2:G92

CutSpeed 【X】1000.00 Kerf【N】1.20

ManualSpeed【Y】3000.00 Angle 0.00

Manual 【F】 keepMov

StepDis【G】 5.00 Flame Cu 【M】

F1

StartPoint

F8 OK

Enter: Return back

ESC: Don’t move back

Angle: 10.048

Fig 4.6 Return to the start point after adjusting

4.3.2 Steel Plate Adjust Angle Memory Function

About steel plate adjust angle memory,please refer to the section of 8.7.6.6.

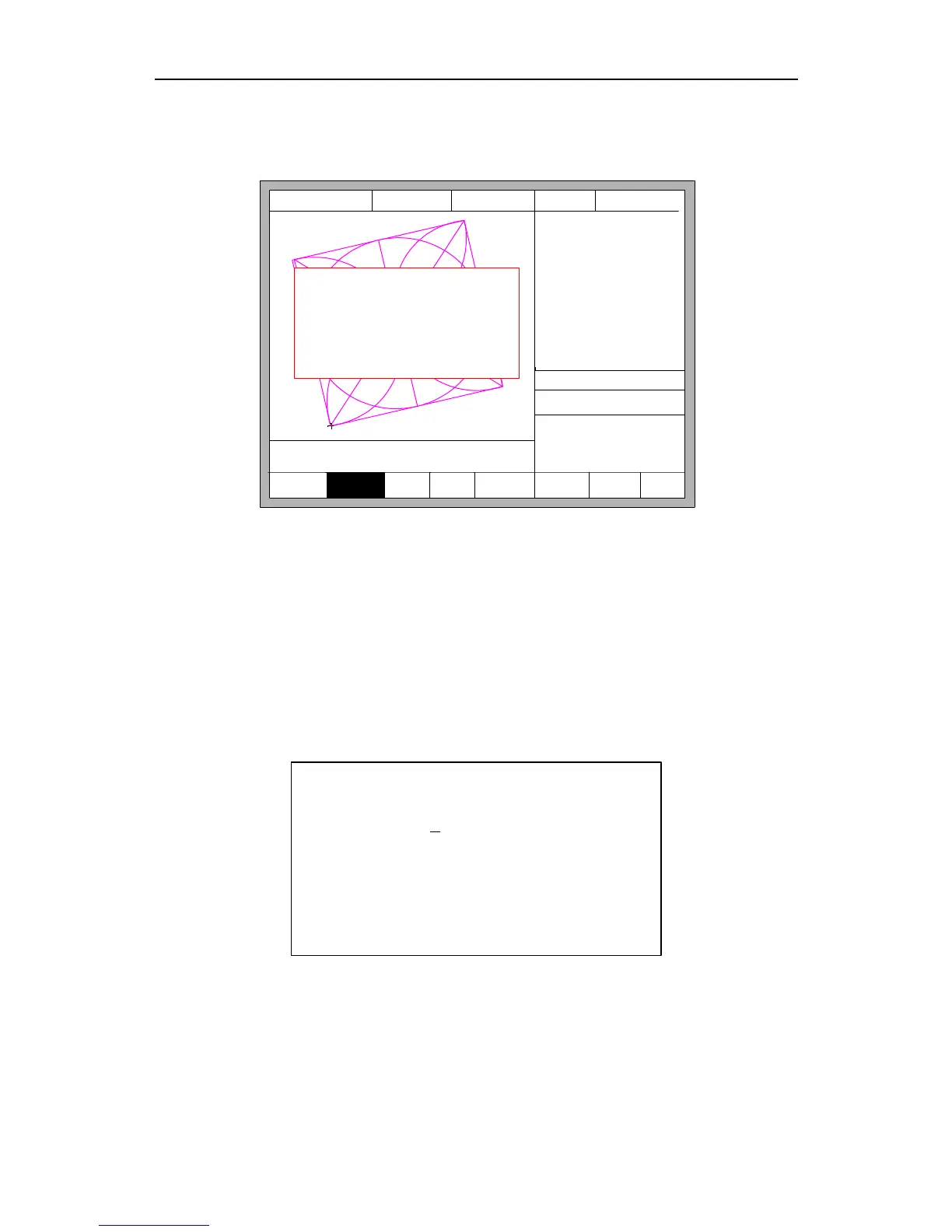

4.3.3 Enter Angle

When the angle of the current work piece is known, you can enter the angle:

Please enter angle

min:-360 max:360

Angle: 0.00

Note:

>0 Rotate CCW on the base of current

<0 Rotate CW on the base of current

=0 Reset the current part to 0 degree

Enter angle

After manually enter the angle, press 【ENTER】 to make sure, the graphic will be

rotate with the corresponding angle. Positive angle means rotate in counterclockwise,

while negative means clockwise. Press 【ESC】 to exit angle adjusting.

Illustration: when enter angle 0, process graph will restore to the location of 0°, at

Loading...

Loading...