Planning the electrical installation 61

To operate as a protective conductor, the shield conductivity requirements according to

IEC 61439-1 are shown below when the protective conductor is made of the same metal

as the phase conductors:

According to NEC (National Electrical Code, applicable in the USA), the size of the

grounding conductor must not be less than defined in this table:

Busbar dimensioning

Dimension the busbars according to the maximum output current and the instructions of

the manufacturer regarding temperature coefficients and load profiles. For more

information, contact FIMER.

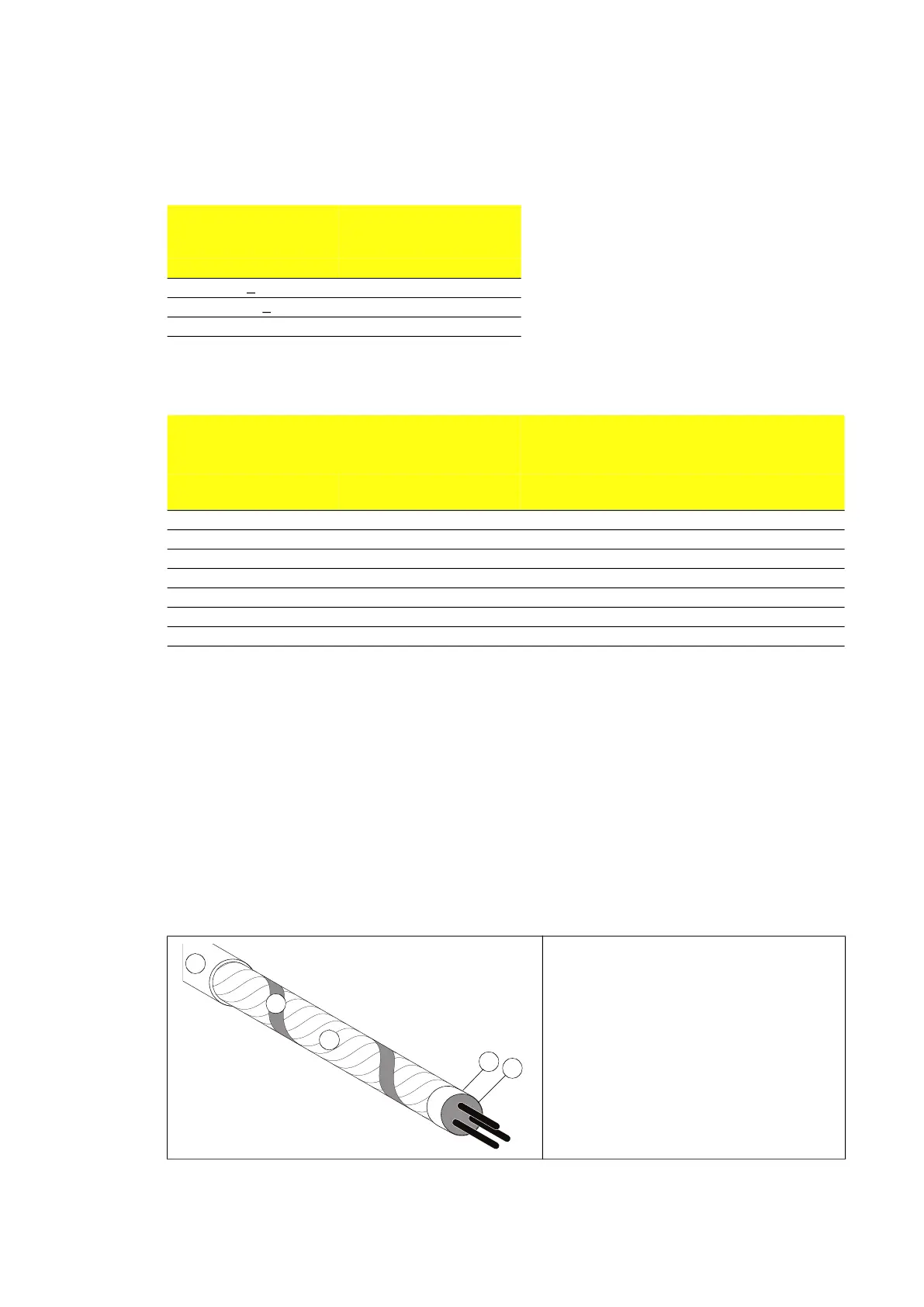

Sufficient shield conductivity to suppress emissions

To effectively suppress radiated and conducted radio-frequency emissions, the cable

shield conductivity must be at least 1/10 of the phase conductor conductivity. The

requirements are easily met with a copper or aluminum shield. The minimum requirement

of the cable shield is shown below. It consists of a concentric layer of copper wires with an

open helix of copper tape or copper wire. The better and tighter the shield, the lower the

emission level.

Cross-sectional area of

the phase conductors

Minimum cross-sectional

area of the corresponding

protective conductor

S (mm

2

) S

p

(mm

2

)

S <

16 S

16 < S <

35 16

35 < S S/2

Size of largest ungrounded service-entrance

conductor or equivalent area for parallel conductors

(AWG/kcmil)

Size of grounding electrode conductor

(AWG/kcmil)

Copper Aluminum or copper-clad

aluminum

Copper Aluminum or copper-clad

aluminum

2 or smaller 1/0 or smaller 8 6

1 or 1/0 2/0 or 3/0 6 4

2/0 or 3/0 4/0 or 250 4 2

Over 3/0 through 350 Over 250 through 500 2 1/0

Over 350 through 600 Over 500 through 900 1/0 3/0

Over 600 through 1100 Over 900 through 1750 2/0 4/0

Over 1100 Over 1750 3/0 250

1. Insulation jacket

2. Copper wire screen

3. Helix of copper tape or copper wire

4. Inner insulation

5. Cable core

1

3

2

4

5

Loading...

Loading...