Rev 4/2018

45

MACHINE BREAK-IN

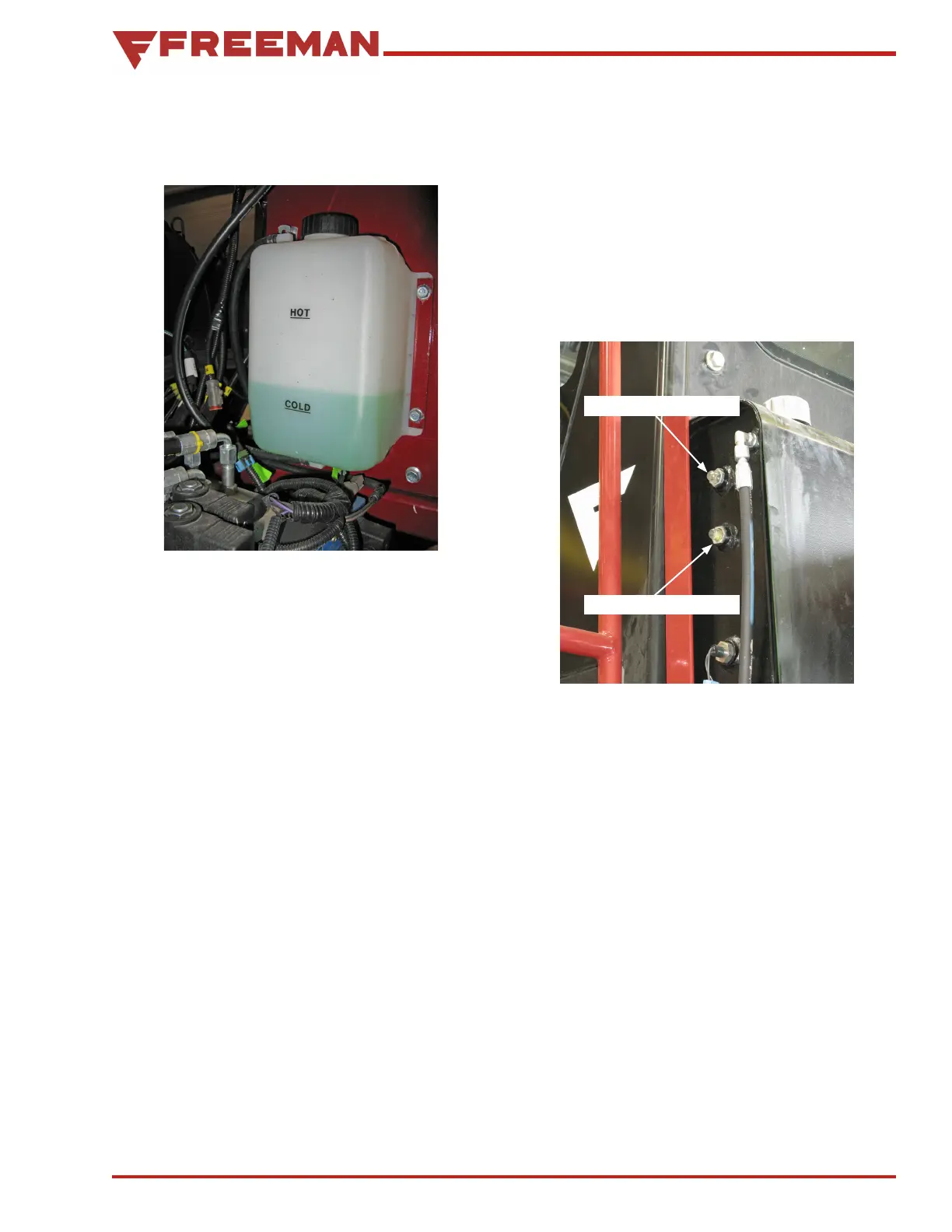

B. Coolant Overflow Tank

Figure 52. Coolant Overflow Tank

(tank may vary between models)

NOTE: Some increase in oil consumption

may be expected when low viscosity oils are

used. Check oil levels more frequently.

4. Check engine oil level (see Figure 51 on page

44) with dipstick (A) more frequently during

engine break-in period. If oil must be added during

this period, Break-In Oil part number 907811 is

preferred. (See ENGINE BREAK-IN OIL in Fuel,

Coolant, and Lubricants section of Engine Manu-

facturer's Operator's Manual.)

5. After the first 100 hours (maximum), change engine

oil and replace the oil filter. (See CHANGING OIL

FILTER in Engine Manufactures Operators Manual.)

Fill crankcase with seasonal viscosity grade oil.

(See DIESEL ENGINE OIL in Fuel, Coolant, and

Lubricants section of your Engine Manufacturer's

Operator's Manual.)

6. Check coolant level (see Figure 52) in reservoir (B).

Level must be between the HOT and COLD marks.

7. Follow fluid recommendations in Fuel, Coolant, and

Lubricants section very closely.

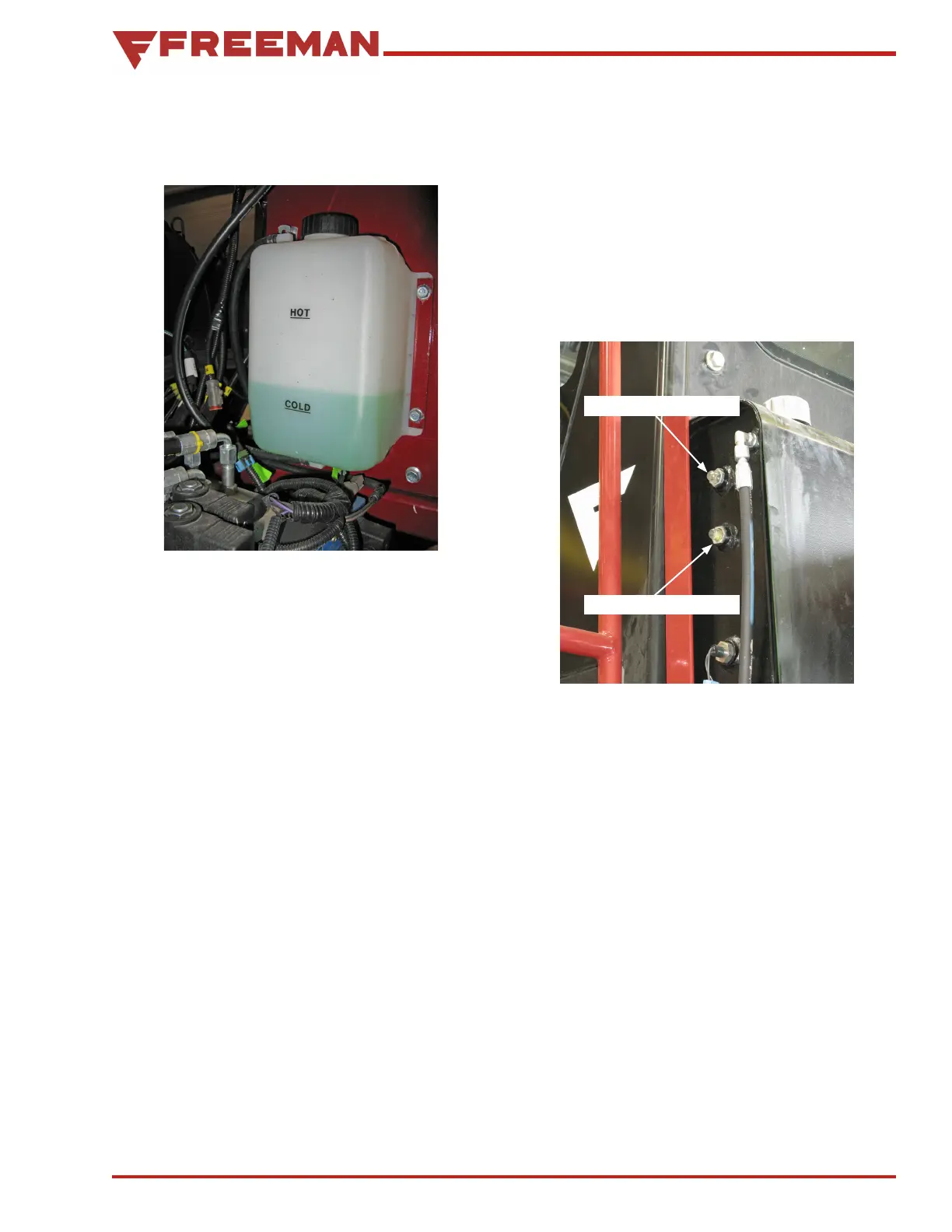

8. Check the hydraulic oil level in the tank located

behind the operator's cab (see Figure 53). The oil

level must be between the two sight gauges. Inves-

tigate cause for any loss of hydraulic fluid.

Upper Sight Gauge

Lower Sight Gauge

Figure 53. Hydraulic Oil Level

9. Follow fluid recommendations in Fuel, Coolant,

and Lubricants section very closely in your Engine

Manufacturer's Operator's Manual.

Loading...

Loading...