74

Rev 4/2018

SETTINGS AND ADJUSTMENTS

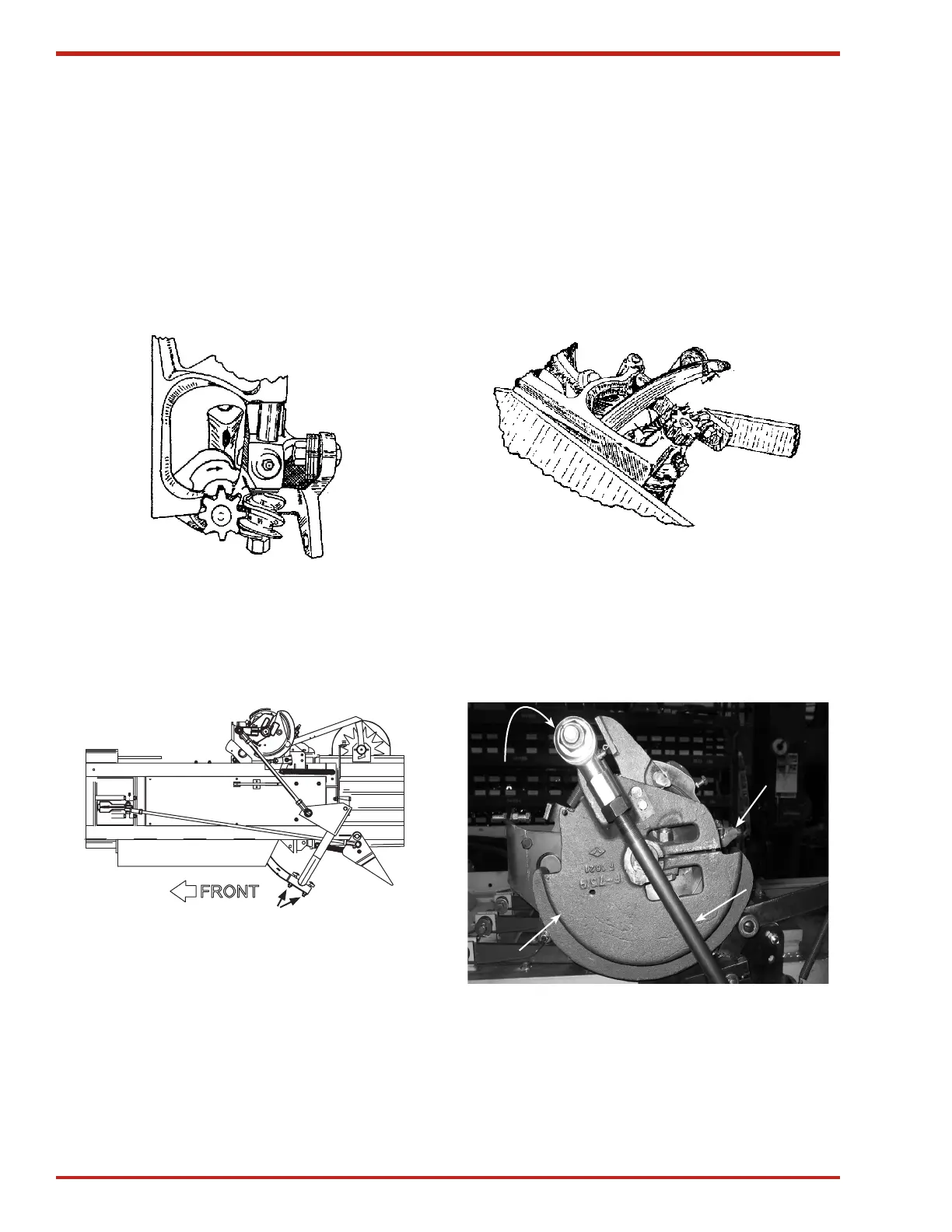

4. Adjust needle height by loosening the lock nuts on

the needle yoke drive rod (see Figure 110). Turn the

rod to the right or left for desired setting. All of the

Freeman self propelled balers have a needle yoke

drive rod on each side. Be sure both are adjusted

for equal load on each rod at top dead center.

4½

Figure 109. Needle Eye To The Twine Disc

Top Dead Center (TDC). TDC is when the needles

are at the highest point of travel. At this time the

Needle Yoke Drive Rod is in the 11 o’clock position

(see Figure 110).

Needle

Needle Yoke

Drive Rod

Clutch

11 o’clock

Position

Figure 110. Needles at TDC, left-hand view

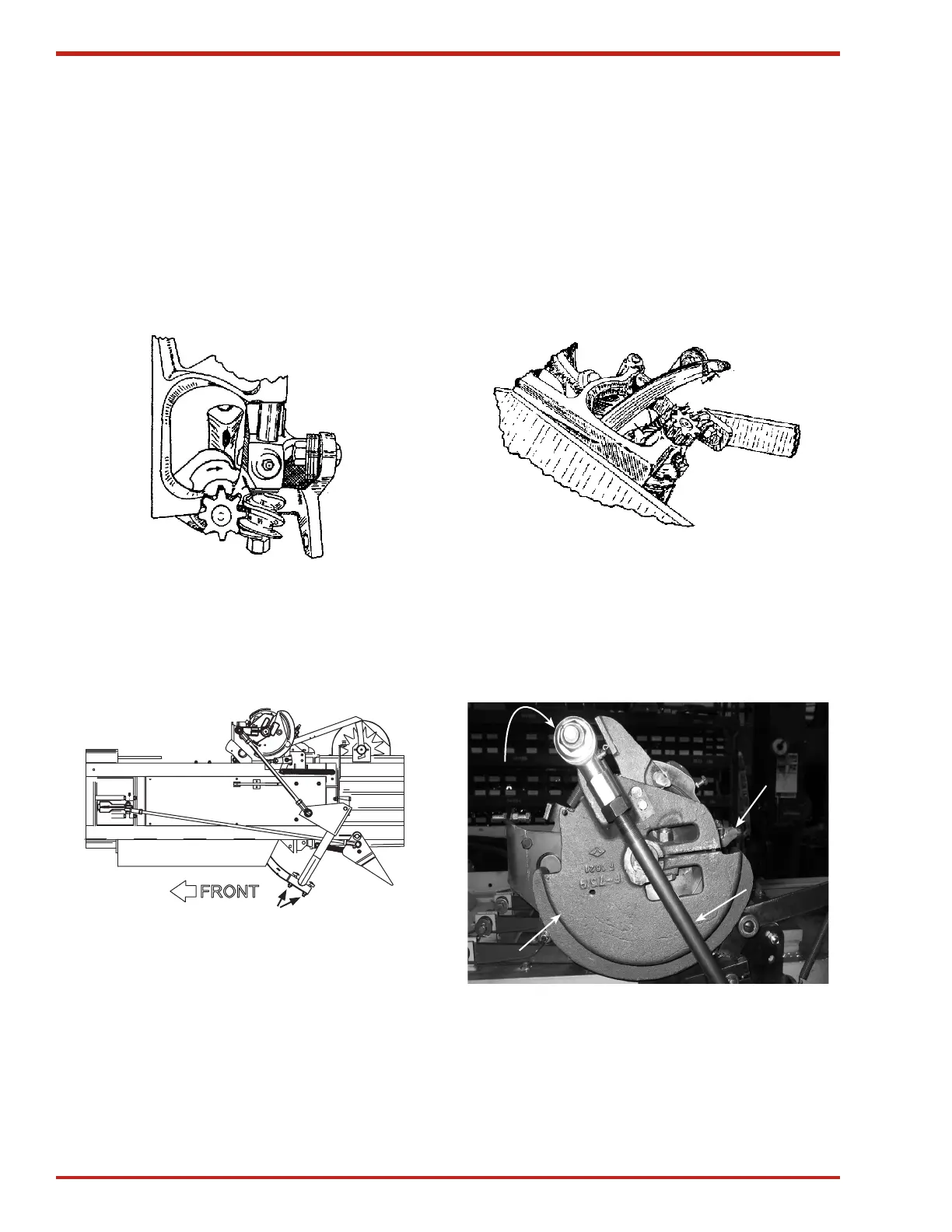

Twine Needle Adjustment

1. Trip the knotter clutch and swing the needles up

through the bale chamber by turning the flywheel

coun terclockwise by hand. The needles should

be adjusted left or right so that there is 0 to 1/32"

clearance between the nee dle and the knotter bill

hook pinion, (see Figure 107). Adjust by sliding the

needle left or right on the needle yoke.

Figure 107. Knotter

2. The needles should clear the twine disc cleaner

1/8". To increase the distance between the needle

and the twine disc cleaner, loosen the front and

tighten the rear needle anchor bolts (A), Figure 108.

To decrease the clearance re verse the procedure.

A

Figure 108. Needle Anchor Bolts

3 Trip the knotter and turn the flywheel counterclock-

wise, by hand, until the needles are in the upper-

most position. The distance from the bottom of the

needle eye to the twine disc should be 4 -1/2" (see

Figure 109).

Loading...

Loading...