Rev 4/2018

87

Twine Routing (3 tie shown)Twine Routing (3 tie shown)

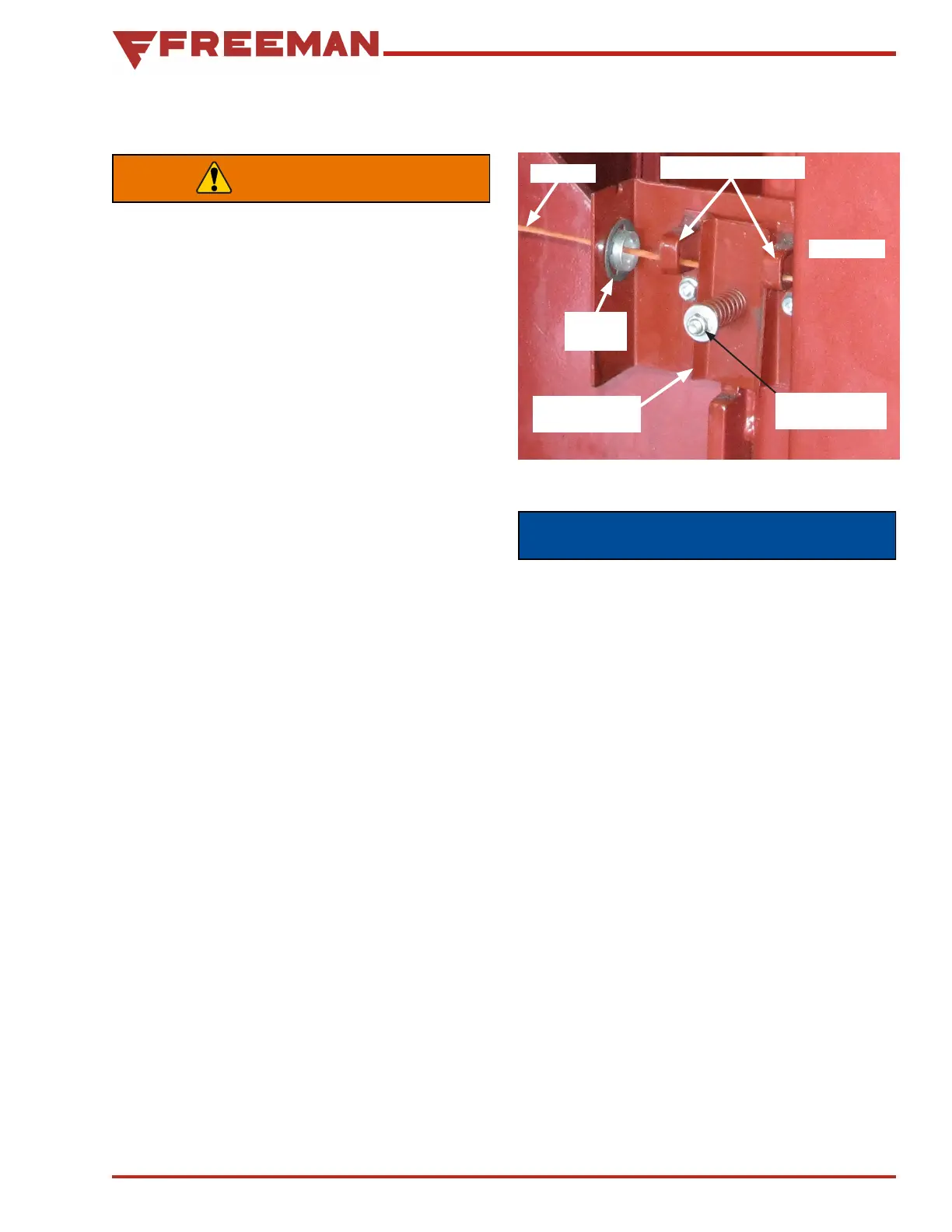

Bottom Tension

Plate

Twine Guide Loops

Twine Box

Guide

Bushing

To Baler

Tension

Adjustment Nut

Figure 139. Twine Tensioners

NOTICE

The twine tension assemblies must be

adjusted so that there is a slight amount of

drag on the twine. If the twine tensioner is

too loose, the twine lashes out and the twine

fingers are not able to grasp the twine. If the

twine tensioner is too tight, the twine may

break or come out of the twine holder.

8. It should take 3-5 lbs of force to get the

twine to move through the tensioners. Turn

each tension adjustment nut clockwise to

increase tension on the twine or counterclock-

wise to decrease the tension on the twine.

9. Twine from the top tensioner threads through

the top guide in the bracket that is mounted to

the lower right side of the bale chamber. Twine

from the middle tensioner threads through

the middle guide, and twine from the bottom

tensioner to the bottom guide (See Figure 156).

WARNING

Always shut baler off and wait for all motion

to cease before threading twine.

1. Make sure the needles are in the home position

(fully retracted).

2. Place twine in twine box. It is normal to feel

some resistance when closing the doors after

loading new twine.

NOTE: The baler's twine box is designed to

hold twine in a ball, not in a box. Boxed twine

will not fit.

3. If using multiple balls of twine per knotter, tie

the successive units of twine together (consult

your twine manufacturer for recommended

knots).

4. Feed one strand of twine out through each

of the twine guide bushings in the side of the

twine box and through the first twine guide loop

(See Figure 1399).

5. Pull down/out on the bottom plate of the

twine tensioner and place one strand of twine

between the two plates, release the bottom

tensioner plate to hold the twine in place. Feed

the twine through the second guide loop, then

out through the guide bushing in the in the

tensioner bracket. Repeat for the remaining

strands.

6. It should take 3-5 lbs of force to get the twine to

move through the tensioners. Turn each tension

adjustment nut clockwise to increase tension

on the twine or counterclockwise to decrease

the tension on the twine.

7. It should take 3-5 lbs of force to get the twine to

move through the tensioners. Turn each tension

adjustment nut clockwise to increase tension

on the twine or counterclockwise to decrease

the tension on the twine.

Loading...

Loading...