84

Rev 4/2018

5. Dispose of used oil in accordance with local

regulations.

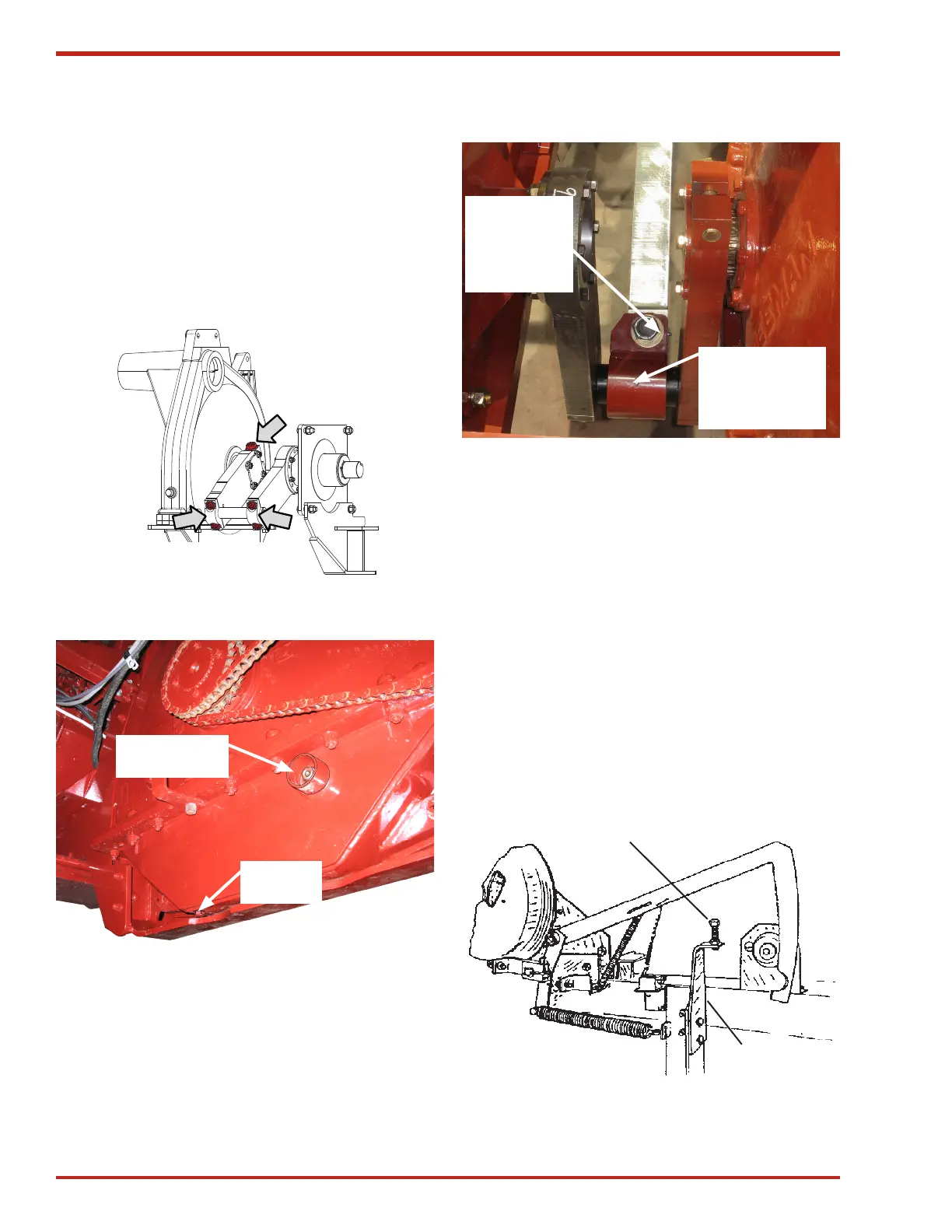

Check Bolts on Crank Arm Every 3 months/125

hours/25,000 bales, whichever comes first

(see Figure 12).

1. Torque the four (4) retaining cap bolts to

340 ft-lbs.

2. Torque the one (1) clamp bolt to 750-755 ft-lbs.

4 Retaining Cap

Bolts

340 Ft-Lbs

1 Clamp Bolt

750-755 Ft-Lbs

Figure 130. Crank Arm Torque

Fill/Check

Plug

Drain

Plug

Figure 131. Gearbox

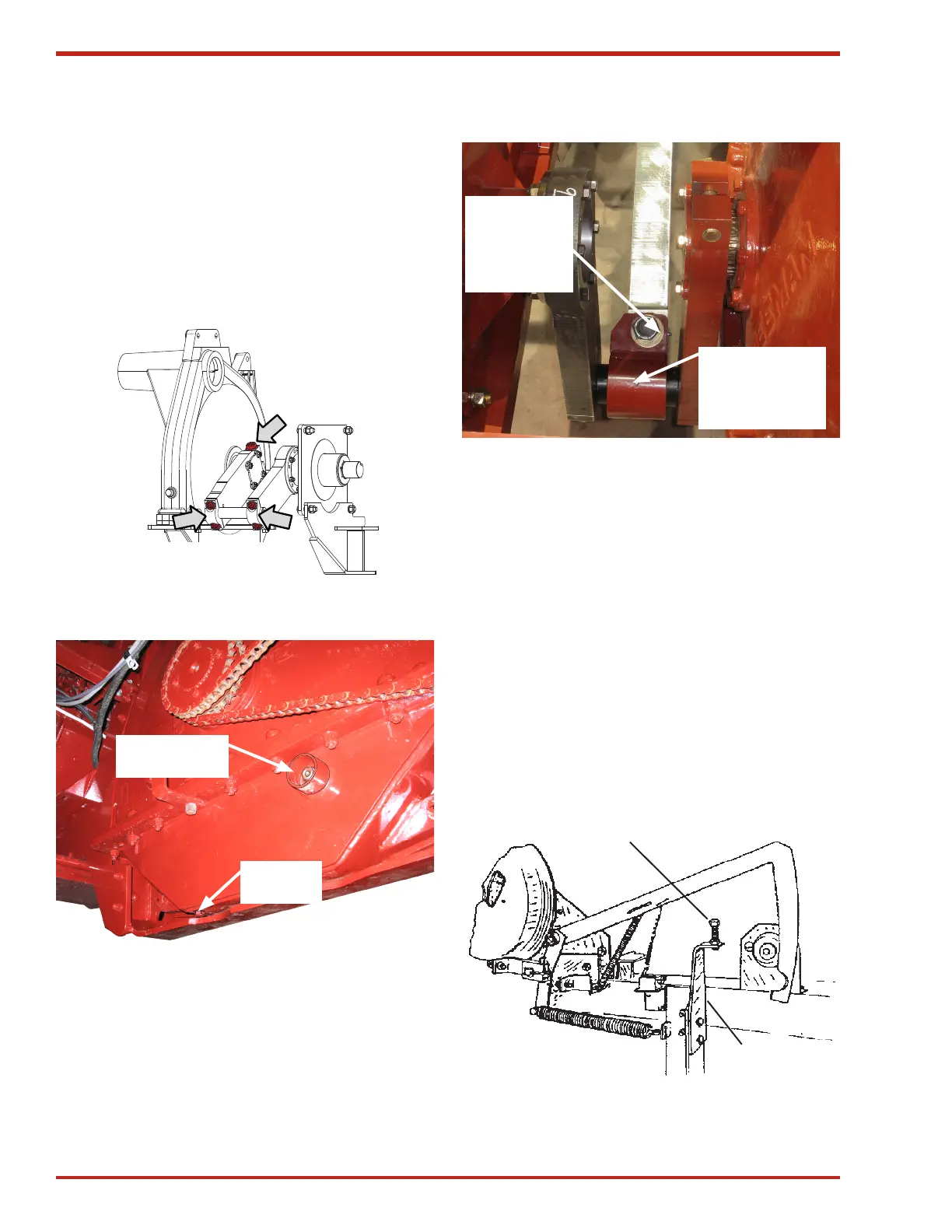

Connecting Rod/Crank Arm:

Grease the connecting rod bushing daily until you

just see grease emerging from around the bushing

(see Figure 132).

Grease the gearbox crank arm bearings at the

beginning of every season, and then every 50

hours (see Figure 132).

Figure 132. Gearbox Lubrication (Top View)

Gearbox Crank

Arm Bearing

Grease

Fitting

Connecting

Rod Bushing

Grease

Fitting

Bale Length

The operating speed of the baler has a direct effect

on the bale length. To help maintain a consistent

bale length, adhere to baler "Operating Speed" on

page 55.

Bale length is adjusted by changing the height of

the trip bar stop bolt (see Figure 133). Raising the

bolt decreases bale length and lowering the bolt

increases bale length.

If no more adjustment is available with the trip bar

stop bolt, change the height of the meter trip bar

stop. Use the holes provided to adjust the meter

trip bar stop. If the meter trip bar stop is moved,

the meter trip bar bolt will need adjustment.

Trip Bar Stop

Trip Bar Stop Bolt

Figure 133. Bale Length

Loading...

Loading...