Rev 4/2018

77

SETTINGS AND ADJUSTMENTS

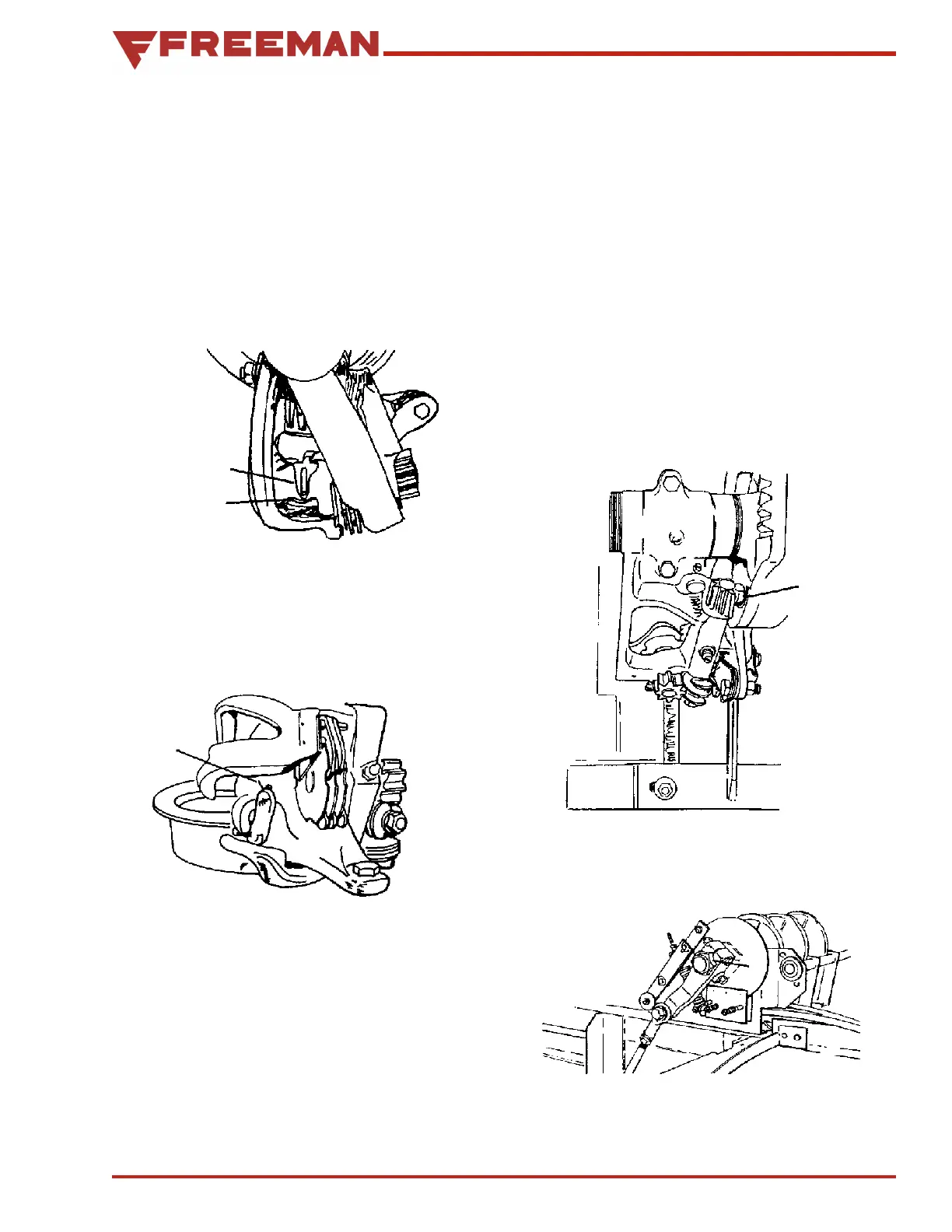

Knife Arm

The knife arm cuts the twine and strips it off of the

bill hook during the knotter's tying process.

The stripper flange on the knife arm should just

touch the bill hook with firm pressure as the stripper

flange advances the knot past the end of the bill

hook (see Figure 116).

Bill Hook

Stripper

Flange

Figure 116. Knotter

The knife arm should be 1/4" to 3/4" past the end

of the bill hook when the knife arm is in the most

extreme position (see Figure 117). Correct the

adjustment of the knife arm by replac ing it.

1/4"- 3/8"

Figure 117. Knotter

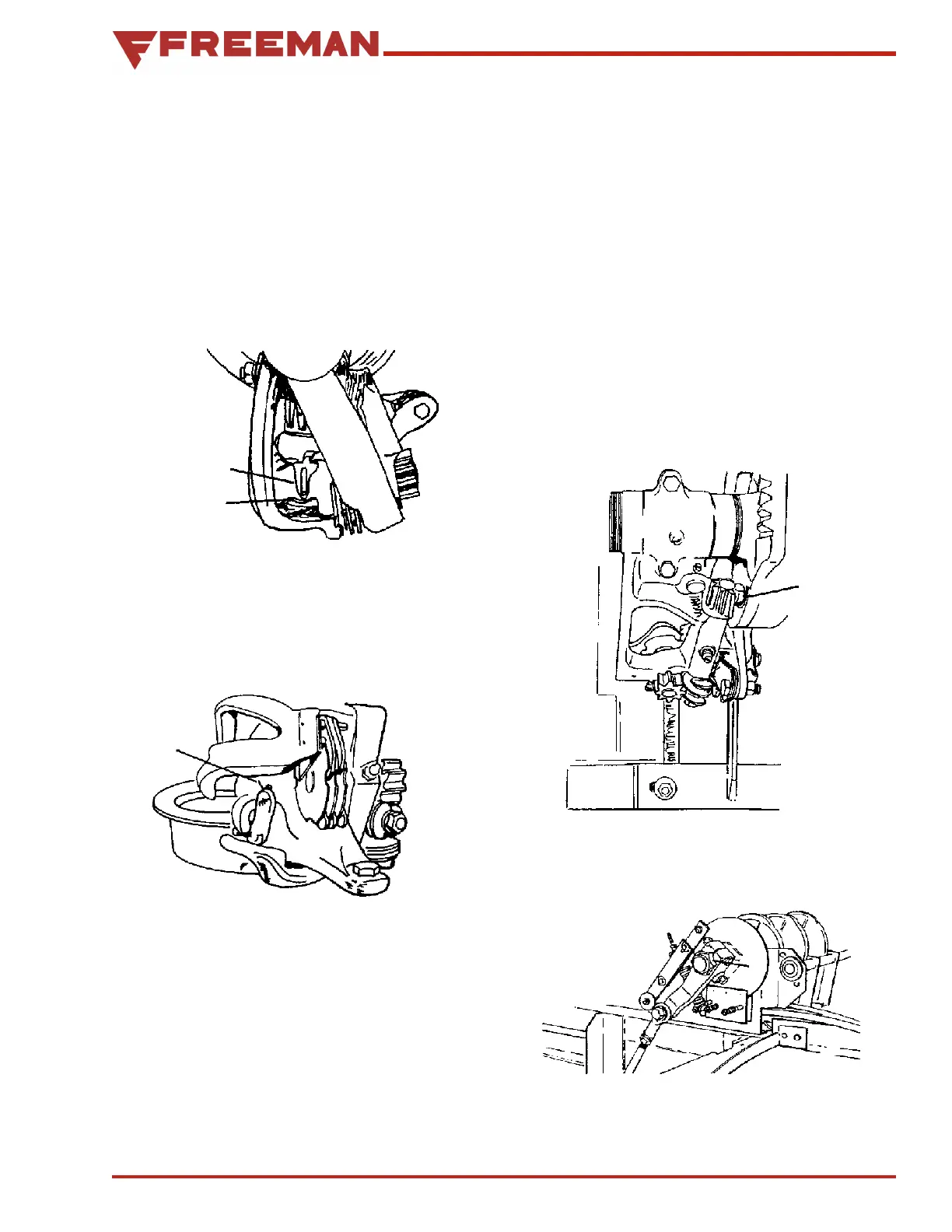

Cam Gear Adjustment

Both flat surfaces of the knotter hook and worm

gear pinions must be held flat with 0 to .005 inter-

ference on the smooth face of the cam gears (see

Figure 118).

Make this adjustment with shims between the cam

gears and knotter frames. Shimming must be done

be tween the cam gears and the knotter frames any

time a knotter is assembled. Take out excess space

between the cam gears and the knotter frames

by adjusting nut (A), see Figure 119. Tighten nut

until knotters will just hold their own weight when

rotated up to horizontal.

0.005

Figure 118. Knotter

A

Figure 119. Adjusting Nut

Loading...

Loading...