82

Rev 4/2018

SETTINGS AND ADJUSTMENTS

Bullgear Luber (if applicable)

Establish a good coating of grease on the bullgears

before the the baler is used for first time, to ensure

long bullgear life. A container of bullgear grease is

included with your baler to get you started.

The bullgear luber (see Figure 128) distributes

grease onto the bullgears through a manifold under

the bullgear hood.

Before initial baler operation, the bullgears must be

completely coated with Freeman bullgear grease,

F000007626. Do not bale until the bullgears are

covered with grease.

During the first 48 hours of bailing, grease bull-

gears every 30 minutes, and again at the end of

each shift. Greasing at the end of the shift gives

the bullgear grease an opportunity to set up and

adhere to the warm bullgears.

Once you have established a good coverage of

grease on the bullgears, greasing every four hours

of baling is usually adequate. Always grease at the

end of each shift.

NOTICE

The bullgear luber works best when the

bullgear grease is in a liquid state. If it has

hardened, the luber will not be able to apply

the grease.

WARNING

Stop the baler engine and wait for all motion

to cease before servicing or adjusting the

machine.

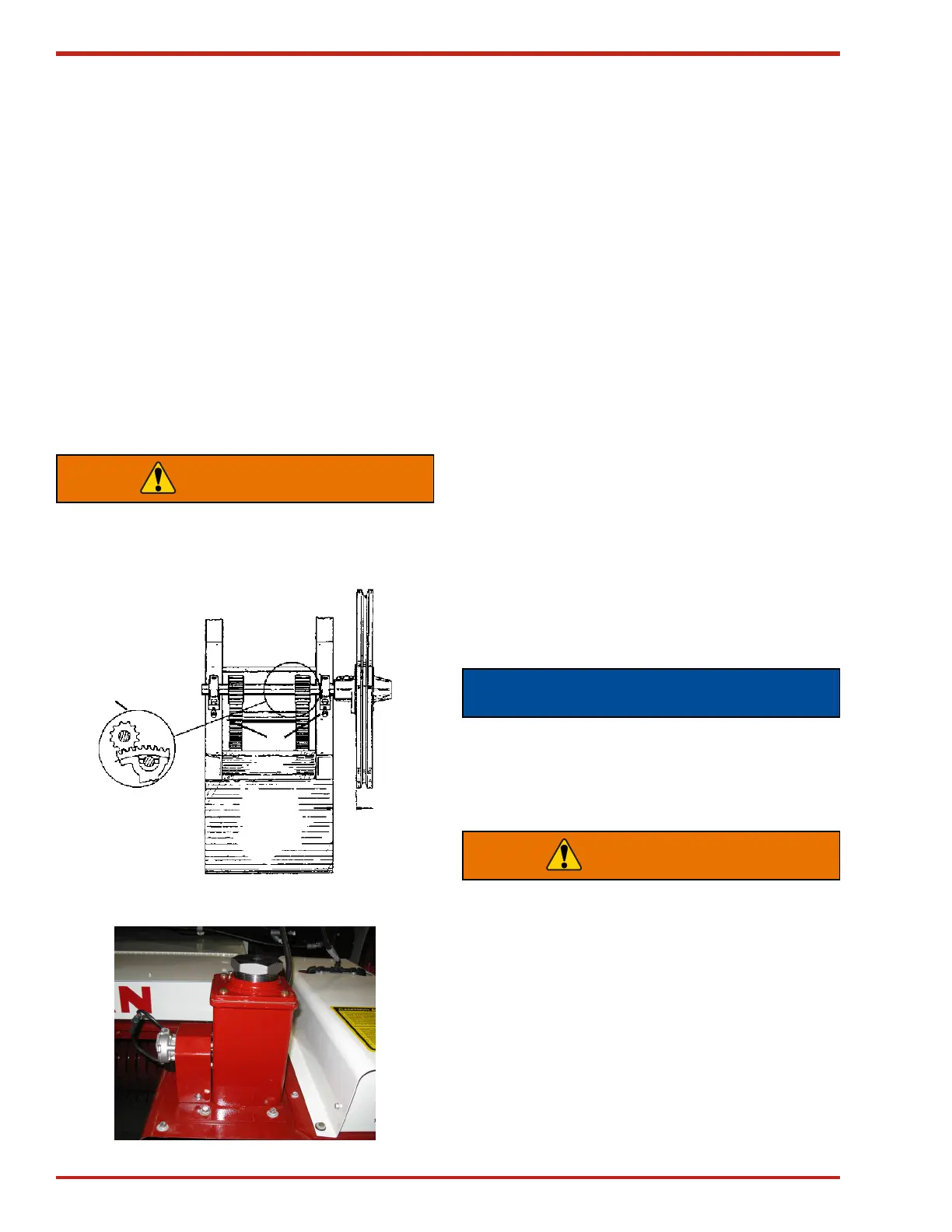

Pinion and Bullgear (if applicable)

The flywheel (see Figure 127) should be parallel to

the frame plus or minus 1/8", with pinions meshing

evenly with the bullgear teeth (A).

The lash of the pinion gears should have between

1/8" and 3/8" of free play on the rim of the flywheel

at (B). Measure this when the connecting rod is

fully extended and blocked to prevent bullgear

movement.

Correct excessive free play by adjusting set screws

(C). Be certain both sides are adjusted evenly to

avoid serious equipment damage.

WARNING

Always shut baler off when in specting,

adjusting, lubricating, or servicing the baler.

A

C

B

Figure 127. Pinion Gears

Figure 128. Bullgear Luber Tank (if applicable)

Loading...

Loading...