44

Rev 4/2018

The engine is ready for normal operation. However,

you should use extra care during the first 100 hours

of operation.

IMPORTANT! Do not let fuel tank run dry.

Check fuel gauge frequently.

During the first 20 hours, avoid sustained

maximum load operation.

1. To promote good ring seating and prevent cylinder

wall glazing, put the engine to work as soon as

possible. Avoid unnecessary idling. Turn off engine

if baler must be idled longer than 5 minutes.

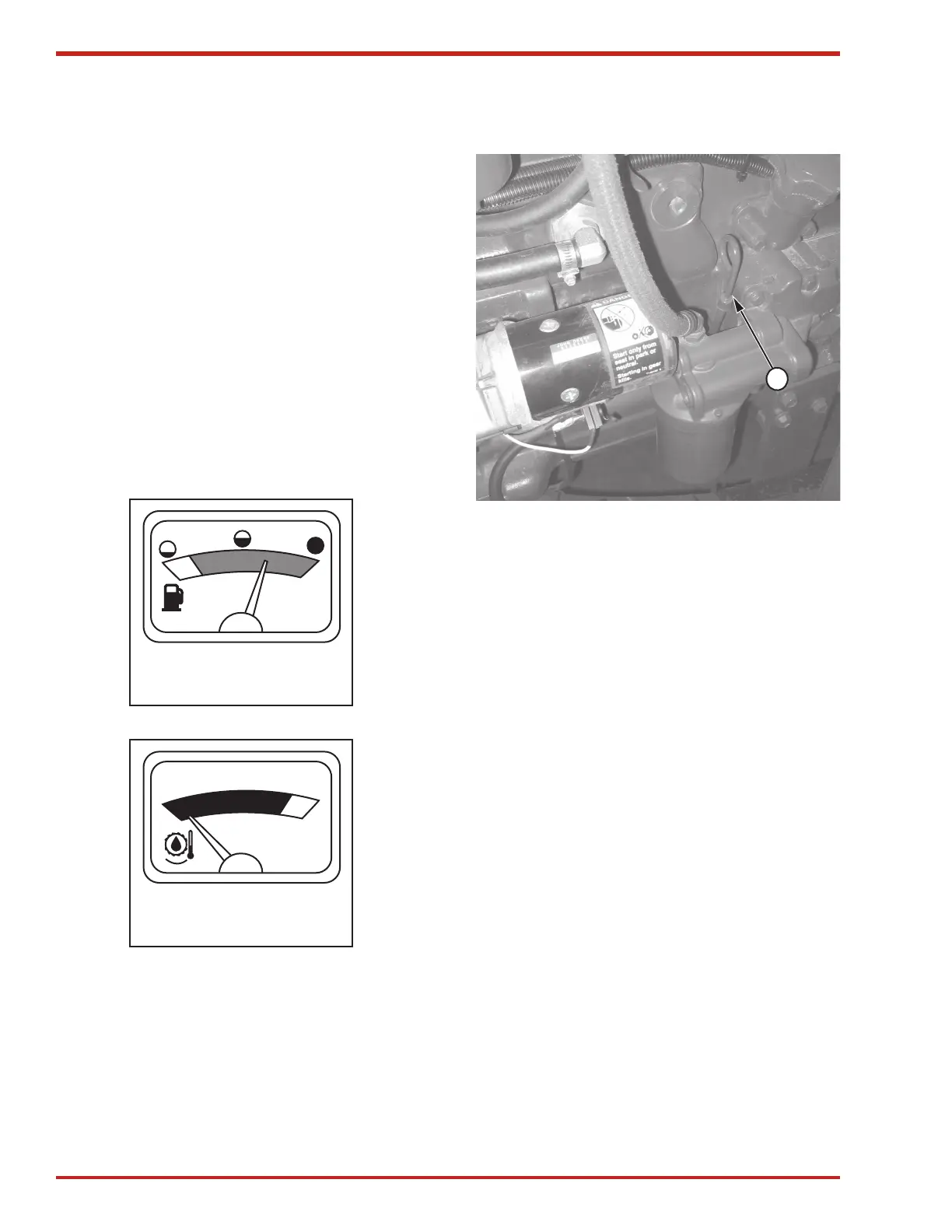

2. Watch coolant temperature gauge (see Figure 50)

closely. If gauge goes into the RED zone, slow

ground speed to reduce load.

FUEL

TEMP

Figure 50. Fuel and Temperature Gauge

A

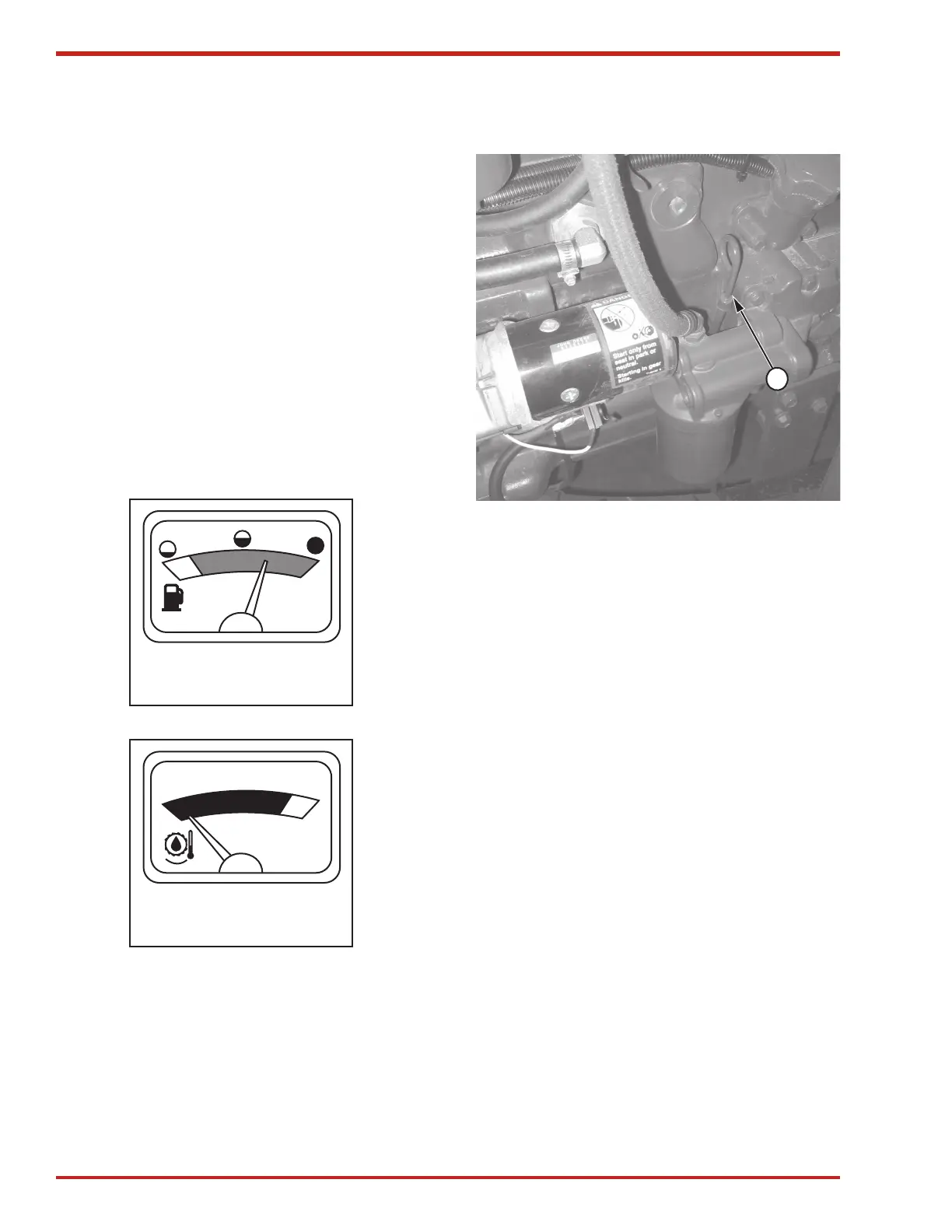

Figure 51. Engine Oil Dip Stick

IMPORTANT! Check engine oil and coolant

levels frequently. After starting the engine,

do not accelerate or apply load until the

engine oil pressure warning light is out.

Turn off engine by idling at least 1-3 minutes

before stopping engine.

Refer to Fuel, Coolant and Lubricants section

in your Engine Manufacturer's Operator's

Manual for types of fluids and oils to use.

3. This engine is factory-filled with special break-in

oil. Operate the engine at heavy loads with minimal

idling during the break-in period.

IMPORTANT! DO NOT add additional oil until

the oil level is BELOW the ADD mark on the

dipstick. Engine Break-In Oil (Allied Systems

part number 907811) should be used to make

up any oil consumed during the break-in

period. DO NOT use regular engine oil during

the break-in period of a new engine or engine

that has had a major overhaul. Regular oil

will not allow a new or overhauled engine

to properly wear during the break-in period.

DO NOT fill above the cross hatch pattern on

the dipstick. Oil levels anywhere within the

cross hatch are considered in the acceptable

operating range.

Machine Break-In

Loading...

Loading...