78

Rev 4/2018

SETTINGS AND ADJUSTMENTS

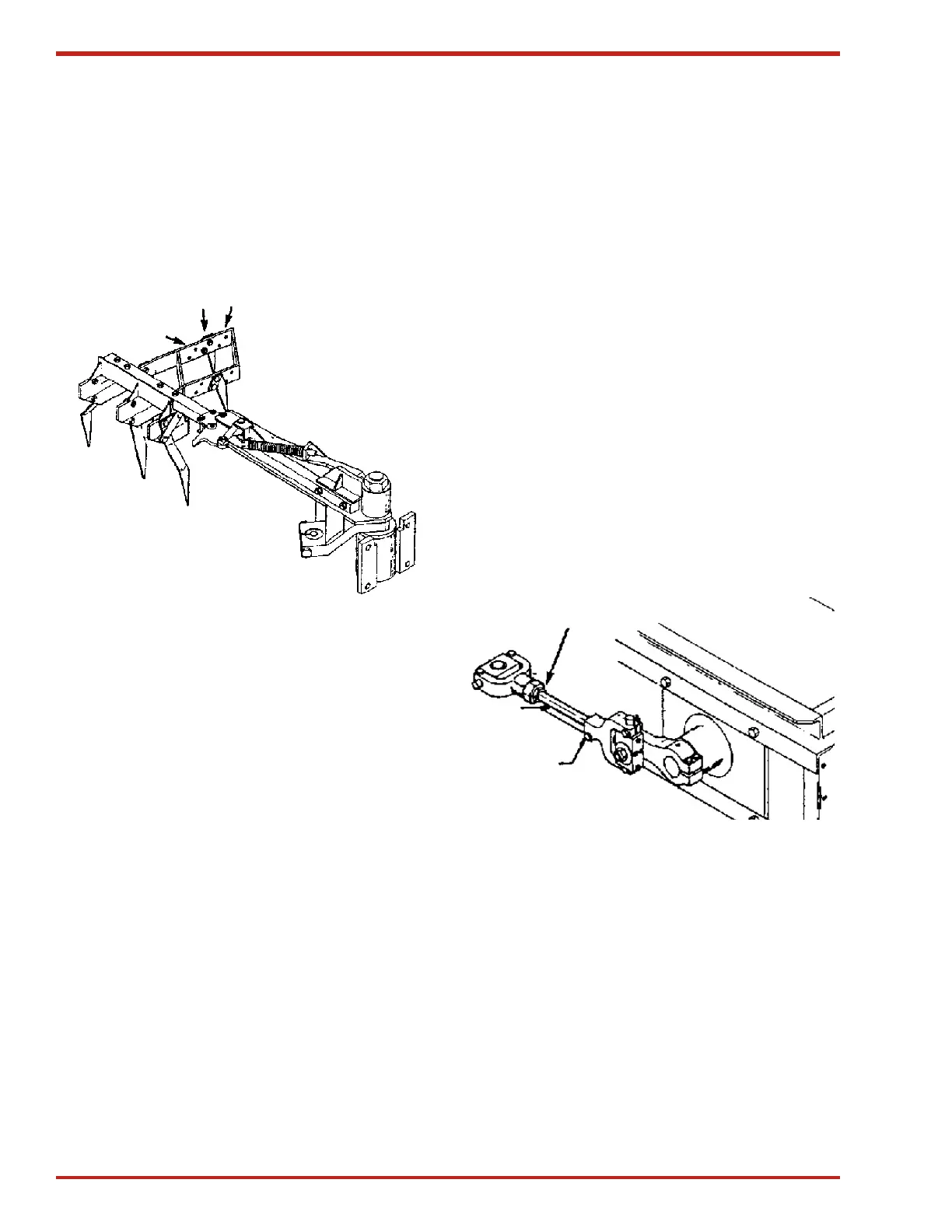

Feed Arm

The normal position of the arm is parallel to the

bale chamber when fully extended. Feed fork travel

into the bale chamber can be adjusted so that

the distance is retarded or advanced. Feed arm

adjustment can affect the shape of the bales. By

retarding the feed arm, you put more hay to the

right-hand side of the bale chamber. By advancing

the feed arm, you put more hay to the left-hand

side of the bale chamber.

Loosen bolt (A), and rotate rod (B) to give desired

position of the feed fork (see Figure 121). There

should be no end play in rod at (C).

The feed arm connecting rod swivel is adjusted

by loosening jam nut (C). Rotate the swivel nut

clockwise until tight. Then loosen the swivel nut

in a counterclockwise rotation 1/12" of a turn. To

secure, hold the swivel nut in position and retighten

the 2" jam nut (see Figure 121).

A

B

C

Figure 121. Feed Arm

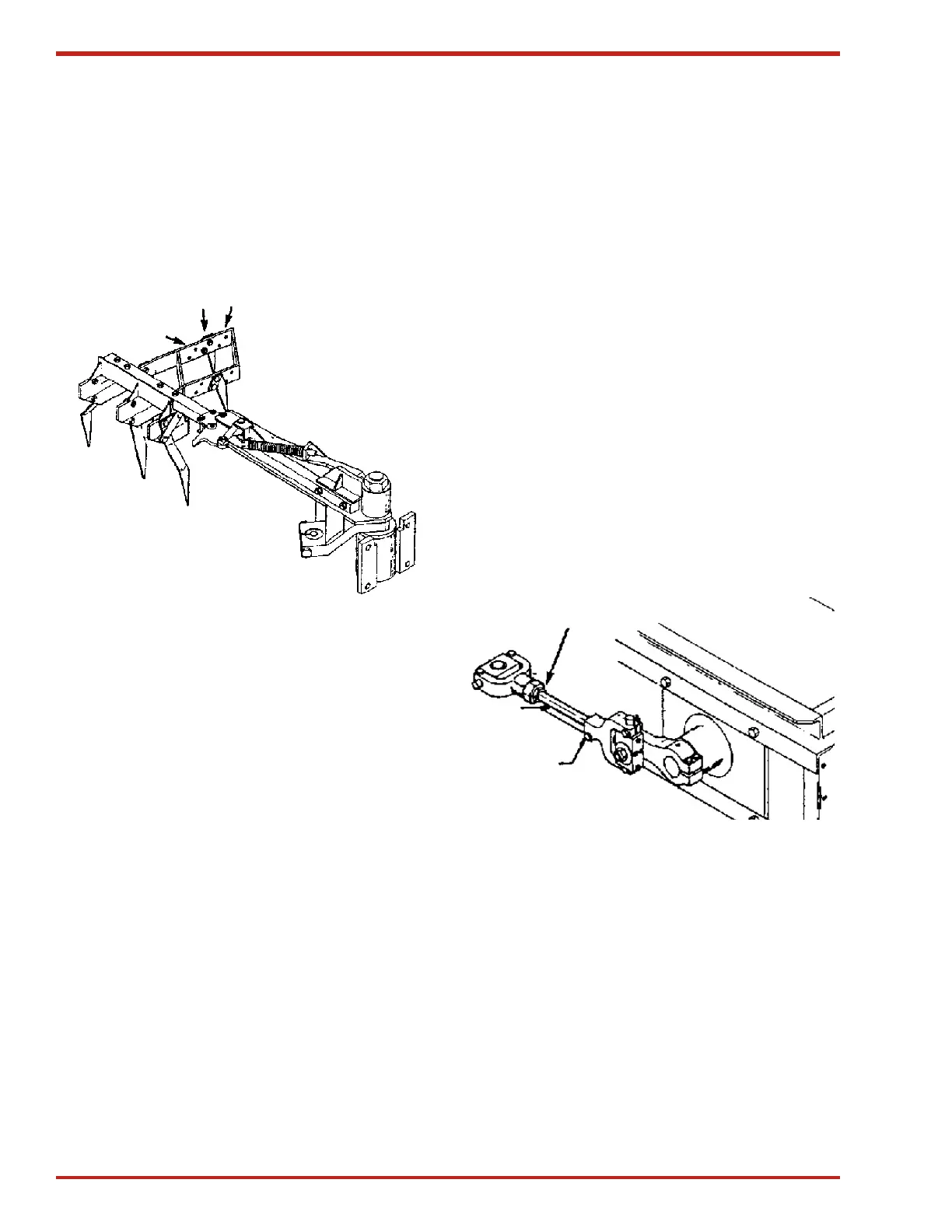

Feed Fork

The two forward tines on the feed fork are adjust-

able. The tines can be fastened to the feed fork in

position A, B or C, Figure 120. The normal position

is (B).

A

B

C

Figure 120. Feed Fork

If the bales are not uniform and more hay is needed

on the left-hand side of the bale chamber, move

both tines to posi tion (B). If more hay is needed

on the right-hand side of the bale chamber, move

both tines to position (A). Some ex perimenting may

be required to properly adjust the tines.

After adjusting the feed fork tines, run the feed arm

through one complete cycle by turning the flywheel

counterclock wise to make sure it does not interfere

with any other parts.

Additional adjustments can be done with the feed

arm.

Loading...

Loading...