Rev 4/2018

71

Knotter Settings

Knotter Settings

The following instructions will help you understand

the twine knotter and the adjustments necessary to

maintain and keep the system tying at the optimum

level of performance. Periodic checks of these

adjustments will help alleviate tying problems and

reduce the risk of equipment damage.

NOTE: Adjustments may vary for different

crops.

Needle

NOTE: Before timing the needles, be sure

the needles are in adjustment. For adjusting

the needles see "Twine Needle Adjustment"

on page 74.

To Check Needle Timing:

Trip the knotter clutch (see Figure 99) by raising

the trip bar (see Figure 101 on page 72) until the

notch is positioned over the knurl. Turn the flywheel

counterclockwise until the tips of the needles are

even with he bottom of the bale chamber (see

Figure 98).

Plunger

face

Gussets

Needle

Figure 98. Needle and Plunger

The leading edge of the plunger's gussets must

be 1/4" to 4" past the tips of the needles when the

plunger is on the compression stroke. The needles

are late if the leading edge of the plunger gussets

is more than 3" past the tips of the needles. The

needles are early if they are less than 1/4" past

the leading edge of the plunger gussets. Con sult

the decal on the left-hand side of the baler.

Needle Timing Adjustment

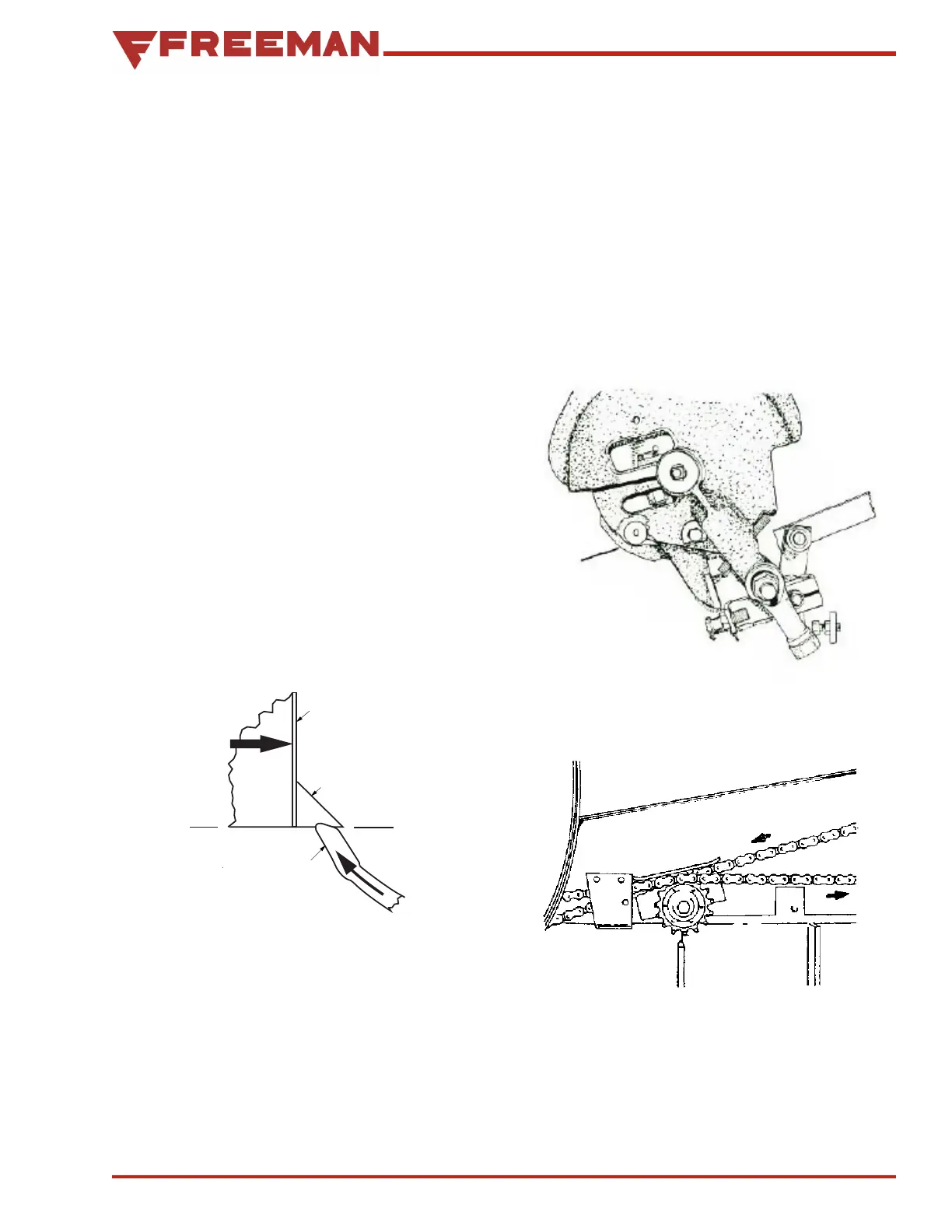

If the needles are late, retard the knotter drive chain

on the knotter sprocket one link. If the needles are

early, ad vance the chain one link.

Replace the chain on the sprocket and connect it.

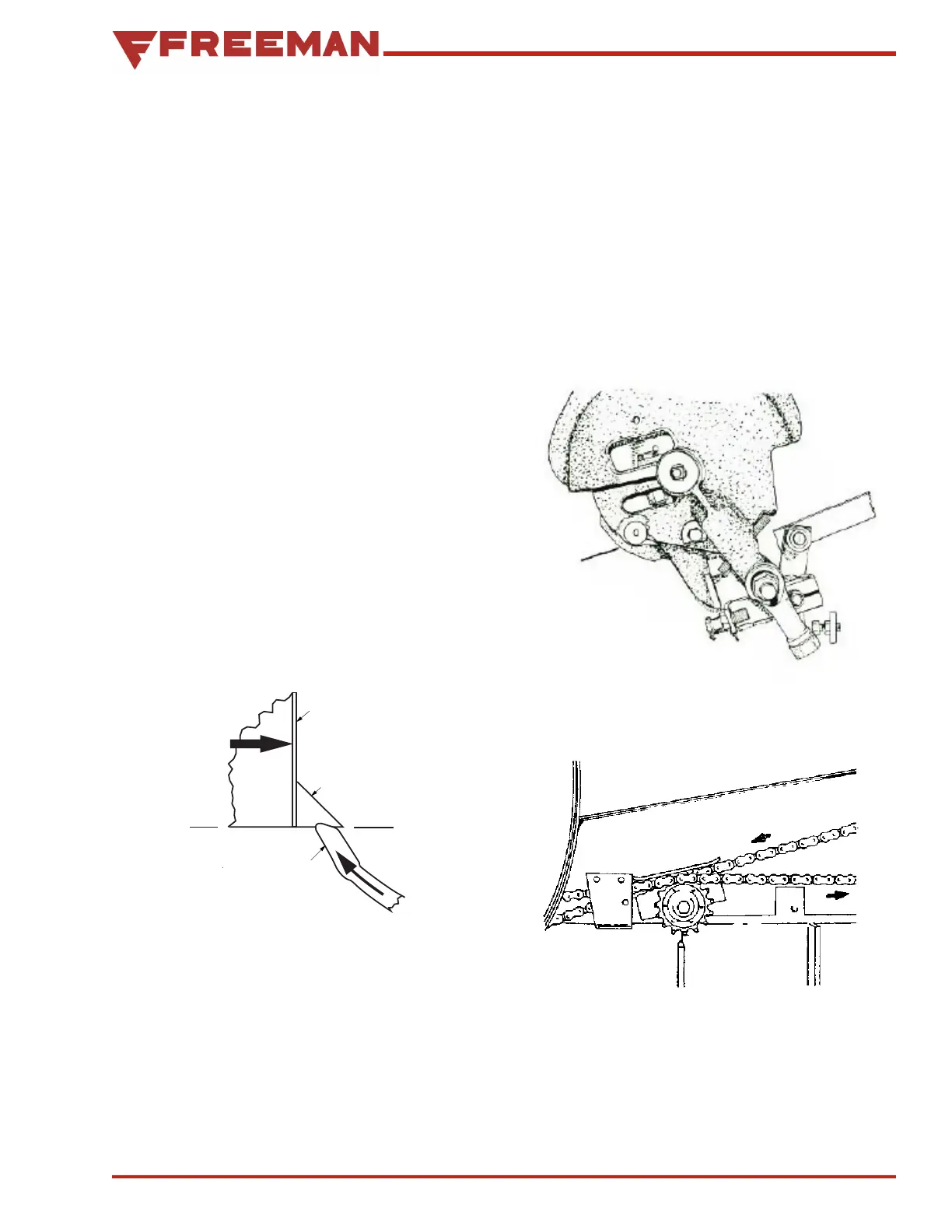

Be sure that the clutch pawl roller (see Figure 99)

is seated in the notch in the clutch and that the

chain is connected on the idle side and on top of

the idler sprockets (see Figure 100).

Clutch

Pawl

Roller

Figure 99. Knotter Clutch

Figure 100. Knotter Drive Chain

Trip the knotter clutch and turn the flywheel coun-

terclockwise. Recheck the timing. Repeat the above

procedures until adjustment is correct.

Loading...

Loading...