06-87

If the amount of recovered refrigerant is available that was pulled out of outdoor unit

which compressor was replaced.

(When the refrigerant is recovered by refrigerant recovery machine, and its weight is measured.)

If the amount of recovered refrigerant from outdoor unit that compressor was replaced is not sure.

>>> Once recover all units' refrigerant, and then recharge the calculated amount of

refrigerant again after vacuuming.

>>> Perform vacuuming of repaired outdoor unit thoroughly ,

and add the refrigerant with the recovered amount.

6-4-3 Work procedure after the backup operation

1. Refrigerant shortage at the backup operation

1-1. On Cooling operation

When excessive refrigerant accumulates in the defective outdoor unit during the backup operation,

it becomes refrigerant shortage operation.

Method of judging refrigerant shortage from Service tool (or Web monitoring tool) is as follows.

2. Refrigerant charging after the compressor replacement.

When the refrigerant leaks at the time of replacing the defective compressor,

charge the refrigerant as follows depending on the situation.

There is no liquid refrigerant in the outdoor unit receiver tank.

>>> When SV3 is ON, TH5 TH6 TH7 TH4

Running indoor unit's EEV is fully open condition.

>>> It displays corresponding indoor unit's EEV on the chart at the bottom of the monitor.

If there is no sign of closing the EEV from fully opened condition, the refrigerant has a shortage.

It often creates "Low pressure protection stop" at start up or after oil recovery operation.

>>> When LPS 0.1MPa at start up, the compressor stops.

1-2. On Heating operation

There is no liquid refrigerant in the outdoor unit receiver tank.

>>> When SV3 is ON, TH5 TH6 TH7 TH4

EEV1 of outdoor unit is 500pulse. (100%).

Suction superheat is too high.

>>> When both TH4 TH11 and TH11 TH12.

It often creates "Low pressure protection stop" at start up or after oil recovery operation.

>>> When LPS 0.1MPa at start up, the compressor stops.

TH4, 5, 6, 7, 11, 12 : Outdoor unit thermistor

SV3 : Solenoid valve for liquid level detection

of the receiver tank.

EEV1 : Main EEV of the outdoor unit.

The meaning of the sign

<How to respond, when refrigerant is deficient>

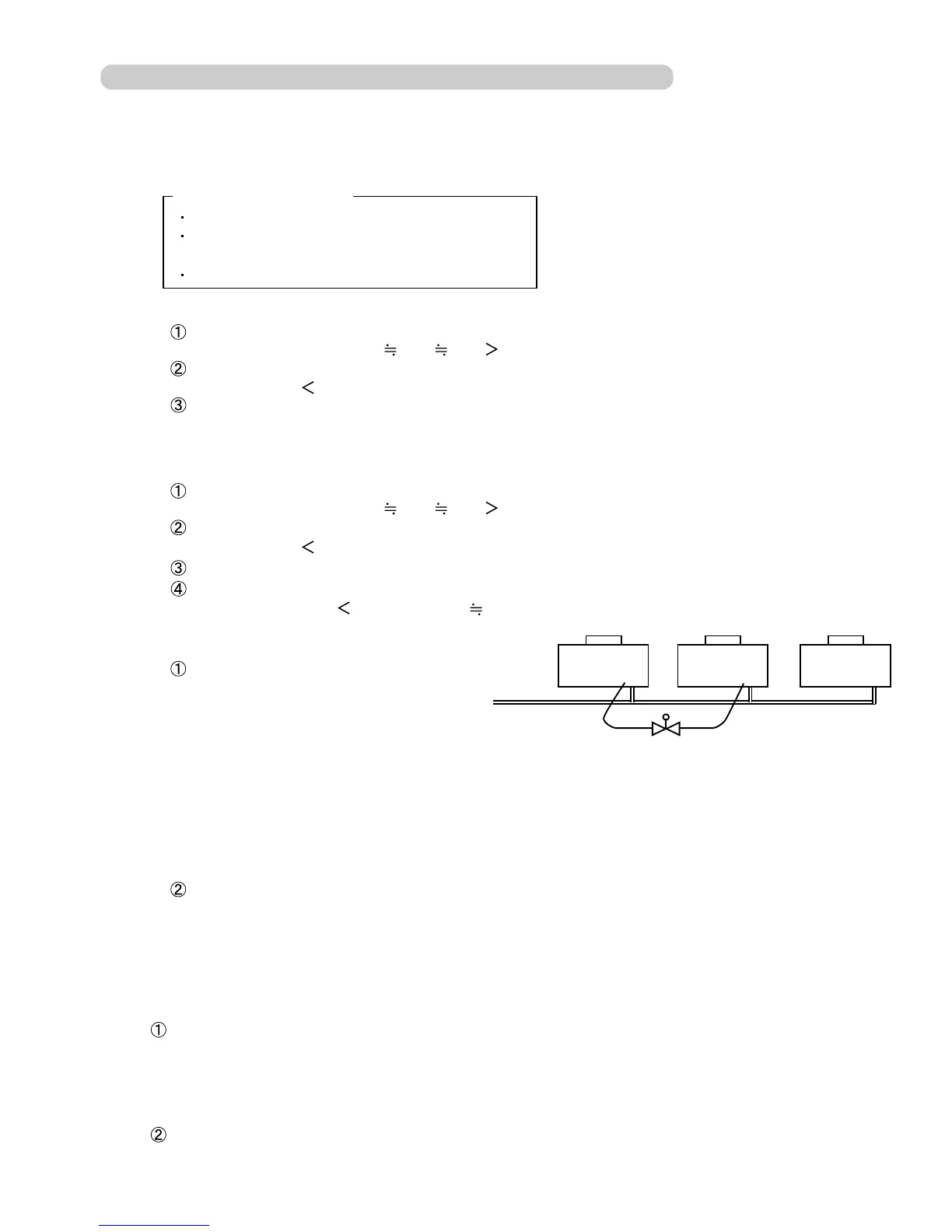

Reuse the refrigerant of the broken master unit.

Connect the liquid pressure service port of the broken master unit and the low pressure service port

of the substitutional master unit by charging hose, placing the valve on the way.

>>> Refrigerant release from the receiver tank of the broken master unit.

(Refrigerant is removed until refrigerant shortage is resolved)

If refrigerant is still deficient, connect the high pressure service port of the broken master unit

and the low pressure service port of the substitutional master unit by charging hose,

and refrigerant is removed.

Connect the high pressure service port of the broken master unit and the low pressure service port

of the substitutional master unit by charging hose, placing the valve on the way.

>>> Refrigerant release from the heat exchanger of the broken master unit.

(Refrigerant is removed until refrigerant shortage is resolved)

Not available to reuse.

>>> New refrigerant is encapsulated at substitutional master unit,

and encapsulating amount is recorded.

Broken

master unit

Substitutional

master unit

Slave

unit #1

Loading...

Loading...