SERVICE PARTS INFORMATION 5

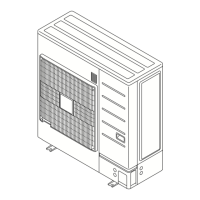

Indoor Unit Electronic Expansion Valve

(EEV)

Check Point 2 : Check Coil of EEV

Remove connector, check each winding resistance of Coil.

If Resistance value is abnormal, replace EEV.

Yellow - Brown

Orange - Red

Blue - Brown

White - Red

Read wire

150 ± 10%

Resistance value (20°C)

Check Point 1 : Check Connections

Check Connectors

(Loose connector or open cable of CN14 for Duct type.)

Duct

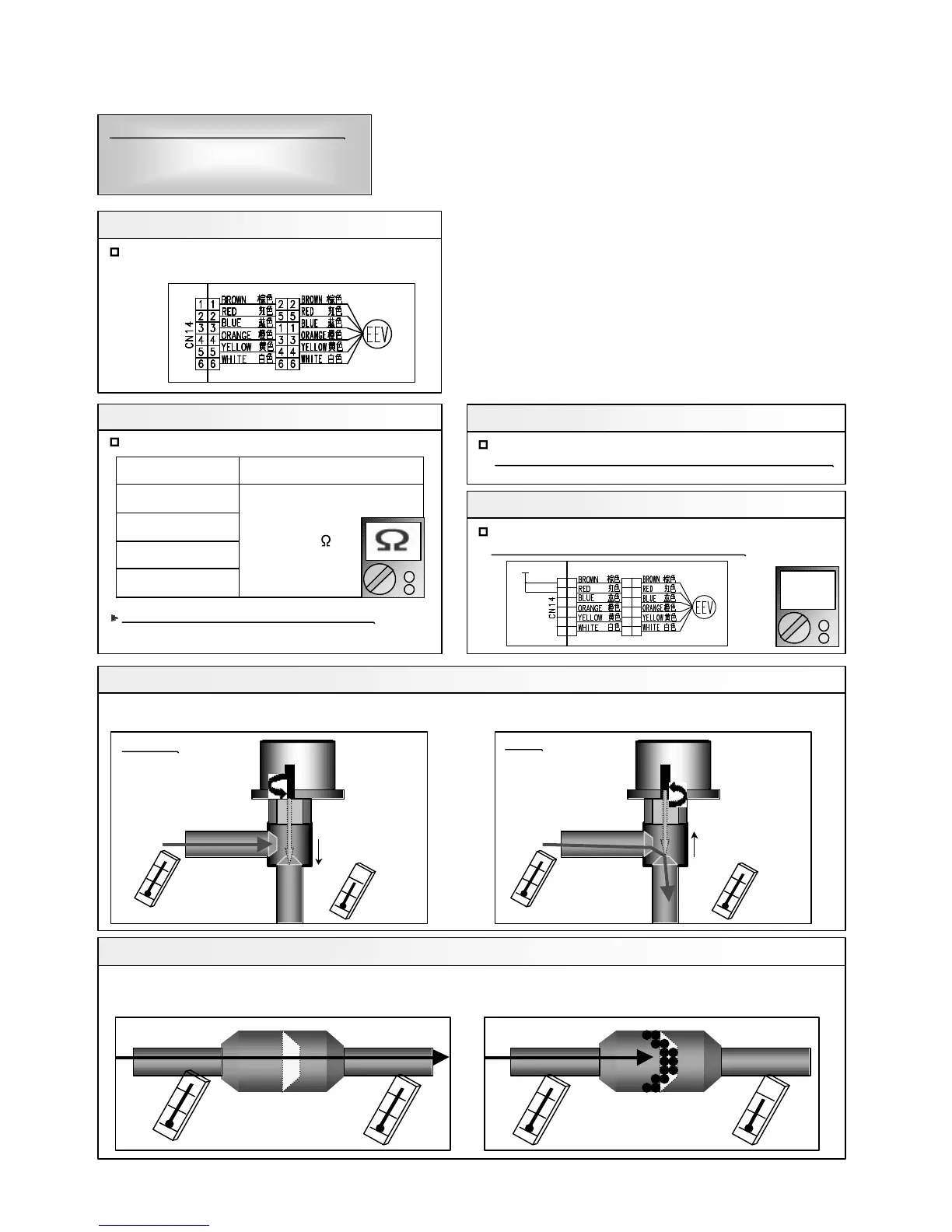

Check Point 5 : Check Opening and Closing Operation of Valve

When Valve is closed,

it has a temp. difference between Inlet and Outlet.

Check Voltage from Controller PCB

Remove Connector and check Voltage (DC12V).

>> If it does not appear, replace Controller PCB.

Check Point 3 :

Check Point 4 :

Check Noise at start up

Turn on Power and check operation noise.

>> If an abnormal noise does not show, replace Controller PCB.

DC

Pipe (In) Pipe (Out)Pipe (In) Pipe (Out)

Check Point 6 : Check Strainer

Strainer normally does not have temperature difference between inlet and outlet as shown in (1), but if there is a difference

as shown in (2), there is a possibility of inside clogged. In this case, replace Strainer.

(1) (2)

If it is open, it has no temp. difference between Inlet and Outlet.

06-92

Pipe (In)

Pipe (Out)

CLOSE

Example : Hot gas

Pipe (In)

Pipe (Out)

OPEN

Example : Hot gas

12V

2

5

1

3

4

6

2

5

1

3

4

6

1

2

3

4

5

6

1

2

3

4

5

6

Loading...

Loading...