SCANNER SAFETY AND LOCAL CONTROLS

When the scanner is raised or spans open floor areas, fall protection needs to be

considered in accordance with local mill rules and regulations.

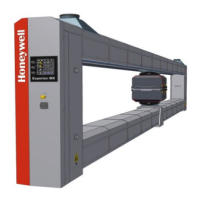

Table 1 lists and describes hazard zones.

Table. 1. Scanner Frame: Mechanical Motion Precautions

Work in this area has dangerous pinch points

associated with pulleys, belts and moving

carriage parts which can cause serious injury.

Work in this area requires lockout/tagout of motor

drive or higher electrical circuit.

This area has the potential for body crush

between moving heads and end support.

Buffer stops are set at factory to provide 0.5 m

(19.7 in) safety clearance.

Work in this area requires lockout/tagout of motor

drive or higher electrical circuit.

Work in this area has potential for impact from

moving heads. Pinning of worker between

heads and other close mill equipment is also a

concern.

Work in this area requires lockout/tagout of motor

drive or higher electrical circuit.

Typically, work done at heights > 3 m (9.84 ft),

or above dangerous equipment require use of

a fall protection system. Use caution when

working on elevated scanners or spans over

open floor sections.

Refer to local mill safety rules for use of ladder and

worker height restrictions with or without fall

protection system. Typical systems include fall

arrest harnesses, and anchors or fall restraint

systems.

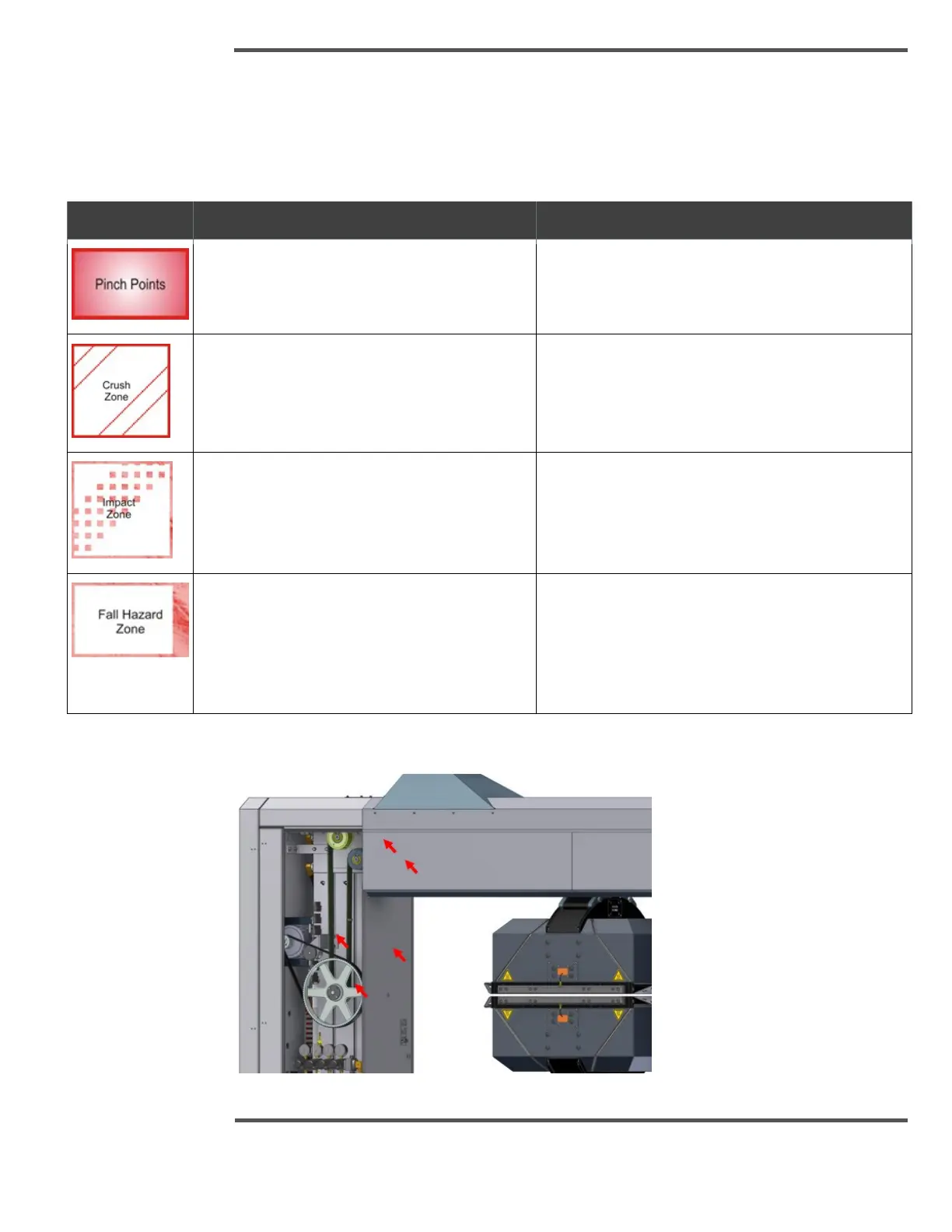

Figure 6 through to Figure 10 shows a variety of pinch point locations.

Fig. 6. Drive belt Pinch Points

Loading...

Loading...