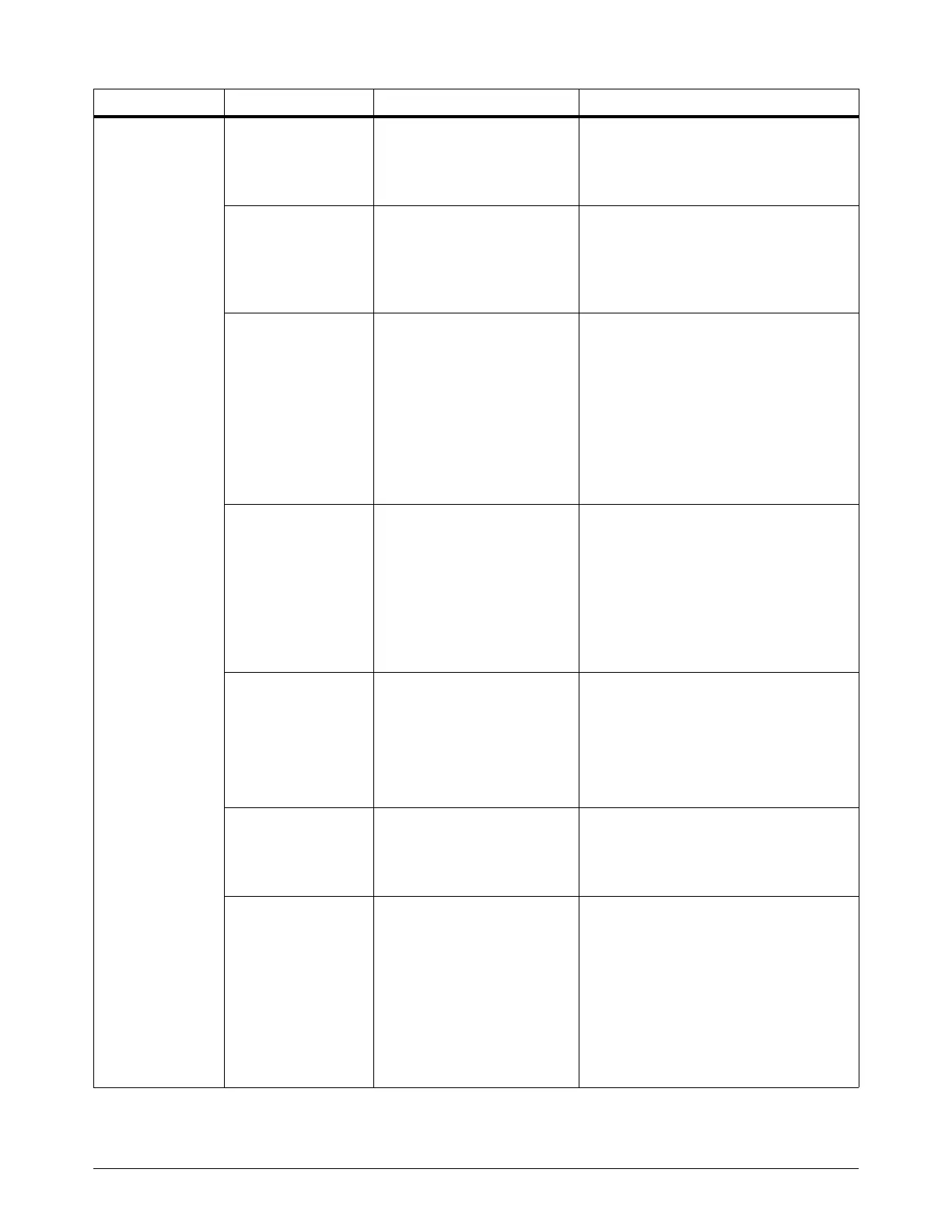

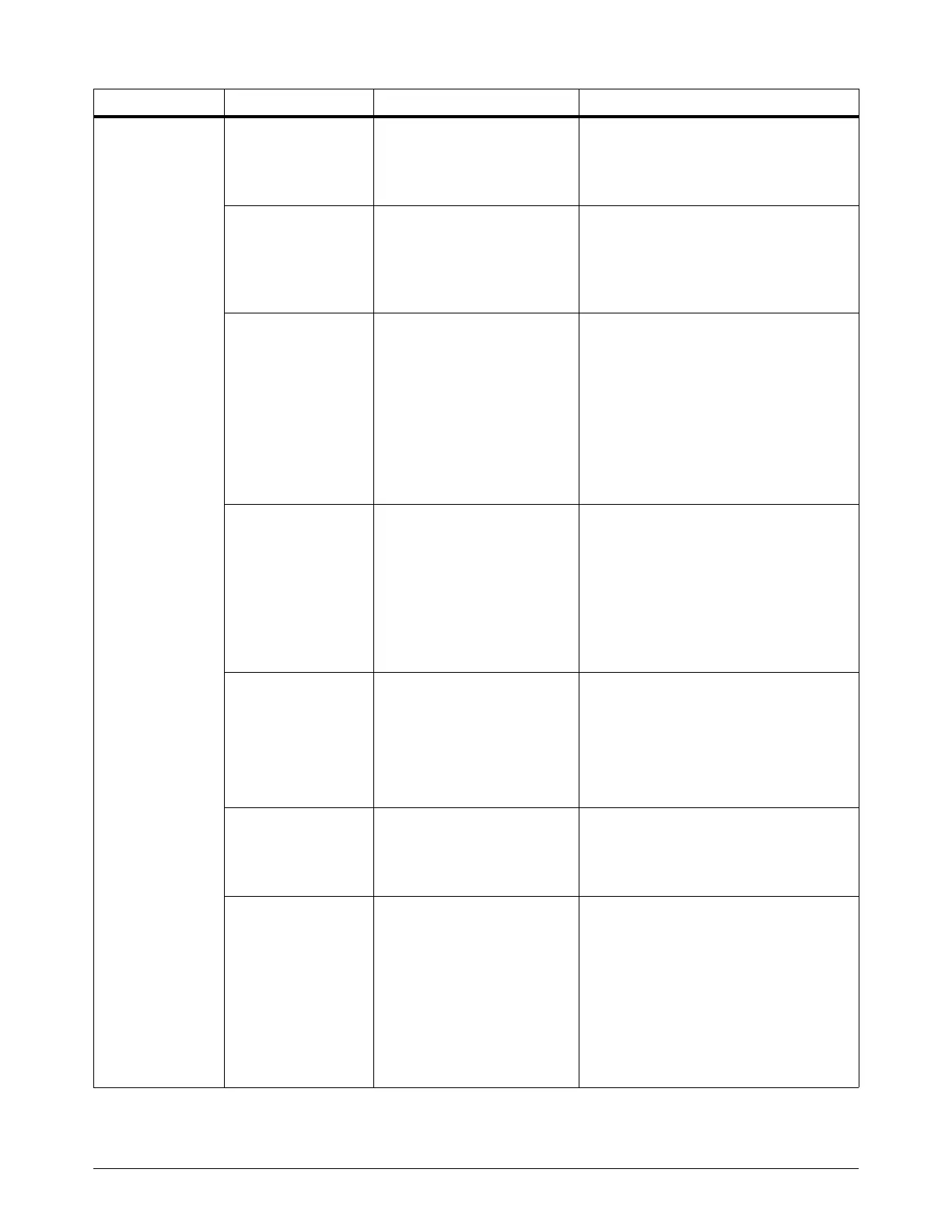

Troubleshooting for Common Problems

Powermax65/85/105 SYNC Troubleshooting Guide 810430 67

Gas flows when

you fire the torch,

but there is no

plasma arc, or you

lose the arc

quickly.

The cartridge is worn

or has damage.

• The cartridge is not

installed correctly.

• The cartridge is at

end-of-life.

• Make sure that the cartridge is not

too loose or too tight.

• Install a new cartridge.

There is damage to

the cartridge or to

the torch lead.

• The electrode in the

cartridge is not moving

correctly.

• There is damage to the

torch lead.

•Do Test 6 – Torch stuck open (TSO)

or torch stuck closed (TSC) on

page 98.

The gas flow is too

high or is not

sufficient.

• The gas pressure is too

high or too low.

• The gas supply line has

leaks or blockages.

• Make sure that the inlet gas pressure

stays between 7.6 bar – 8.3 bar

(110 psi – 120 psi) while gas is

flowing.

• Make sure that the gas supply is not

more than 9.3 bar (135 psi).

• Repair gas leaks and blockages.

• Adjust the gas pressure on the

plasma power supply manually.

The gas quality is

unsatisfactory.

• The filter element in the

air filter is dirty.

• Oil, moisture, or other

contaminants are in the

gas supply line.

• Replace the air filter element.

•Add additional, external filtration that

is applicable for the work

environment. Refer to the

Powermax65/85/105 SYNC

Operator Manual (810470).

• Flush the gas supply line with

nitrogen to remove oil and moisture.

The input power is

not sufficient.

The electrical supply

installation for one or more of

the following is not sufficient:

• Circuit breaker or fuse

• Supply wire

• Extension cord

• Refer to the installation

specifications in the

Powermax65/85/105 SYNC

Operator Manual (810470).

An internal power

component is

defective.

• The inverter IGBT

module is defective.

•The power PCB is

defective.

• Use an IGBT tester to do a test of

the inverter IGBT module.

There is a capacitor

voltage imbalance on

the power PCB.

• Resistors on the power

PCB are defective.

• The bulk capacitors are

defective.

Do the following tests. If the voltage

across the bulk capacitors is not

balanced, replace the power PCB.

•Do Test 1 – Voltage input on

page 78.

•Do Test 2 – DC power bus on

page 83.

•Do Test 3 – Output diodes on

page 90

Problem Meaning Causes Solutions

Loading...

Loading...