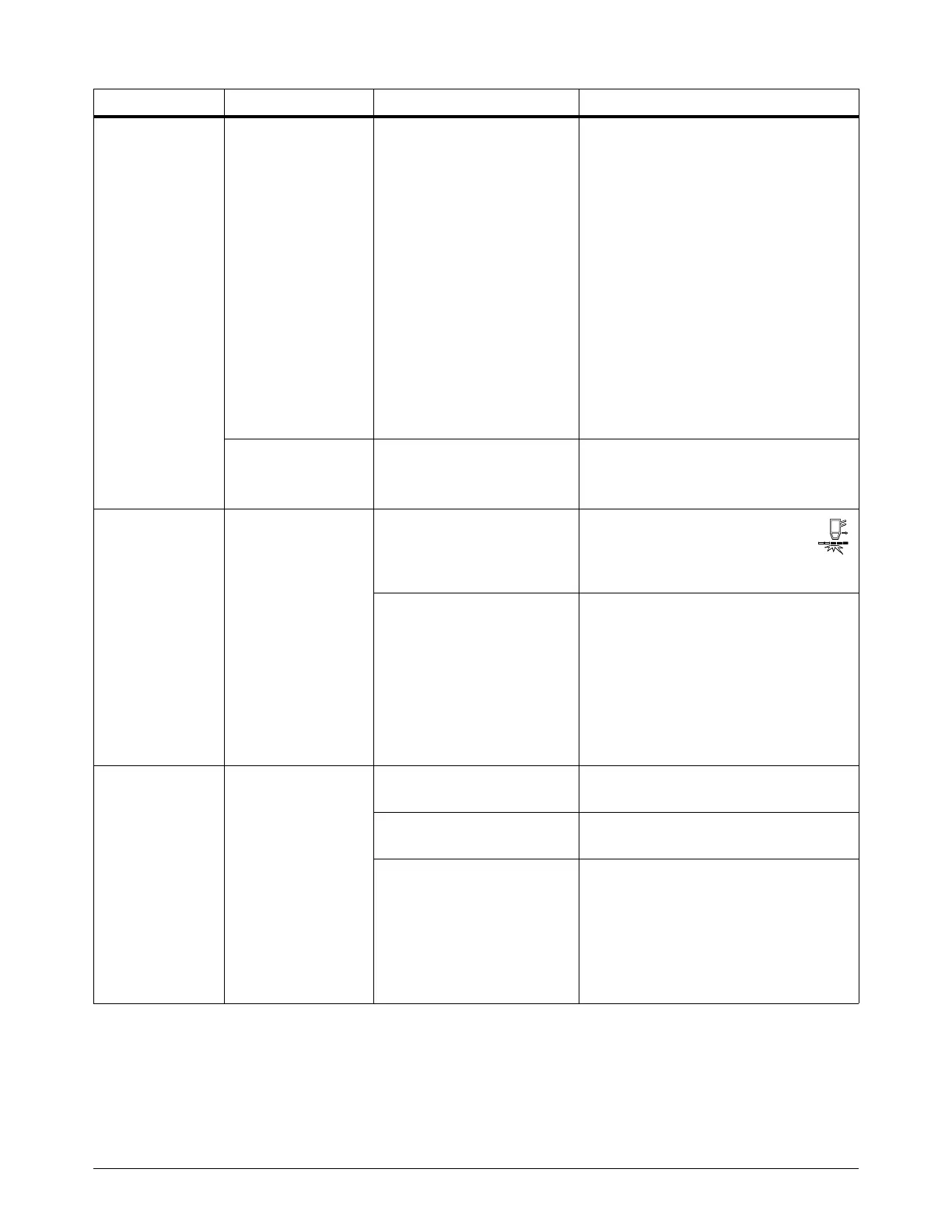

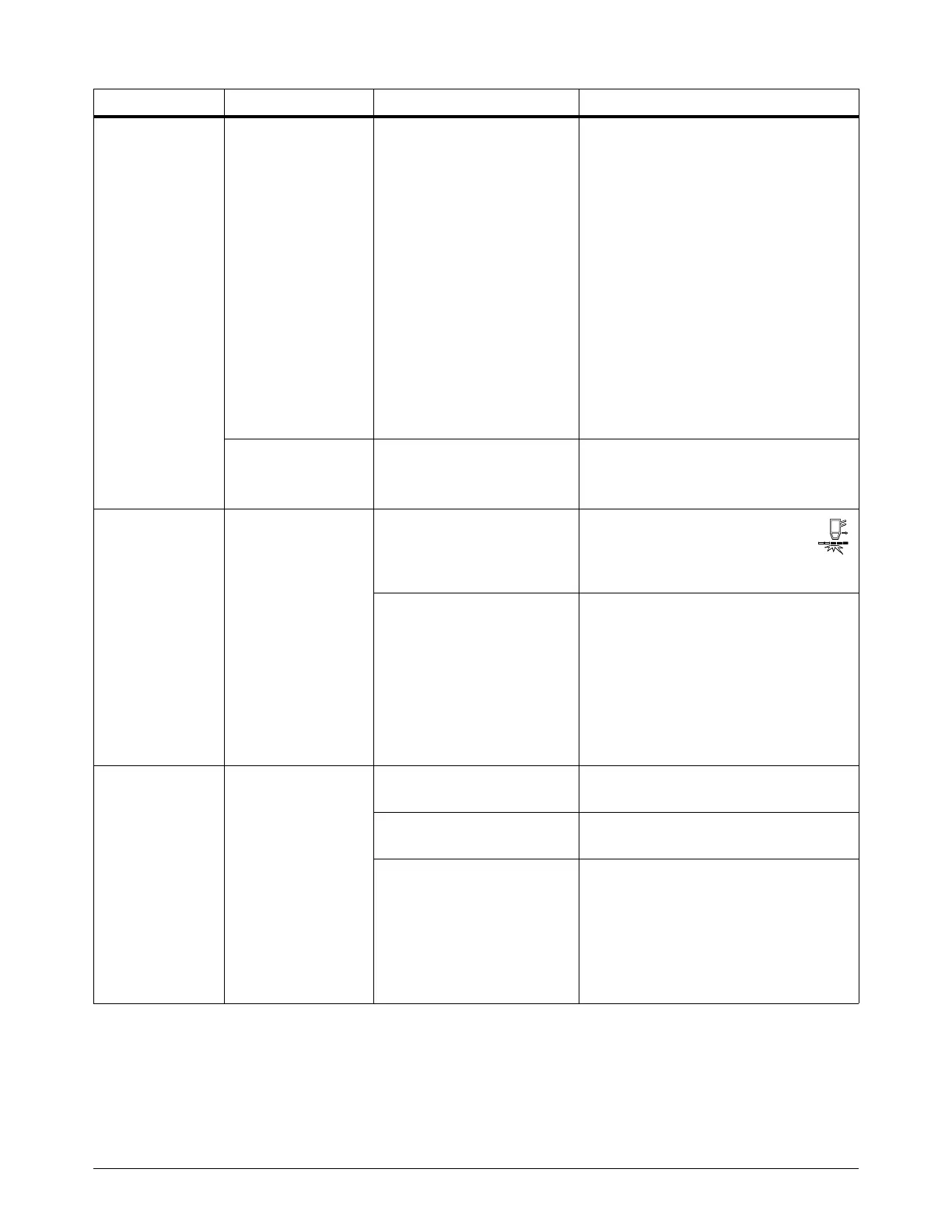

Troubleshooting for Common Problems

68 810430 Troubleshooting Guide Powermax65/85/105 SYNC

The plasma arc

goes out while

you are cutting, or

the torch will

intermittently not

fire.

The plasma arc

cannot keep contact

with the workpiece.

• The work lead is

defective. Or the work

lead connection is not

sufficient for some

reason.

• Expanded Metal mode is

necessary for the

material you are cutting.

• If possible, move the work clamp

closer to the area of the workpiece

you are cutting.

• Examine the work lead for a loose

connection at the plasma power

supply and at the work clamp.

• Clean the area where the work

clamp comes into contact with the

workpiece or cutting table. Remove

any rust, paint, or other residue.

Make sure that there is good

metal-to-metal contact.

• Put the system in Expanded Metal

mode if the metal you are cutting has

a slotted or mesh pattern, or if it has

a lot of holes.

The fan is

overloading the

flyback circuit.

• The fan is defective. • Do Test 11 – Fan on page 120.

•Do Test 5 – Flyback circuit (DC

minor voltages) on page 94.

The system is in

Expanded Metal

mode, but the

torch does not

keep the plasma

arc when you

move the torch off

of the metal.

The Expanded Metal

mode feature is not

operating correctly.

•The operating mode

setting on the plasma

power supply is not

correct.

• Make sure that the operating

mode is correctly set to

Expanded Metal mode.

•The DSP PCB is

defective.

•The power PCB is

defective.

Do the following tests, and replace

defective components as necessary:

•Do Test 1 – Voltage input on

page 78.

•Do Test 2 – DC power bus on

page 83.

•Do Test 3 – Output diodes on

page 90.

You l os t th e

plasma arc while

cutting, but the

torch produces an

arc when you fire

the torch again.

There is a problem

with the cartridge,

the air filter element,

or the input gas

pressure.

• The cartridge is worn or

has damage.

• Replace the cartridge.

• The filter element in the

air filter is dirty.

• Replace the air filter element.

• The gas pressure is too

low or too high.

• Adjust the gas pressure on the

plasma power supply manually.

• For optimum system performance,

make sure that the inlet gas pressure

stays between 7.6 bar – 8.3 bar

(110 psi – 120 psi) while gas is

flowing.

Problem Meaning Causes Solutions

Loading...

Loading...