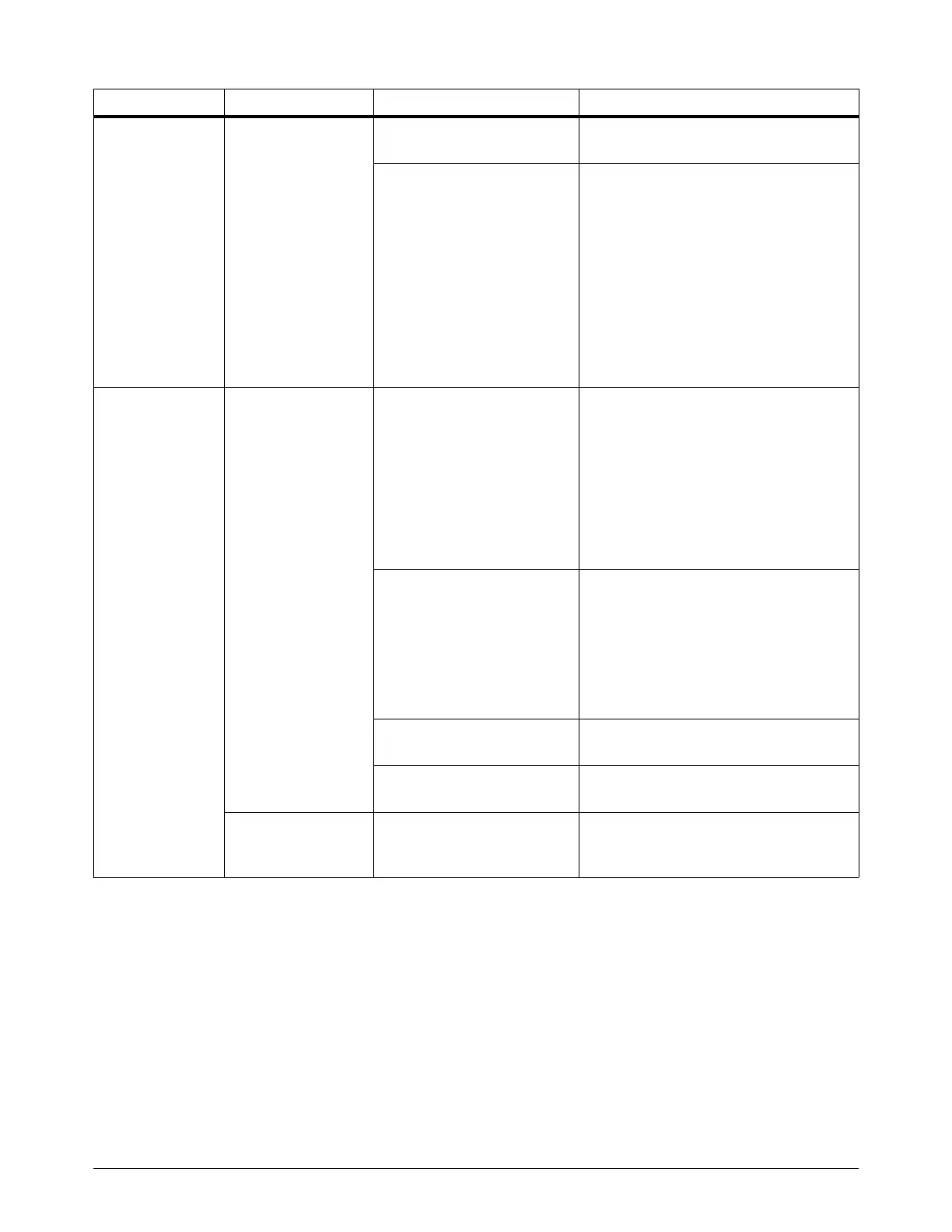

Troubleshooting for Common Problems

Powermax65/85/105 SYNC Troubleshooting Guide 810430 69

The plasma arc

makes sputtering

and hissing

sounds.

There is a problem

with the air filter

element, or it is

necessary to clean

the input gas supply.

• The filter element in the

air filter is dirty.

• Replace the air filter element.

• There is moisture in the

gas supply line.

• Examine the gas supply line for signs

of moisture. Clean or replace

external filtration components as

necessary.

• Flush the gas supply line with

nitrogen to remove oil and moisture.

• If necessary, add additional, external

filtration that is applicable for the

work environment. Refer to the

Powermax65/85/105 SYNC

Operator Manual (810470).

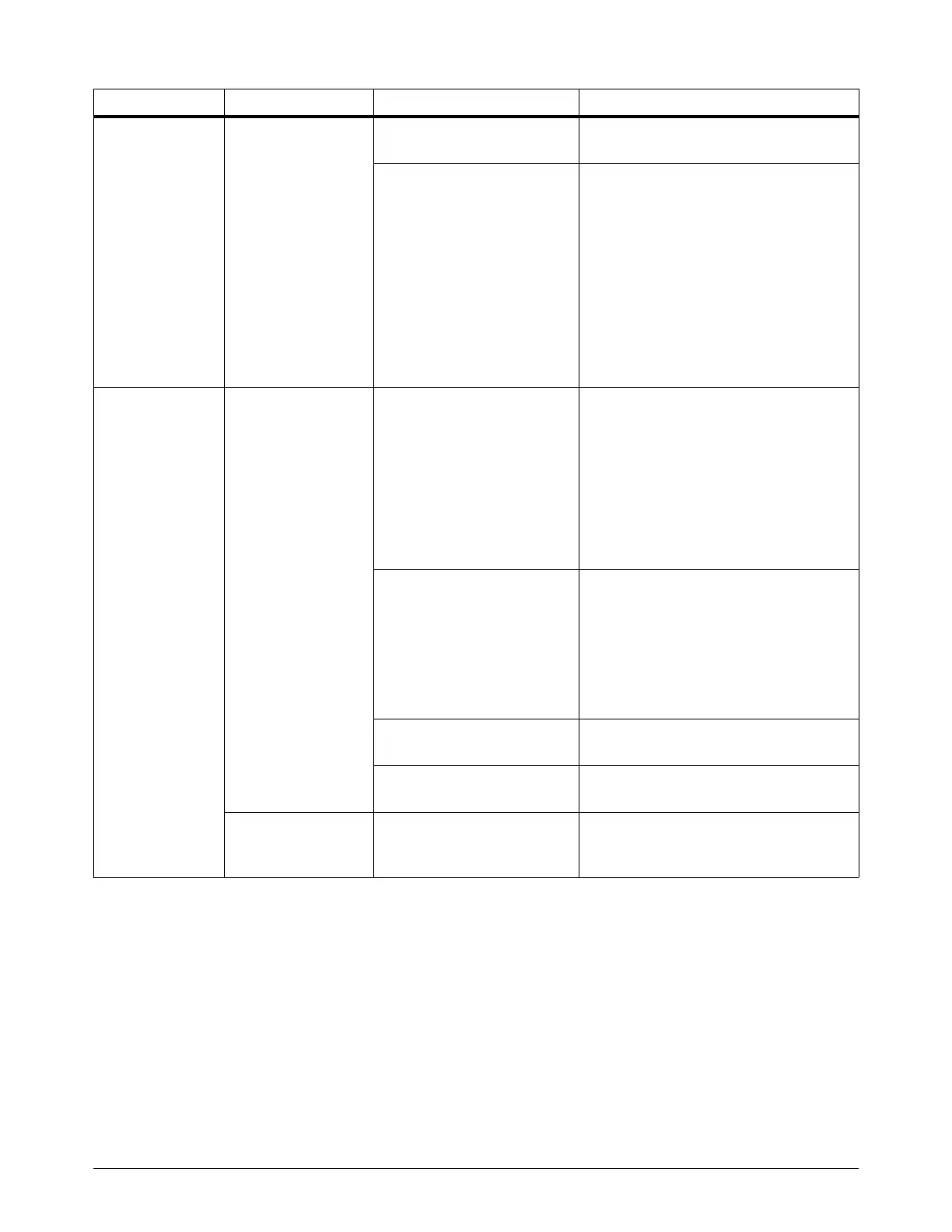

The system is not

cutting at full

cutting power,

and the plasma

arc does not time

out after

5seconds.

The system is not

connected to ground

sufficiently.

•The work lead

connection is not

satisfactory.

• If possible, move the work clamp

closer to the area of the workpiece

you are cutting.

• Clean the area where the work

clamp comes into contact with the

workpiece or cutting table. Remove

any rust, paint, or other residue.

Make sure that there is good

metal-to-metal contact.

• The work lead has

damage.

Measure the resistance across the work

lead. If the resistance is greater than

3 ohms (), repair or replace the work

lead. Identify the work lead connection

on the power PCB as follows:

• Powermax65/85 SYNC models: J26

• All other models: J27

• The pilot arc IGBT is

defective.

•Do Test 13 – Pilot arc IGBT on

page 125.

•The DSP PCB is

defective.

• Replace the DSP FSB.

The output from the

plasma power supply

is too low.

• The output current (A) is

set too low.

• Use the adjustment knob to increase

the output current (A) as necessary.

Problem Meaning Causes Solutions

Loading...

Loading...