ecification

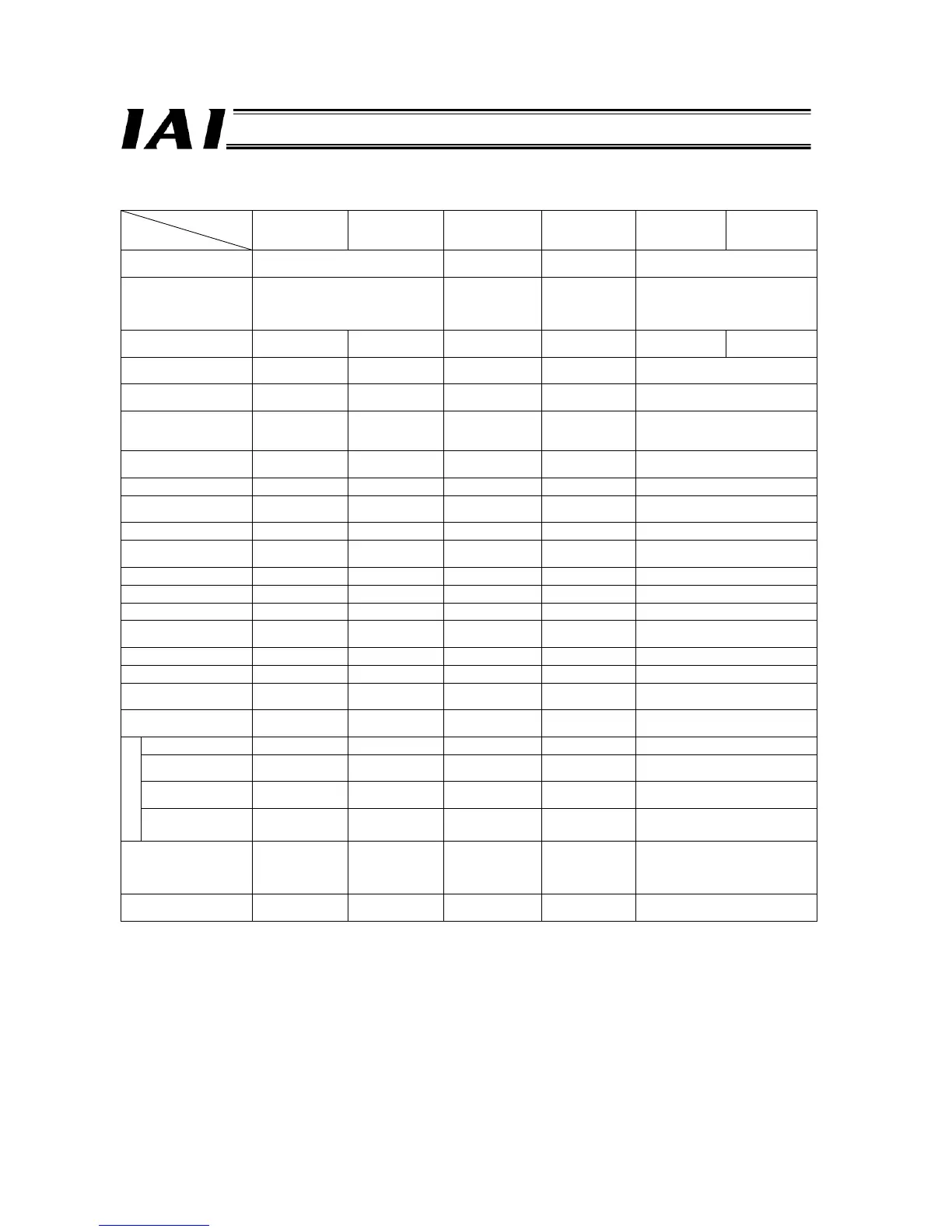

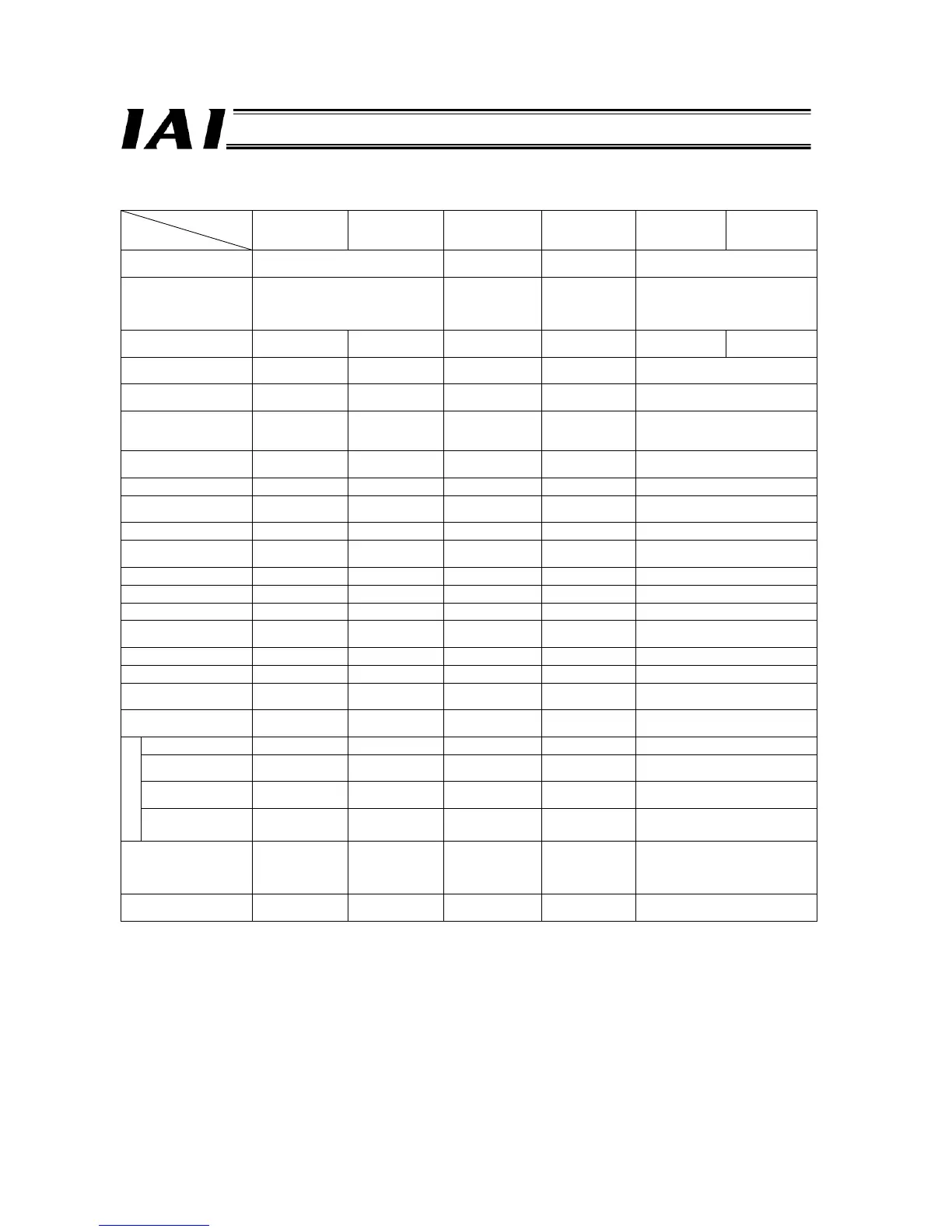

List of ROBONET Operation Functions

Operation mode

Item

Positioner 1

mode

Simple direct

mode

Direct numerical

specification

mode

Positioner 2

mode

Solenoid valve

mode 1

Solenoid valve

mode 2

Axis area

(Both input and output)

4 words 8 words 2 words 2 words

Fixed area

(Both input and output)

8 words

(The command area can be used.)

8 words

(The command

area cannot be

used.)

8 words

(The command

area can be

used.)

8 words

(The command area can be used.)

Number of registrable

positions

768 points/axis 768 points/axis - 768 points/axis 7 points/axis 3 points/axis

Operation by position

number specification

{ {

X

{ {

Direct position data

specification

X (Position table)

{ {

X (Position table) X (Position table)

Direct speed &

acceleration/deceleratio

n specification

X (Position table) X (Position table) { *3 X (Position table) X (Position table)

Direct positioning band

specification

X (Position table) X (Position table)

{

X (Position table) X (Position table)

Push operation { (Position table) { (Position table)

{

(Direct specification)

{ (Position table) { (Position table)

Completed position

number monitor

{ {

X

{ {

Zone output monitor

{ { { { {

Position zone output

monitor

{ {

X

{ {

Teaching operation

{

X X

{

X

Jogging operation

{ { { {

X

Inching operation

{ { { {

X

Various status signal

monitor *1

{ { { {

X

Current position monitor

*1

{ { { {

X

Alarm code monitor *1

{ { { {

X

Speed/electrical current

monitor *1

X X

{

X X

Axis monitor function in

AUTO mode *2

{ { { { {

Handshake

{ {

X

{ {

Position table data

read/write

{ {

X

{ {

Current position

read

X X X X X

Command

Broadcast

{

X X

{ {

Maximum specifiable

position data value

9999.99 mm

(When a

command

is used)

9999.99 mm 9999.99 mm

9999.99 mm

(When a

command

is used)

9999.99 mm

(When a command is used)

Number of connectable

axes

16 16 8 16 16

*1 Various status signals, current position, alarm codes and speed/electrical current can be monitored by accessing each

address of the gateway unit from the PLC.

*2 Before, axis monitor was not possible in the AUTO mode. This has become possible with the ROBONET, even when the

MODE switch is set to AUTO, by connecting a dedicated touch panel to the TP connector.

*3 Separate values cannot be set for acceleration and deceleration. The acceleration and deceleration are always the same.

Loading...

Loading...