ecification

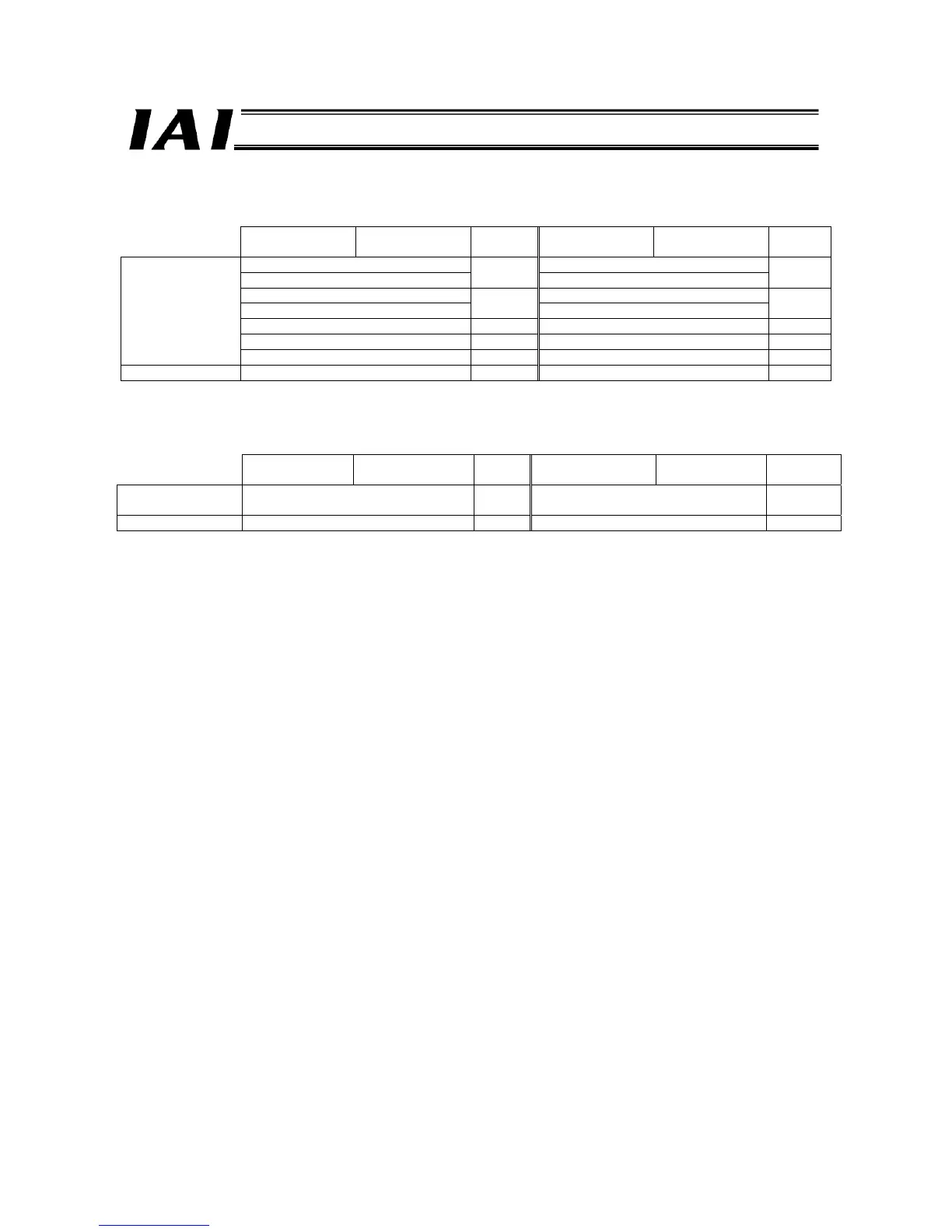

(3) Data Area Configuration in the Direct Numerical Specification Mode

PLC output ⇒ Axis input

Axis output ⇒ PLC input

Upper byte Lower byte

Number

of words

Upper byte Lower byte

Number

of words

Position data specification (L)* Current position data (L)*

Position data specification (H)*

2

Current position data (H)*

2

Positioning band specification (L)* Current electrical current (L)*

Positioning band specification (H)*

2

Current electrical current (H)*

2

Speed specification 1 Current speed data 1

Acceleration/deceleration specification 1 Cannot be used. 1

Direct numerical

specification area

Push-current limiting value 1 Alarm code 1

Control signal area Control signal 1 Status signal 1

* (L) indicates the lower word of 2-word data, while (H) indicates the upper word of 2-word data.

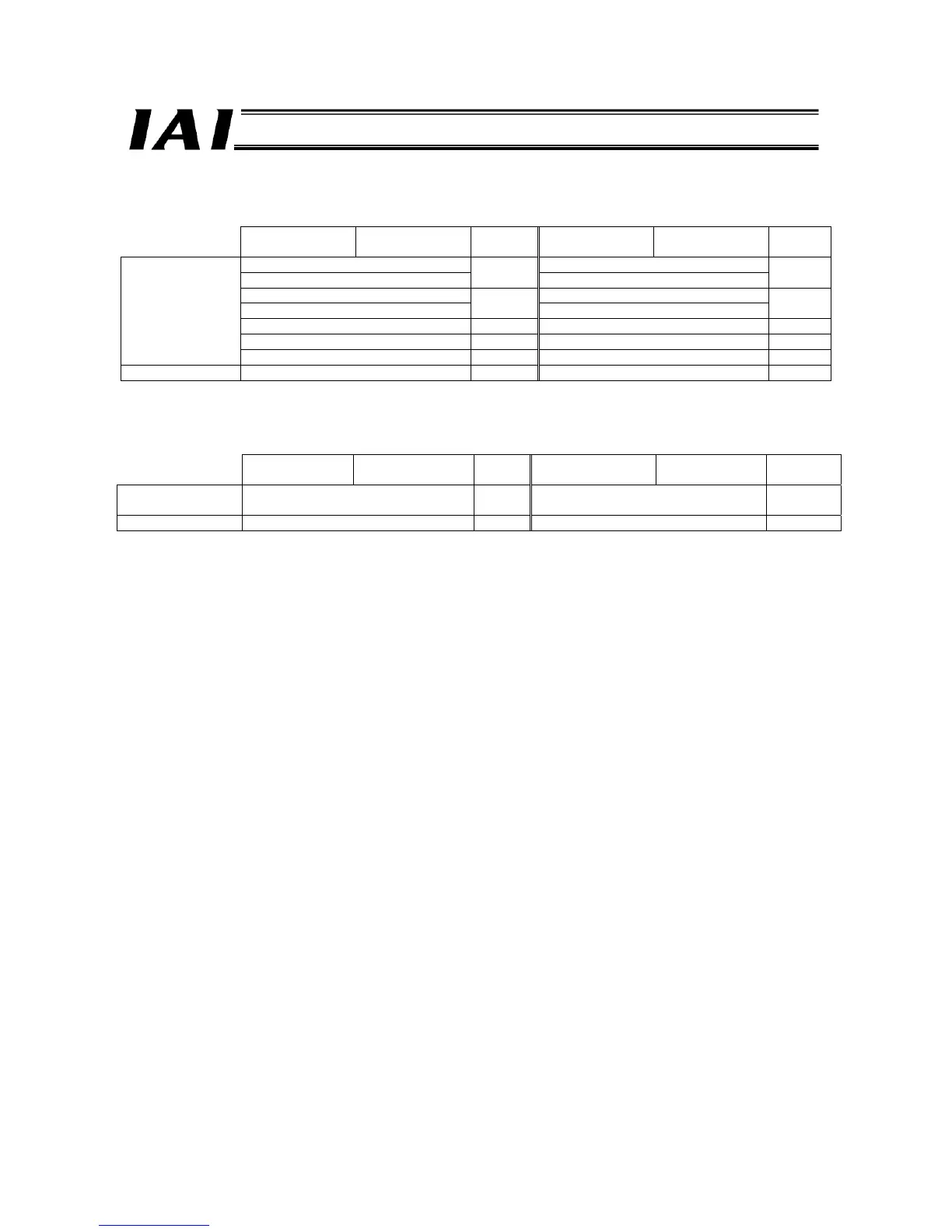

(4) Data Area Configuration in the Position 2 Mode, Solenoid valve mode 1 And Solenoid Valve 2 Mode

Upper byte Lower byte

Number

of words

Upper byte Lower byte

Number of

words

Position

specification area

Command position number

1

Completed position number

1

Control signal area Control signal 1 Status signal 1

3.7.1 Examples of Overall Address Configuration

Overall address configurations are shown based on a system where 12 4-word mode axes (positioner 1/simple direct mode)

and two 8-word mode axes (direct numerical specification mode) are connected.

For your information, the CC-Link and DeviceNet types use word addressing, while the PROFIBUS and RS485 SIO types use

byte addressing.

(1) CC-Link

A configuration example using the CC-Link type is shown on the next page.

The eight words in the fixed area are assigned to bit registers (RX/RY), while the area of each axis is assigned to word

registers (RWr/RWw).

Loading...

Loading...