353

Part 3 Maintenance

Code Alarm name Cause/action

0A2 Position data

error

Cause: [1] A movement command was input when a target position was not set in the

“Position” field.

[2] The target position in the “Position” field exceeds the specified soft limits.

Action: [1] Set a target position first.

[2] Change the target position to a value within the specified soft limits.

0A3 Position

command data

error

Cause: The speed or acceleration/deceleration in the numerical command exceeds the

maximum setting.

Action: Change the speed or acceleration/deceleration to an appropriate value.

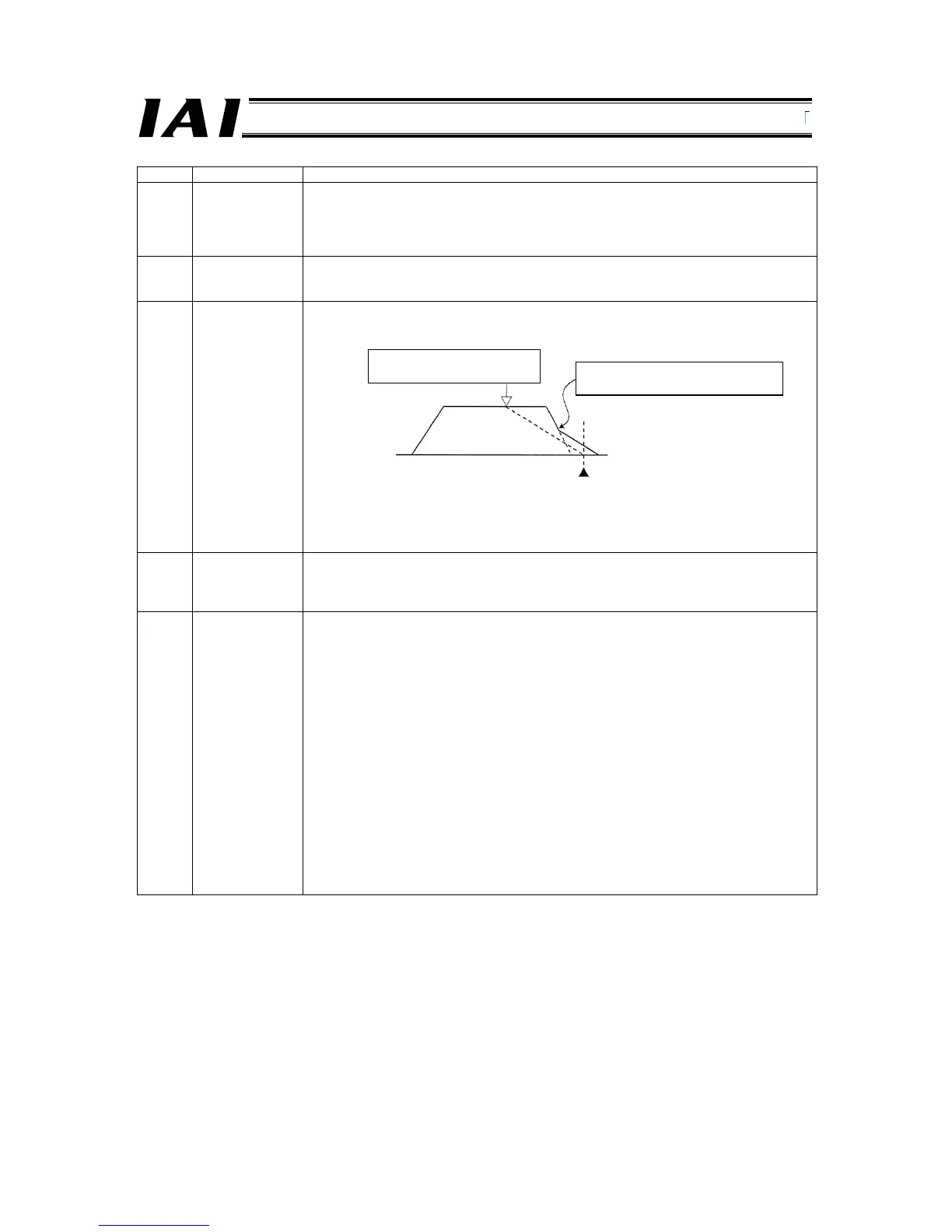

0A7 Command

deceleration error

When the target position is near a soft limit and the deceleration is set low, issuing a

command with the applicable position number while the actuator is moving may cause the

actuator to exceed the soft limit.

Cause: The next movement command was not issued quick enough after a speed

change implemented while the actuator was moving.

Action: Change the speed quickly so that the actuator will not overshoot by exceeding

the soft limit.

0B5 Z-Phase Position

Error

The position where the Z-phase is detected before the home return operation is out of the

specified range, or Z-phase is not detected.

Cause: Encoder Error

Action: Contact our company

0B6 Phase-Z

detection timeout

(RACON only)

This controller performs magnetic-pole phase detection (pole sensing) when the servo is

turned on for the first time after the power ON. This alarm indicates that the encoder

phase-Z signal could not be recognized within the specified time.

• When the detail code is H’0001:

Pole sensing operation + Magnetic pole check

• When the detail code is H’0002:

Operation after reversing upon push & hold action following a home return

Cause: [1] Loose or disconnected encoder-relay or motor-relay cable connector

[2] Brake cannot be released on an actuator equipped with brake.

[3] Large motor load due to application of external force

[4] Large slide resistance of the actuator itself

Action: [1] Check the wiring condition of the relay cables.

[2] Check the wiring condition of the brake cable. Also, turn on/off the brake

release switch and check if the brake makes “click” sounds.

[3] Check for abnormality in the assembly condition of mechanical parts.

[4] If the load is normal, cut off the power and move the actuator by hand to

check the slide resistance.

If the actuator itself is suspected, such as when a faulty encoder is a likely

cause, please contact IAI.

Deceleration starting position not

resulting in soft limit overshoot

If a command is issued at this position,

the soft limit will be exceeded.

Soft limit

Loading...

Loading...