ecification

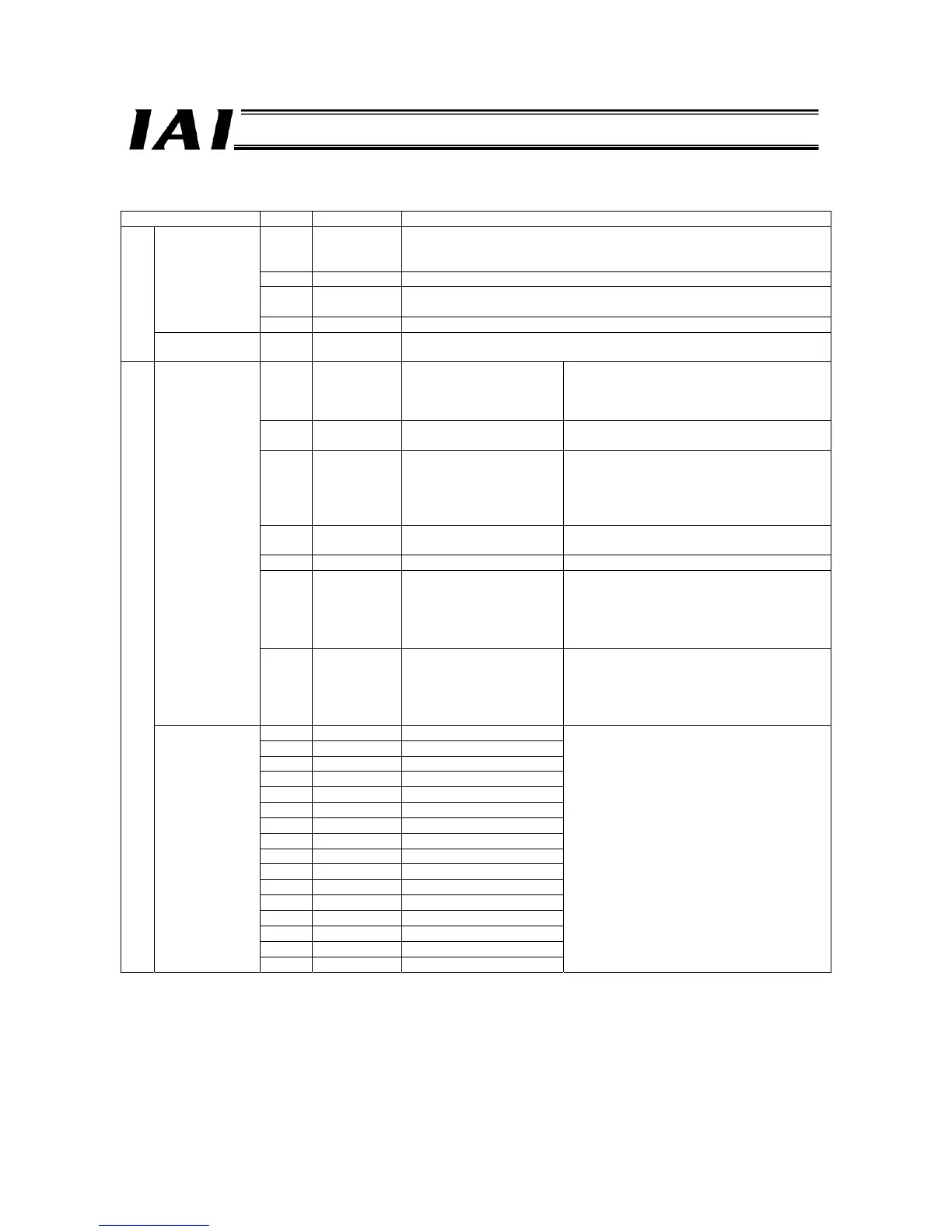

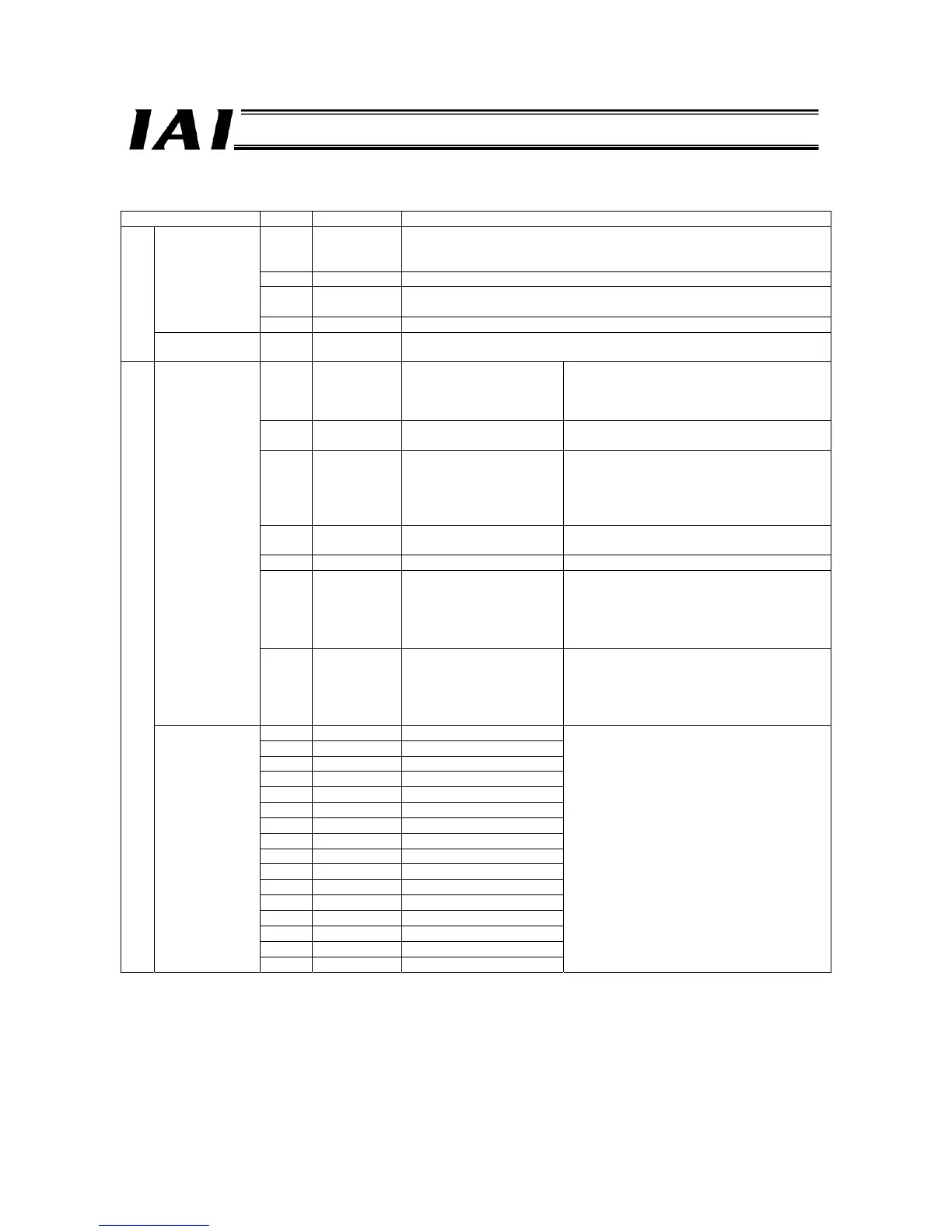

I/O Signal List

Signal type Bit Signal name Description

15 MON

When this signal is ON (“1”), control outputs from the PLC are effective

(outputs from the PLC are reflected in the controller unit). When the signal

is OFF (“0”), the outputs are ineffective.

14 - Cannot be used. Always keep this signal OFF (0).

13 RTE

When ERR-T or ERR-C is occurred, it can be cancelled by setting this bit

to 1 (level input) from the current condition.

Control signal 0

12-0 - Cannot be used. Always keep this signal OFF (0).

PLC output

Control signal 1 15-0 - Cannot be used.

15 RUN

Gateway unit operation

normal output

This signal is ON while the gateway unit is

operating normally. The signal is

synchronized with the LED (RUN) on the front

panel of the unit.

14 LERC -

If ERR-C occurs, the current condition is

maintained.

13 ERRT

ROBONET communication

error output

This signal turns ON upon detection of a

ROBONET communication (SIO

communication) error. The signal is

synchronized with the ERROR-T LED on the

front panel of the unit.

12 MOD MODE switch output

This signal is ON when the MODE switch on

the front panel of the unit is set to MANU.

11-10 - - Cannot be used.

9 W8B16

8 W8B8

7 W8B4

6 W8B2

5 W8B1

Number-of-axes setting in

direct numerical

specification mode

The number of axes in the direct numerical

specification mode is output as a 5-bit binary

code.

4 W4B16

3 W4B8

2 W4B4

1 W4B2

Status signal 0

0 W4B1

Positioner mode or simple

direct mode

The number of axes in the positioner mode or

simple direct mode is output as a 5-bit binary

code.

15 LNK15 Linked axis No. 15

14 LNK14 14

13 LNK13 13

12 LNK12 12

11 LNK11 11

10 LNK10 10

9 LNK9 9

8 LNK8 8

7 LNK7 7

6 LNK6 6

5 LNK5 5

4 LNK4 4

3 LNK3 3

2 LNK2 2

1 LNK1 1

PLC input

Status signal 1

0 LNK0 0

The signal of each linked axis turns ON (“1”).

Loading...

Loading...