Model 250

Printer Applicator

Operators/Technical Manual Section Three

Section 3 Page 2 of 19

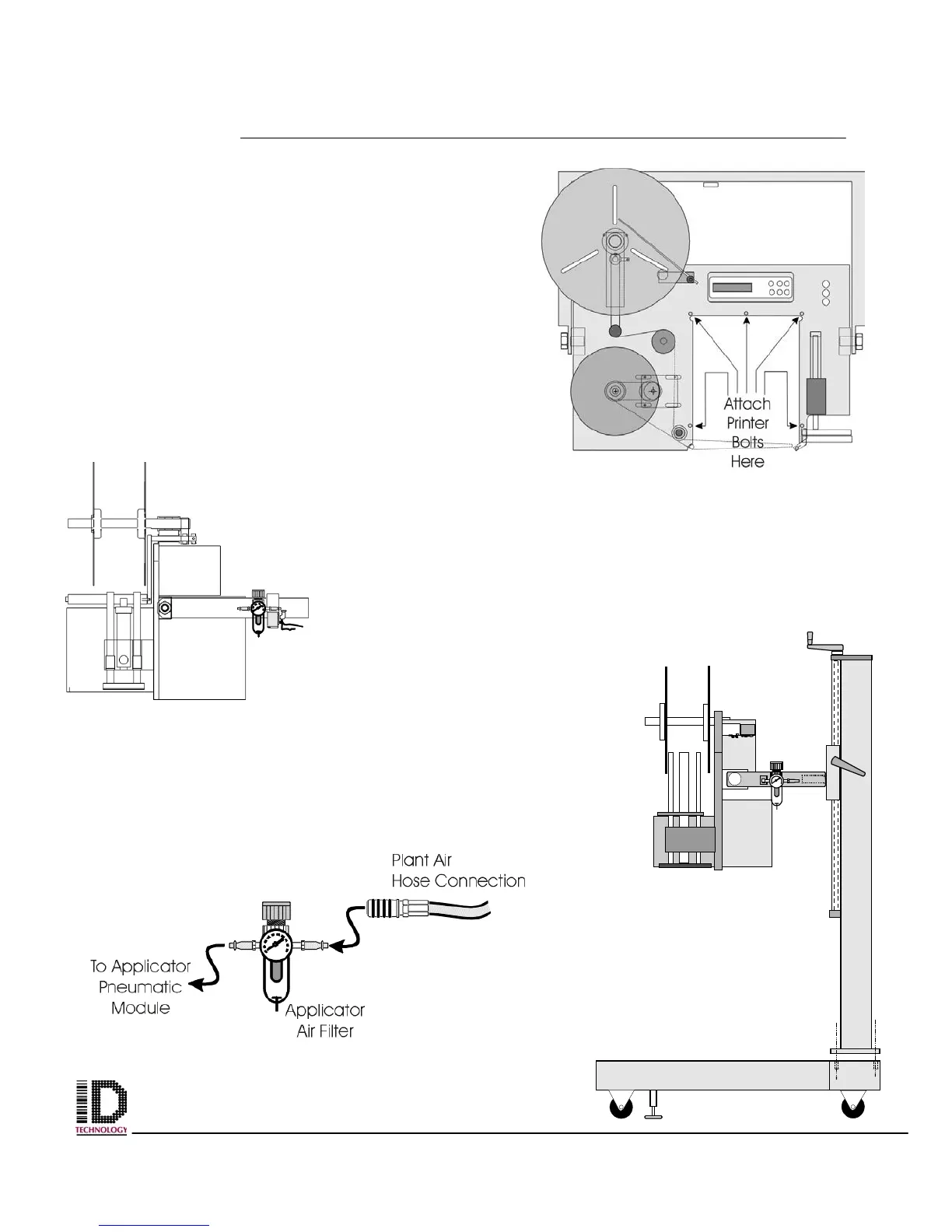

Figure 3-4 Print engine mounting

hole placement on faceplate.

If your OEM print engine came in a separate

carton from the applicator:

Locate the print engine, remove the packing and

carefully take engine out of carton. Locate the five

bolts that mount the engine to the faceplate. If

they are in the faceplate remove them and set

aside. Slide the engine into the area on the

faceplate and align the mounting holes on the

engine with those on the faceplate. Start each bolt

by hand and ensure all five line up and engage

without cross threading. Once all bolts have been

started, using a 4 mm Allen wrench tighten

securely.

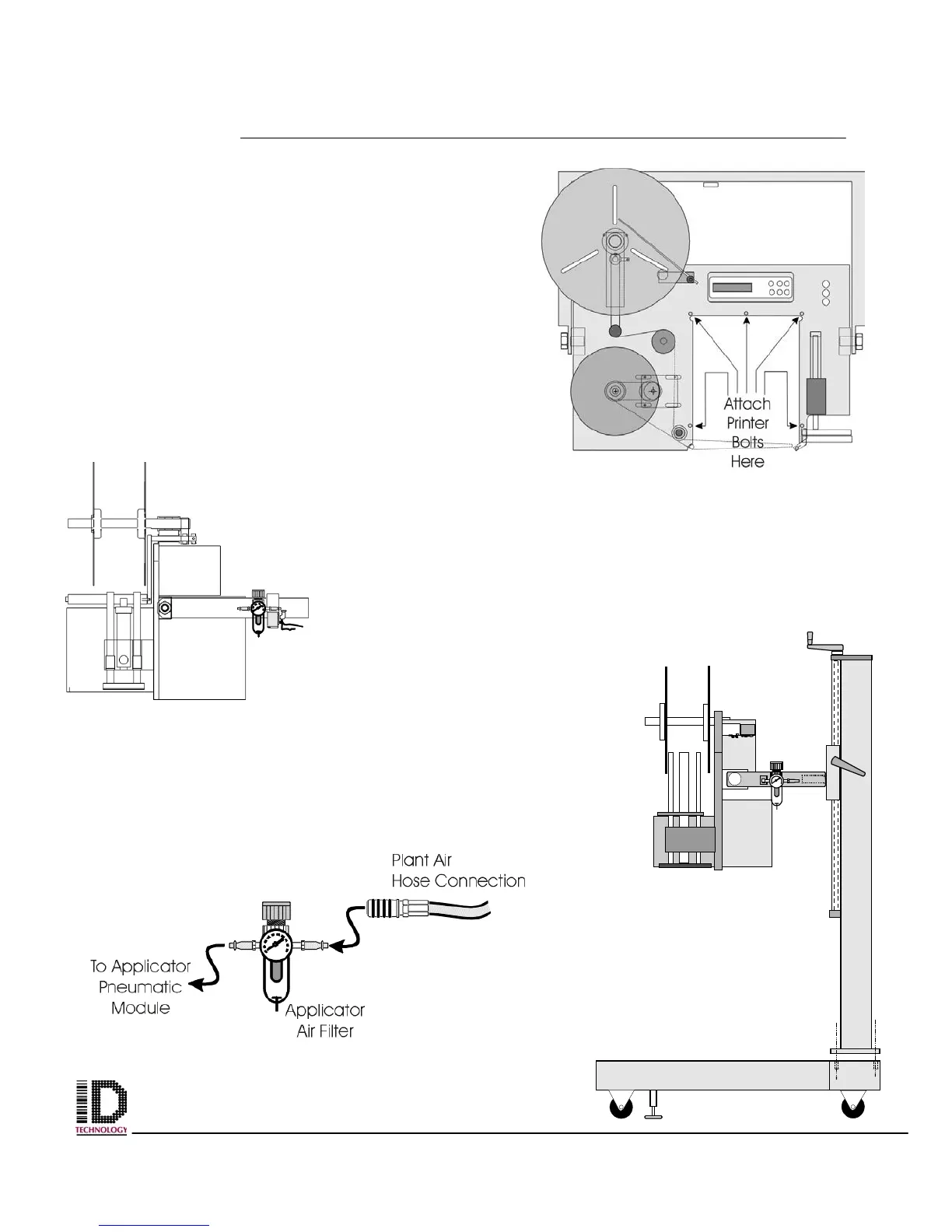

Locate the plant air

hose connection. The

applicator requires

clean dry air at 80 psi to 120 psi. A pre filter upstream of the

applicator will reduce required preventive maintenance on the

system. The connector should be a ¼ NPT. Connect to the

applicator Air Filter located on the u-arm. (See figure 3-5).

Connect the plant air hose to

the input of the air filter. The

output of the air filter will be

connected to the pneumatic

manifold block on the

pneumatics module mounted

on the back of the applicator

faceplate.

End View

Tamp Down

Orientation

Figure 3-5 Air Filter

placement on U-arm and

Loading...

Loading...