Model 250

Printer Applicator

Operators/Technical Manual Section Four

Section 4 Page 4 of 6

The Label is fed toward the tamp pad as it exits the print engine. The liner is driven

around the peel tip of the printer. While the label dispenses off of the liner, it dives down

due to the angle at which it is dispensed, the close proximity of the tamp pad, and gravity.

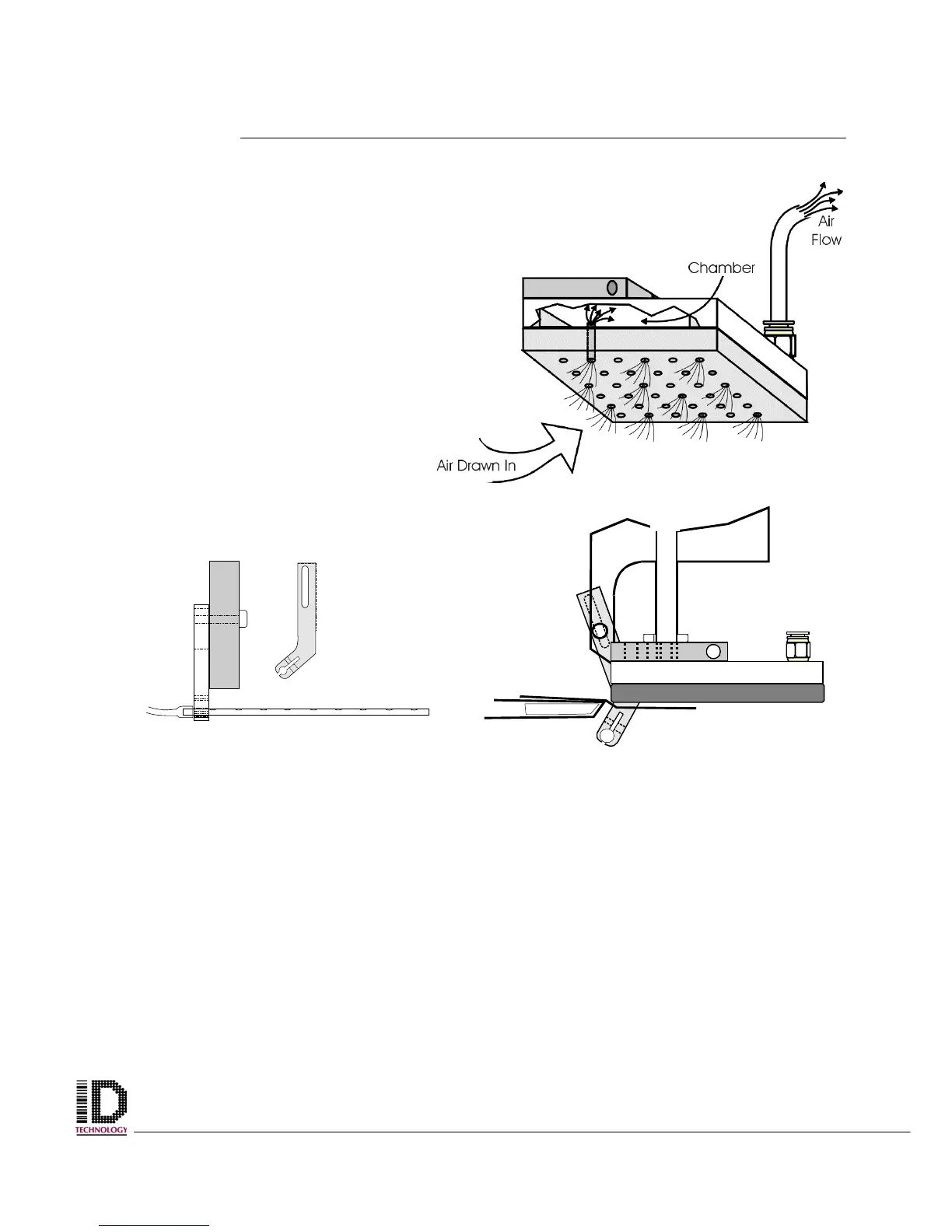

An air assist tube is mounted slightly below the print engine (figure 4-7 and 4-8).

This fluted metal tube directs an airflow towards the tamp pads surface and as the label

crosses in front of the tube, it is blown back towards the tamp pad. This assists the label

in staying flat against the tamp pad as it is fed from the printer, until the vacuum of the

tamp takes control. Air assist is energized at a specific time (operator adjustable) after

the label has commenced feeding. Energizing the air assist to soon or too late can result

in poor label dispense, label placement on the tamp pad, and label placement accuracy

on the product.

Figure 4-7 Air Assist tube

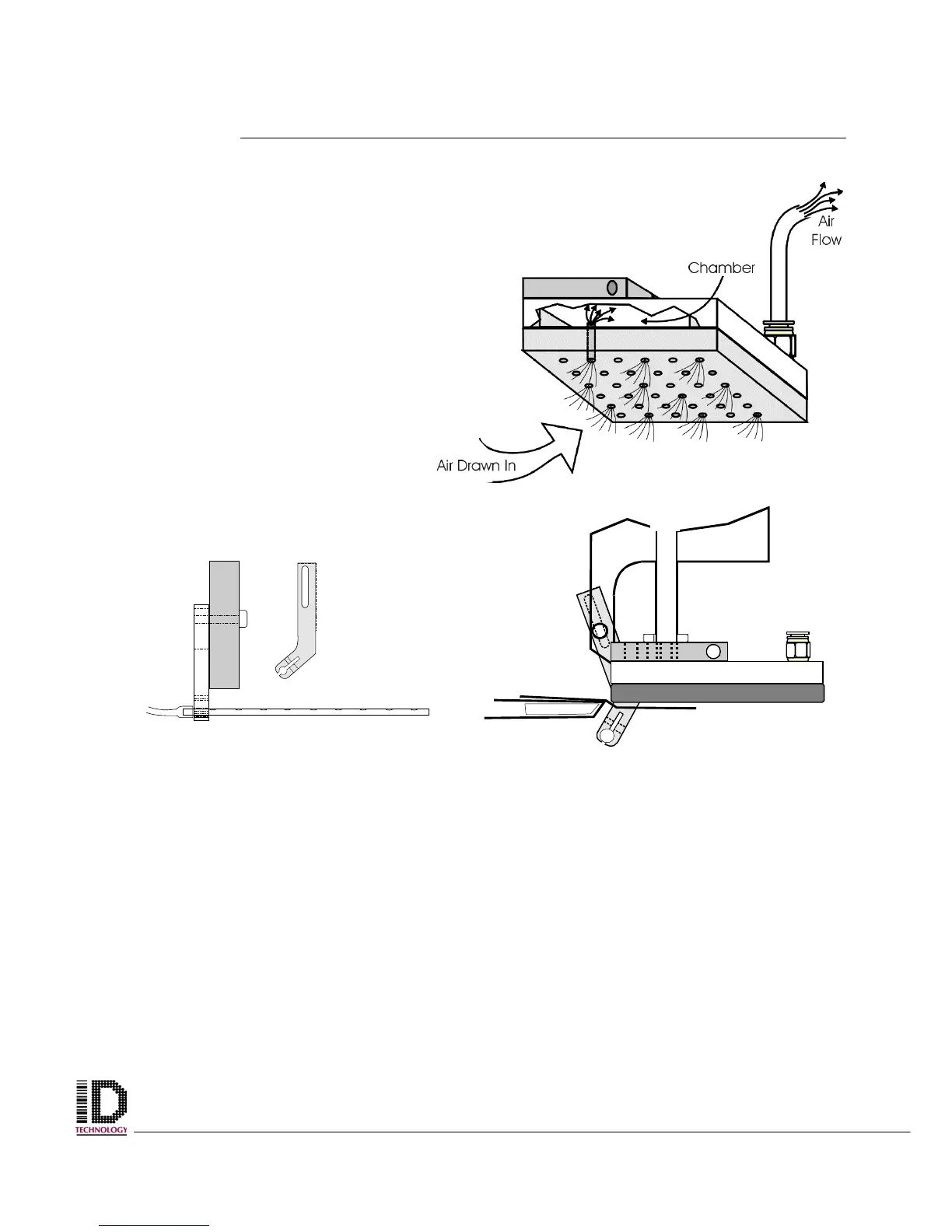

Figure 4-6 Flow of air through

tamp pad creating a vacuum. This

results from the Venturi effect.

Figure 4-8 Peel Tip feeding a label

Loading...

Loading...