Model 250

Printer Applicator

Operators/Technical Manual Section Three

Section 3 Page 11 of 19

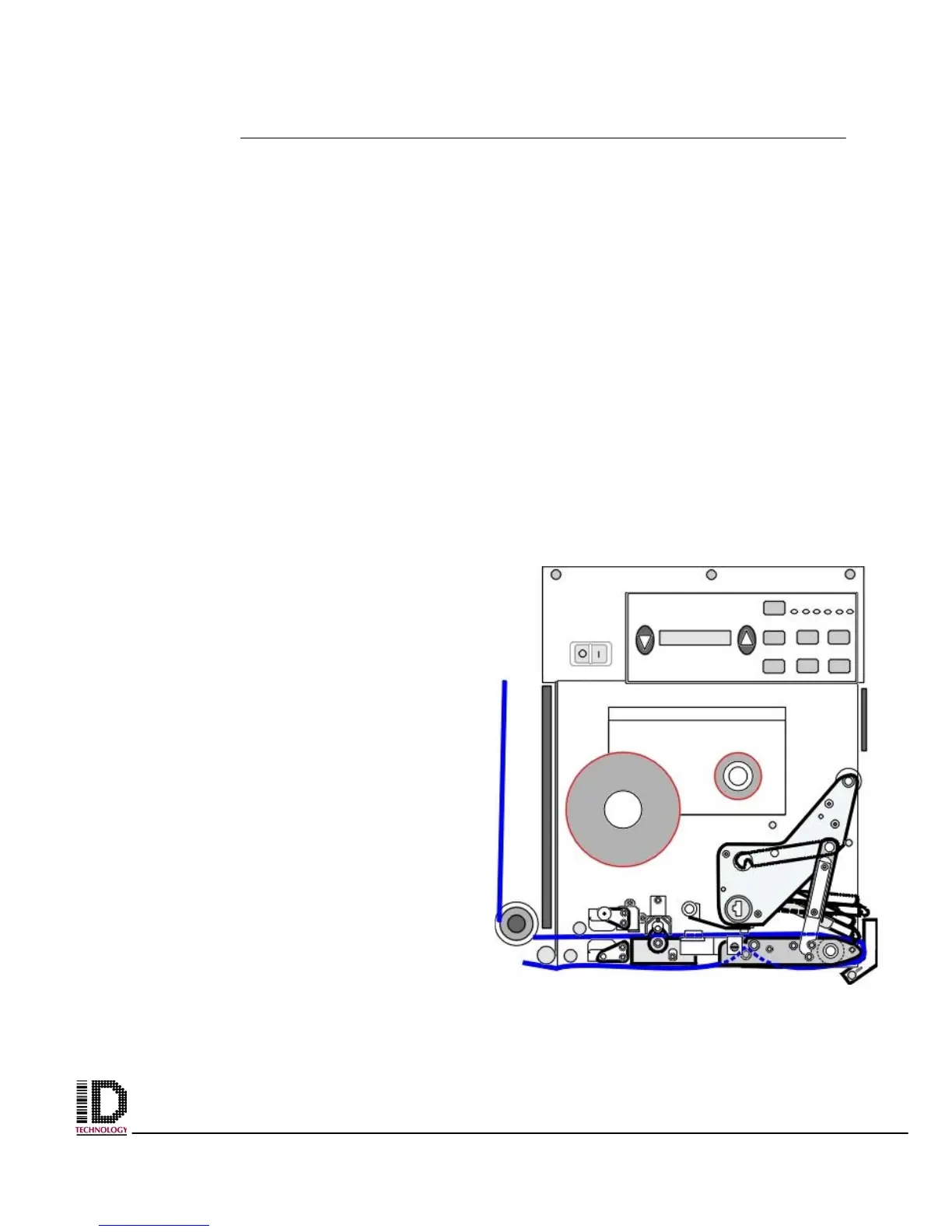

To Load Labels through the Zebra Printer Engine

(refer to Figures 3-16 and 3-17 with the following procedure)

1. Grasp the thumbnut (A) and slide the outer media edge guide (B) as far out

from the printer frame as possible. (The thumbnut does not have to be

loosened.)

2. Open the printhead assembly (C) by unlatching the printhead lock lever (D)

from the locking pin (E).

3. Raise the pinch roller (F) by pressing down on the pinch roller assembly latch

(G). Thread the media under the upper guide post (H), between the pinch roller

and the associated rubber pinch roller, and under the printhead assembly (C)

until approximately 30” (75cm) of media extends out of the print engine.

4. Ensure the media is aligned within the print path then close the printhead

assembly (C) by rotating the printhead lock lever (D) until it latches onto the

locking pin (E).

5. Secure the pinch roller (F) in position by pressing down on the top of the pinch

roller latch (G) until the assembly snaps closed.

6. Position the outer media edge

guide (B) so it just touches the

outer edge of the media.

7. Raise the peel roller latch (I) and

the peel roller assembly (J) will

pivot down to a vertical position.

8. Thread the backing material

around the peel bar (K), under the

platen roller (L), and through the

peel roller assembly (J). (see

Detail in figure 3-17.)

9. Ensure you route the media

between the air assist tube and

the print engine frame. (DO NOT

thread the media over the air

assist tube.)

10. Rotate the peel roller assembly

(J) up until it latches closed.

11. Thread the backing material

under the lower guidepost (M)

and around the take-up spindle

of the applicator.

Figure 3-18 Front view of label web threaded

through Zebra engine

Loading...

Loading...