Model 250

Printer Applicator

Operators/Technical Manual Section Three

Section 3 Page 8 of 19

Label Threading (ZEBRA)

Threading Labels through the applicator can be accomplished in under 30 seconds once

you have loaded labels a few times and got the hang of it. The roll of labels you use

should be stored in a cool dry climate.

Humidity and heat can ruin the roll of labels

and cause many problems during printing and

application. Labels kept in a hot and or humid

environment tend to bleed. That is, the

adhesive begins to soften and seep out the

sides. This causes labels to stick together or

not separate from the liner. The labels won’t

dispense onto the tamp pad or curl around the

peel tip and flounder on the air assist tube.

First remove the outer flange of the unwind.

The inner flange should be mounted with the

hub facing out, or towards you. Slide the

labels (Wound out on a 3” core) over the

unwind shaft and onto the 3” diameter hub of

the inner flange. Ensure the core is snug on

the hub and flush with the back flange. Re-

install the outer flange with the flat of the

shafted lined up with the flat of the decal on

the outer hub. Once you have the outer flange on, twist flange a

quarter turn in either direction to tighten onto shaft. There is a

setscrew through the hub that can be adjusted to give more or

less pressure against the shaft (4mm Allen wrench is required).

The label roll should not rotate easily at this point. To allow for

freewheeling of the unwind, move the dancer arm toward the

center of the machine. (refer to section one figure one part

identified as #16) This releases tension on the brake and will

allow you to unwind labels from the roll. About 3 feet is required

to complete the threading. Take the labels to the outside of the

dancer arm, around the bottom and over the roller to the right of

the dancer roller. (see figure 3-10)

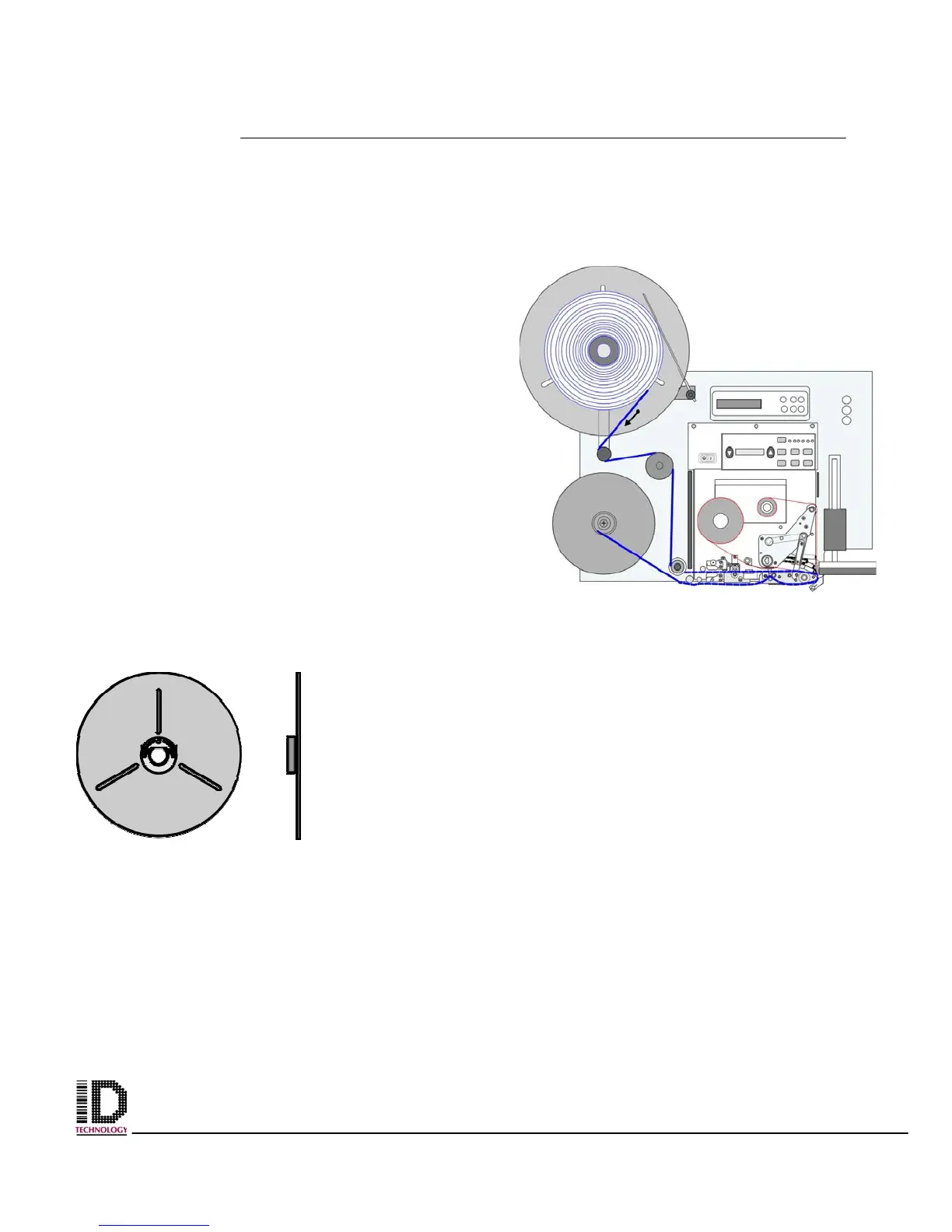

The web should now be hanging vertical to the floor or parallel to the print engine. As you

are facing the applicator the web will go around the left side of the roller directly to the left

of the print engine and about an inch from the bottom of the faceplate. The web should

now be heading to the right and into the print engine itself. Referring to the applicable

printer manual for more concise directions is advised. Figures 3-14 and 3-15 shows an

example of a Zebra print engine with the label threaded through.

Figure 3-14 Web Path through the applicator

and Printer

Figure 3-15 Outer

Flange with Hub Decal in

center

Loading...

Loading...