Model 250

Printer Applicator

Operators/Technical Manual Section Three

Section 3 Page 7 of 19

widths of media that can be used. (Please refer to the print engine manual for an

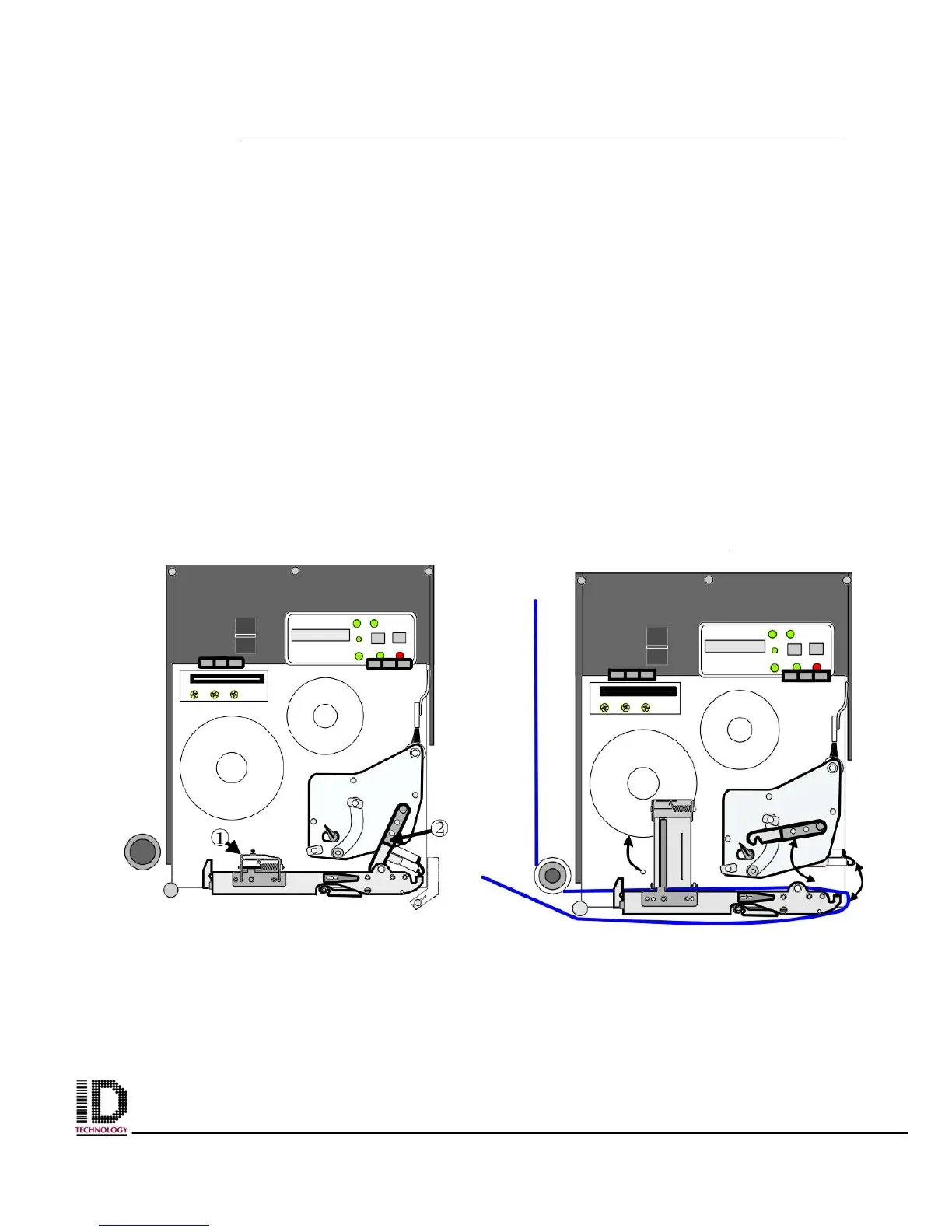

explanation on adjusting these guides.) In figure 3-12 the item marked as #1 is a spring

loaded bar that holds the web flat. It is equipped with a roller for reducing pull. You must

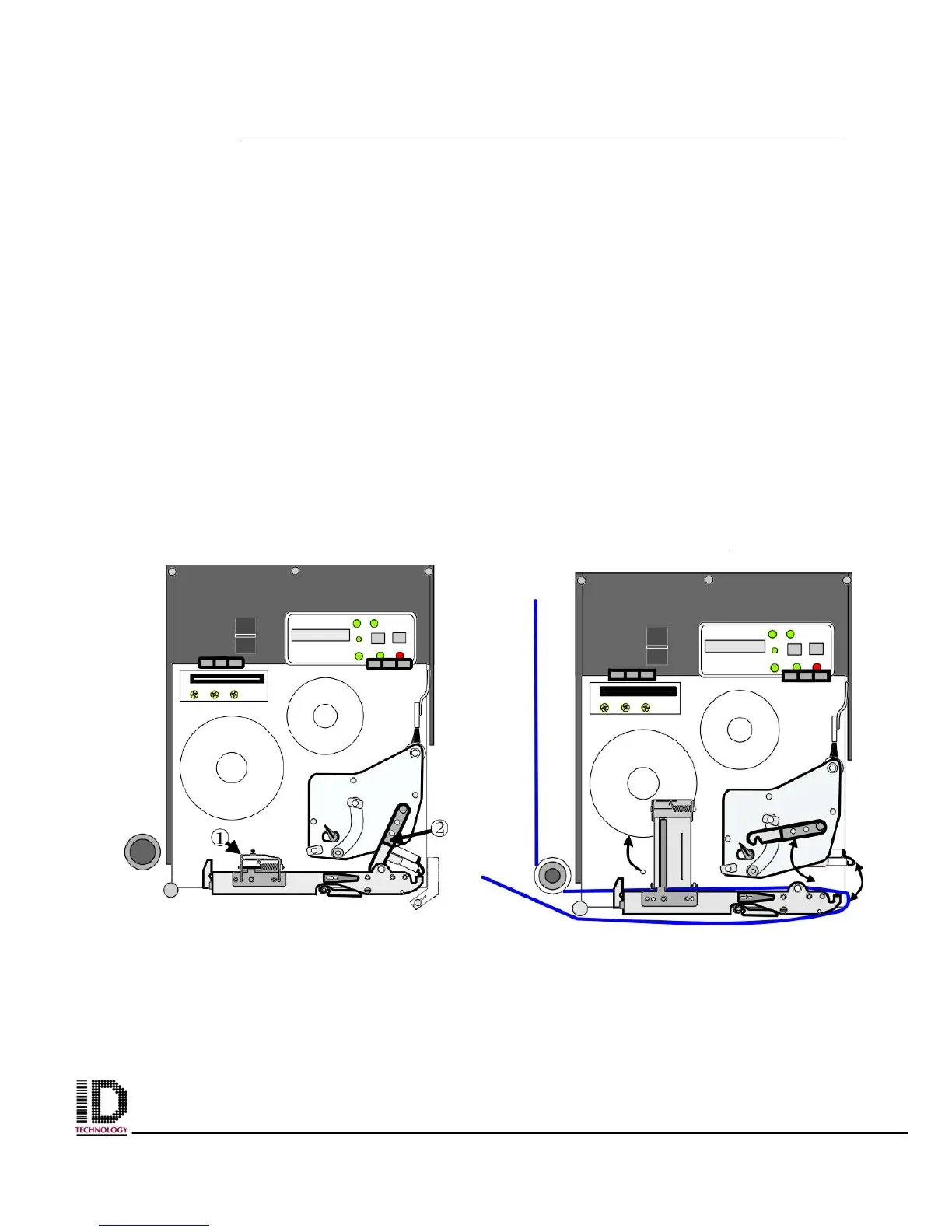

disengage this mechanism to thread the web. Figure 3-13 shows the mechanism

unlatched and in the raised or open position. (Please refer to the print engine manual for

a better explanation on how to unlatch this mechanism.) Item marked as #2, in figure 3-

12, is a lever that can be shifted to the left. Shifting this lever causes the print head to

spring up. The web must be threaded under the print head, out the far right side of the

engine and back under to the left. Figure 3-13 shows the print head in the “up” or “open”

position. (Referring to the print engines operator’s manual will give a clear understanding

of the operation and procedures for moving, adjusting, and locking the print head.)

It will be a lot easier to thread the liner if you remove the label from the web prior to

threading over the air assist tube. When bringing the web back under the print engine

ensure that the liner is above the air assist tube. (Liner should be between the air assist

tube and print engine.) Take the web to the rewind spindle, remove the locking pin, and

wrap the liner clockwise around the shaft. Reinstall the locking pin onto the shaft catching

the liner between the tines and the shaft.

Figure 3-12 Print Engine with door

removed for clarity.

Figure 3-13 Print Engine with label

web shown threaded

.

Loading...

Loading...