Model 250

Printer Applicator

Operators/Technical Manual Section Five

Section 5 Page 8 of 18

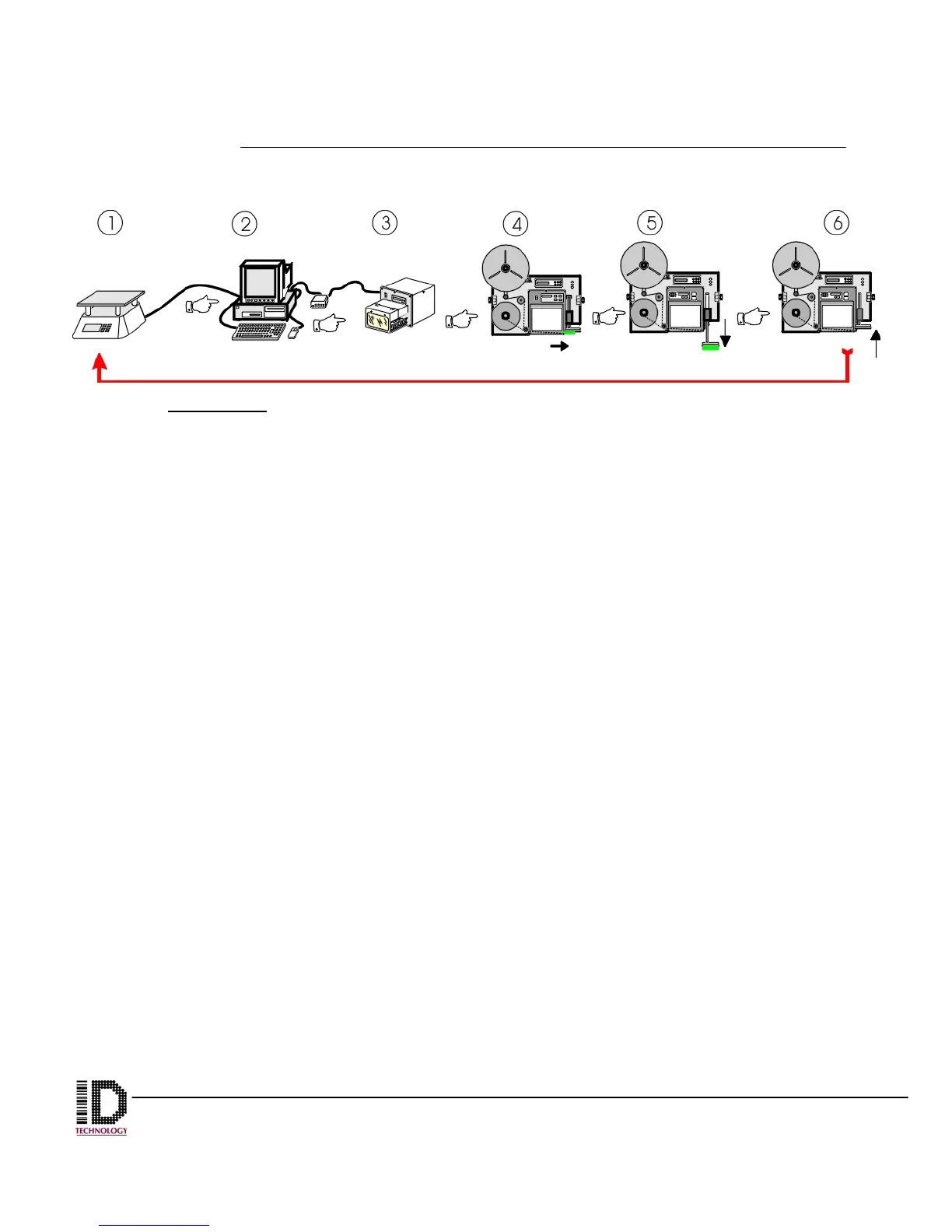

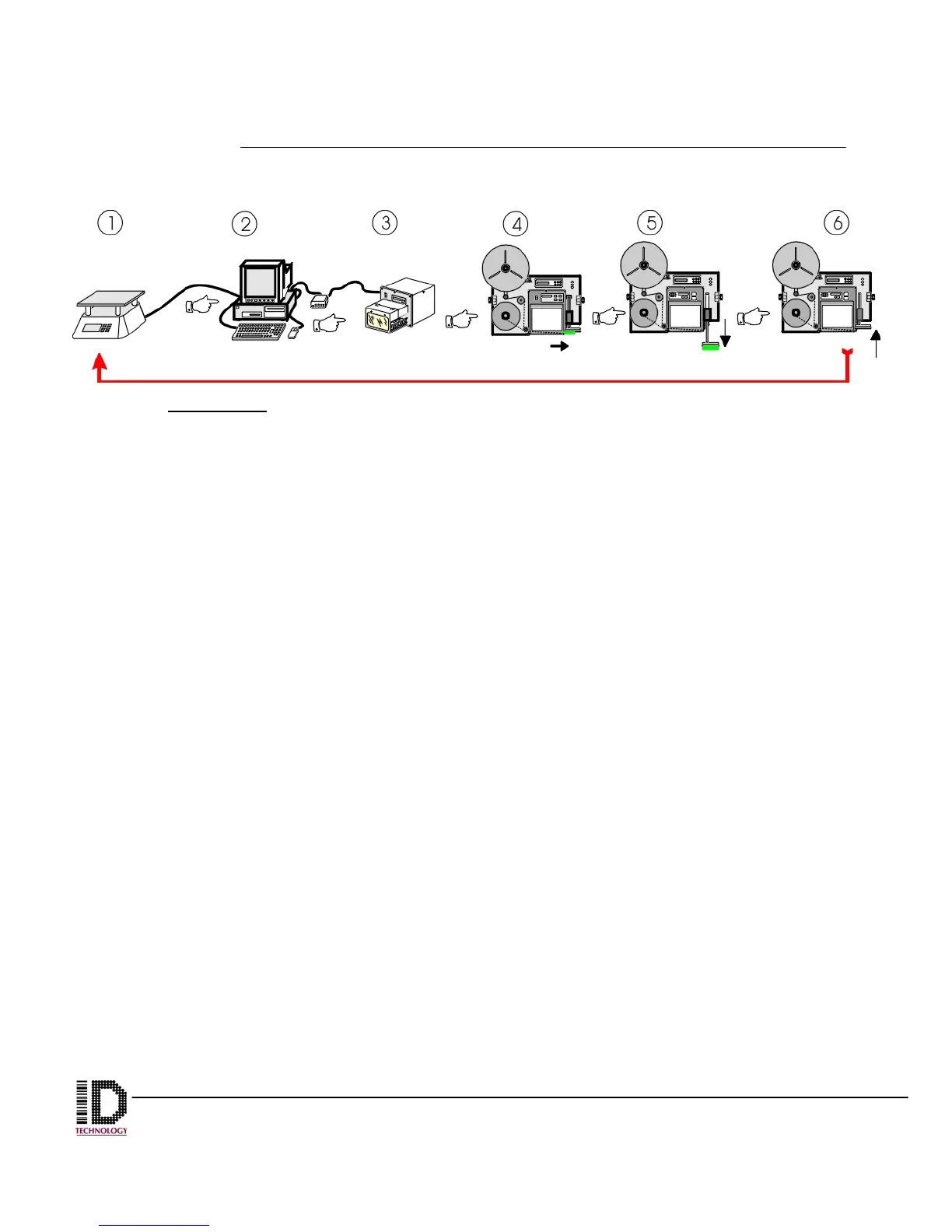

Figure 5-3 Data Driven Print Sequence.

3. Data Driven - If you select the Data Driven mode under the Print Sequence menu,

the system will be controlled by another system and typically used with a PLC.

Data is downloaded to print engine buffer and is printed only when given

information from another upstream system. (i.e.: a weight scale or a bar code

scanned on the side of the product.) When the upstream system senses the

product, and conveys the data to the print engine, a label is then printed and

dispensed. As soon as the label is completely dispensed onto the tamp pad or

blow on grid the application is accomplished (tamp, blow -on, etc…) At the end of

the application cycle the printer awaits another trigger from the upstream system

to start the process over. This continues until the upstream system is deactivated

or shuts down or there is an out of media signal from the applicator. As the label is

dispensed from the print engine, the air assist will turn on. At the end of the

dispense cycle, the air assist will de-energize. While the dispense cycle is on the

rewind cycle is on.

1. Operator generates a label format on the PC and loads the format to the

print engine.

2. Operator sets up the PLC and up stream system to control the labeling

system.

3. Up stream system senses product, conveys information or data to the

print engine and triggers print engine to print and dispense a label.

4. Label is printed and dispensed.

5. Cylinder extends (or blow on pneumatics are initiated) and Label is

applied.

6. Cylinder retracts (or blow on pneumatics is de-energized)

7. Engine awaits information/data from the upstream system.

Cycle starts back at the up stream system and continue until no more data

is generated or sent.

Loading...

Loading...