EN

4 - HANDLING AND INSTALLATION BOSS 332/545/552 HD

4 - Pag. 14 / 32

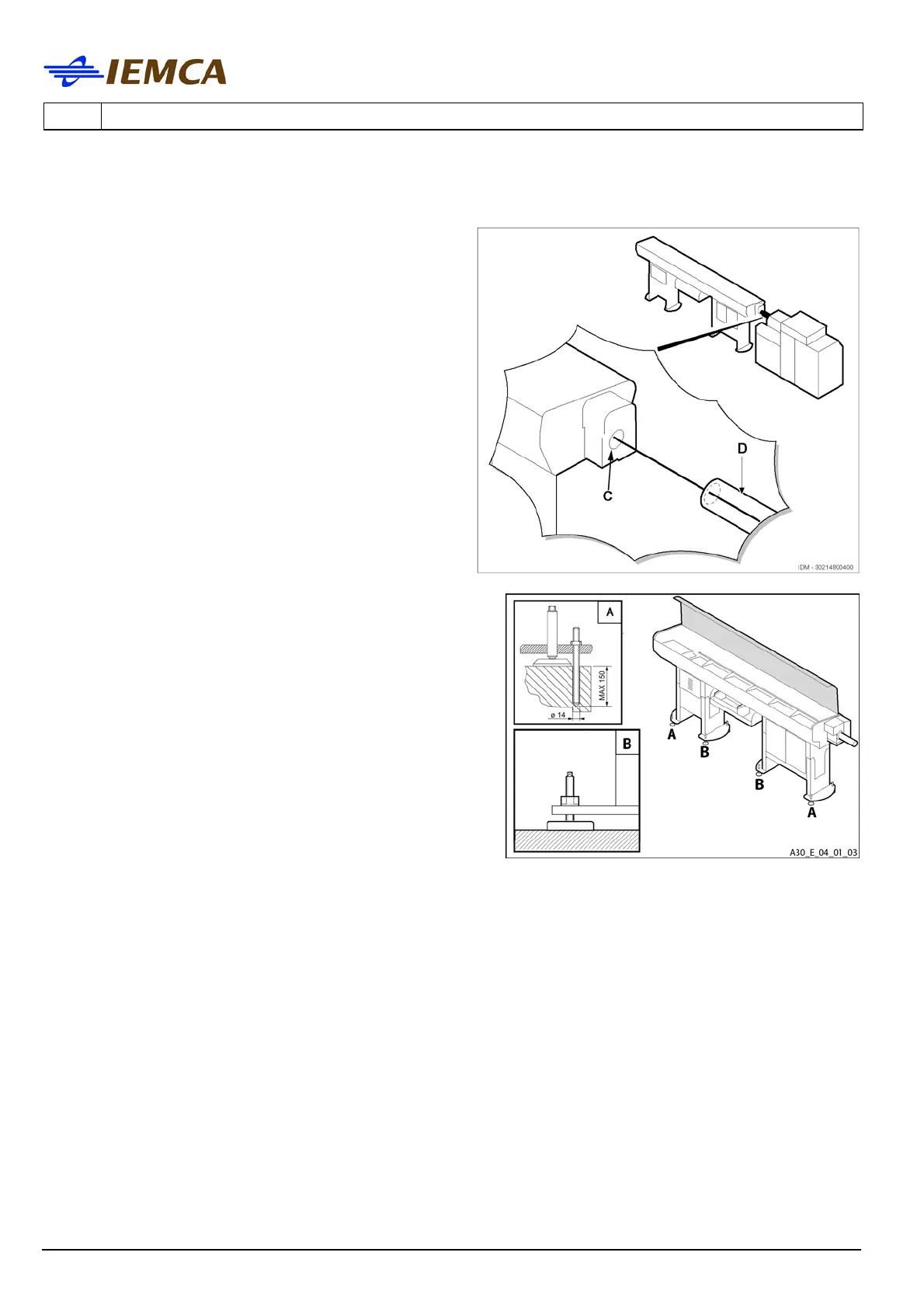

• use a sliding caliper to check alignment near

the sleeve "C" and the spindle "D"; adopt a

tolerance of 0.15 mm in all four directions.

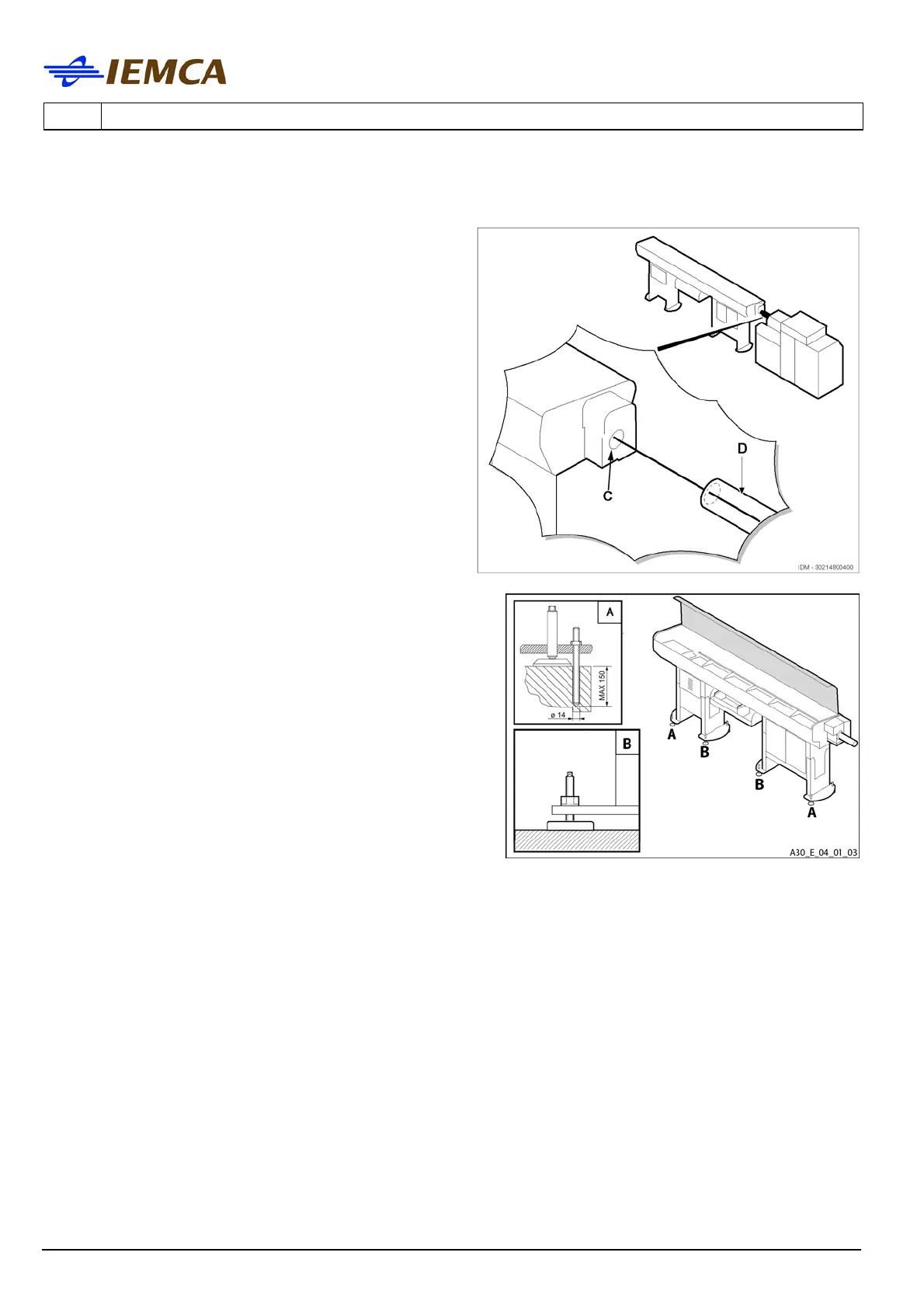

• prepare a perfectly straight ground bar, with

an external diameter equal to the maximum

spindle bar passage and with a length equal to

the double coupling distance (see "B" in

section 4.4.3);

• place the bar in the guide channel and make it

slide forwards and backwards in the spindle,

until almost reaching the lathe collet area.

POSITIONING ADJUSTMENTS

After checking the alignment of the bar feeder with

either the thread or the bar, any required corrections

should be carried out.

Adjust the height by turning the screws of the feet;

carry out the lateral adjustments with calibrated

mallet blows on the bar feeder foot.

During this phase, any adjustment carried out during

the levelling phase should be preserved; therefore,

in most cases, it is necessary to find the correct

adjustment of the bar feeder position.

Loading...

Loading...