The speed method can only be used on reciprocating compressors equipped with VSD and

the soft Centa coupling. It is not recommended for reciprocating compressors equipped with

the standard Rexnord coupling as it may lead to torsional vibration problems.

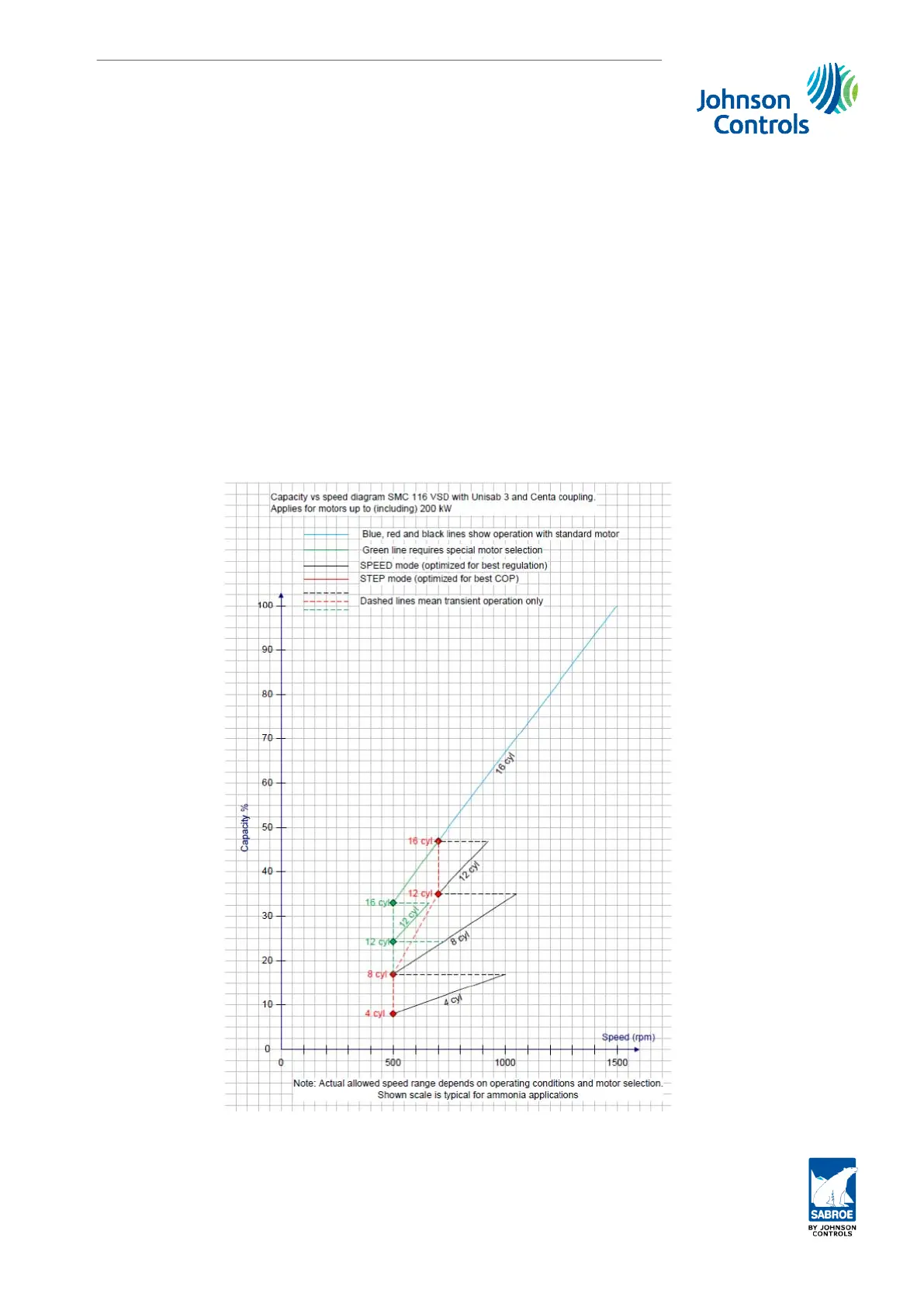

It works this way: The compressor starts with the first step engaged at low speed then it

ramps up to minimum speed, i.e. 500 [rpm]. At the first capacity step, it ramps up speed un-

til the capacity corresponds to the second step at minimum speed. Then the second step is

engaged and at the same time speed is ramped down to minimum. It will then ramp up

speed, engage the next step, slow down and so on until all steps are engaged at minimum

speed. Then speed is ramped up to maximum speed.

But notice that when more than half of the steps are engaged, a higher minimum speed 2 i.e.

700 [rpm] can be used. Unless a special motor is selected this higher minimum speed is nec-

essary to maintain proper motor fan cooling at a higher step load than 50%.

For SMC types and a standard setting where minimum speed is set to 500 [rpm], motor rpm

min. 2 is set to 700 [rpm] and maximum speed is 1500 [rpm], the reciprocating compressor

will be step/speed regulated up to 47% and then speed regulated between 47% and 100%.

Fig. 18: Capacity vs. speed curves for SMC 116 with Centa coupling

For CMO types and a standard setting where minimum speed is set to 700 [rpm], motor rpm

min. 2 is set to 900 [rpm] and maximum speed is 1800 [rpm], the reciprocating compressor

will be step/speed regulated up to 50% and then speed regulated between 50% and 100%.

Compressor control and surveillance

Engineering manual - Unisab III 1.10

001930 en 2014.09

119/319

Loading...

Loading...