55

LeeBoy 6150 Conveyor Paver 5-13

Maintenance

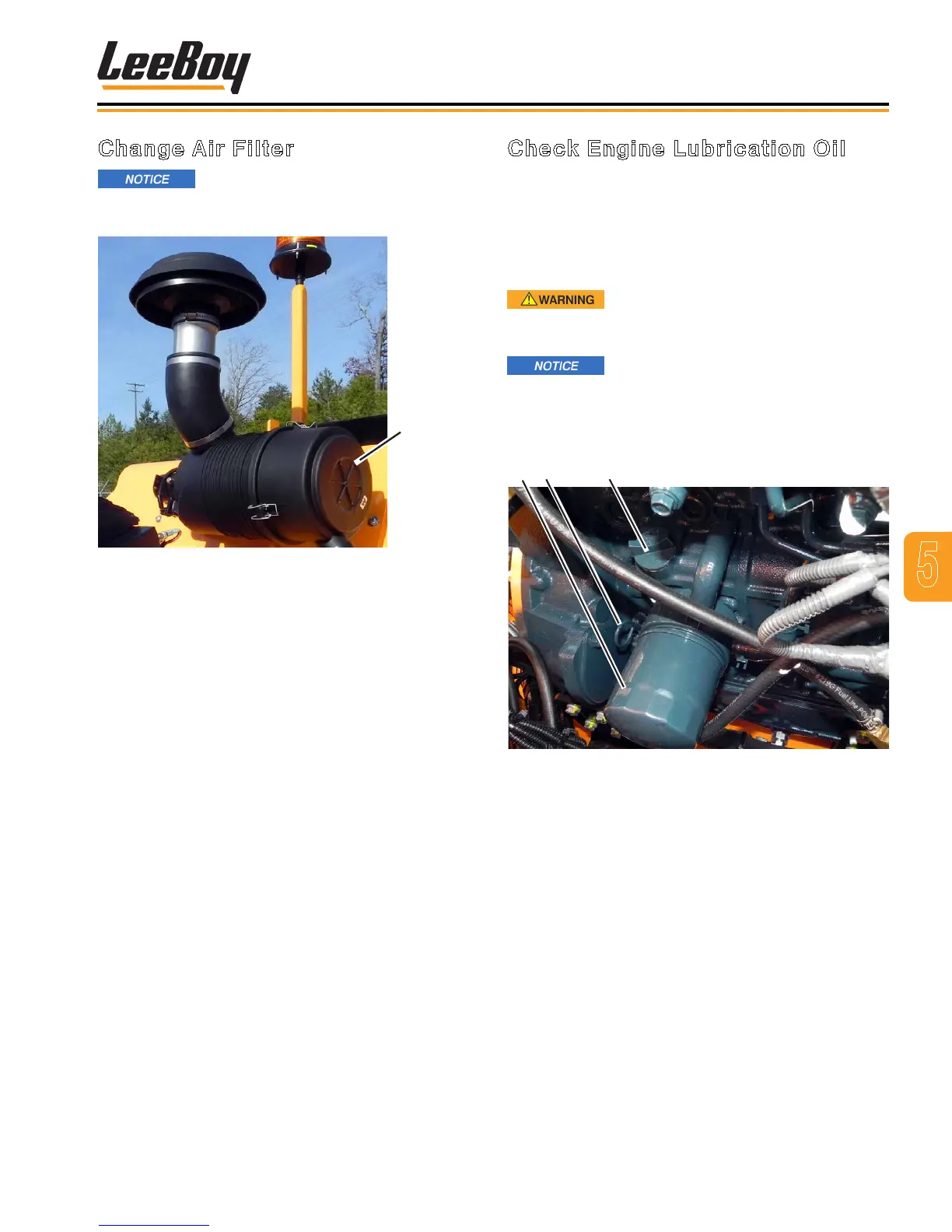

Check Engine Lubrication Oil

The engine lubrication oil must be kept at a level above

the ADD mark, but not above the FULL mark, on the

engine lubrication oil dipstick. Access the oil and

lter and dipstick via the hopper engine access door.

(Figure 5-11) The engine oil ller cap can also be

accessed via the top access panel.

DO NOT check the oil while the

engine running. Hot oil can spew and cause serious

personal injury.

Changing oil and cleaning the paver

should only be done in a designated area where the

oil and chemicals can be contained. Discard these

by-products in accordance with environmental

regulations.

Figure 5-11. Engine Oil Dipstick and Oil Filter

1 - Oil Filter

2 - Oil Dipstick

3 - Oil Fill Cap

To check the engine lubrication oil level:

1. Park the machine on a level surface and turn off the

engine.

2. Wait ve minutes to allow the oil to return to the oil

pan so you can obtain an accurate measurement of

the engine oil level.

3. Clean the area around the engine oil dipstick before

removing it from the engine.

4. Remove the dipstick from the engine and checking

the oil level. The oil level should be above the

ADD mark--but not above the FULL mark--on the

dipstick. Add oil if needed.

Change Air Filter

Never operate the engine without an

air lter properly installed. Severe damage to the

machine will occur.

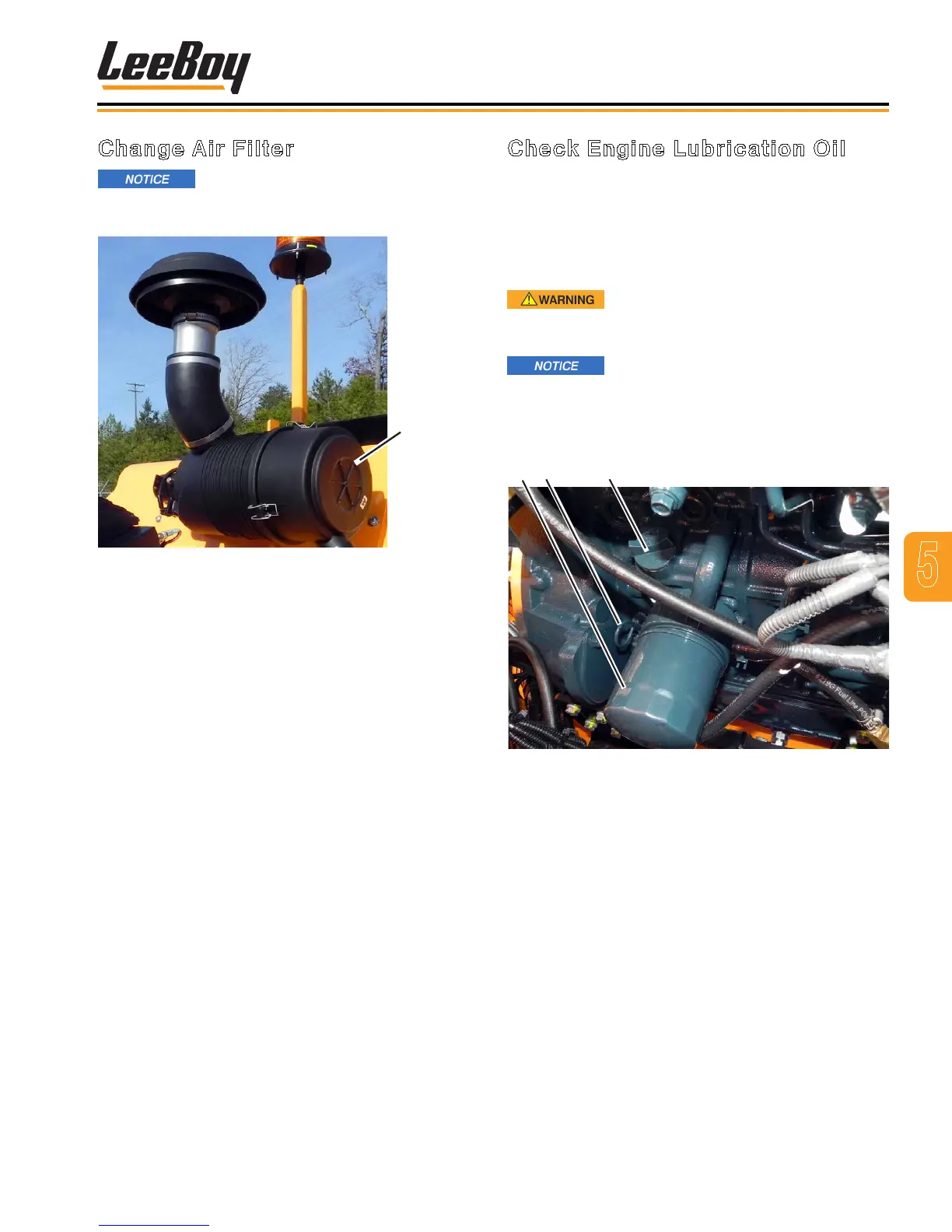

Air Filter

Cover

Figure 5-10. Air Filter Cover

To change the air lter elements:

1. Unclamp and remove air lter cover. (Figure 5-10)

2. Remove the primary and secondary air lter

elements. Discard.

3. Clean the inside of the air cleaner body with a clean

cloth.

4. Install new air lter elements inside the canister.

5. Reclamp cap onto the air lter cover.

6. Check clamps to ensure lter elements are tight and

lter elements are making proper contact.

7. Start engine. If engine does not run smoothly,

recheck lter element contact.

NOTE: The air lter elements should be replaced

every 250 service hours of normal paver

operation, but more often if the paver is

operated in severe conditions.

Loading...

Loading...