4

LeeBoy 6150 Conveyor Paver 4-5

Operation

DPF Regeneration (REGEN)

It is important to understand DPF regeneration before

operating the paver. DPF regeneration is the term given

to the cleaning process where the exhaust tempera-

ture is raised in an attempt to safely burn off any soot

and undesired combustion gas captured in the Diesel

Particulate Filter (DPF) in the exhaust system. When the

DPF lter reaches a soot saturation level between 25 -

45 percent, the onboard engine ECU (Engine Control

Unit) will activate a regeneration cycle.

To reduce the amount of particulate

matter and maximize efciency, use API-CJ4 (or

ACEA-E9 European equivalent) engine oil. Running

the engine at 1800 RPMs will also provide more

efcient operation and allow automatic regeneration

while paving.

During normal operation, the DPF is cleaned automati-

cally. Under certain conditions, the operator may have

to instruct the control system to perform the cleaning

process.

The DPF icon on the PV480 digital controller indicates

the level of soot build-up on a scale of Level 0 - 5. The

regeneration process will occur automatically at Level

1 - 2. The engine speed will increase during regenera-

tion and there may be a noticeable sound difference.

Once regeneration is complete, the engine will return to

normal idle speed.

Once the DPF cycle has been activated, it is important

not to shut off the engine as the regeneration cycle

will fail and could possibly damage the engine. If the

regeneration cycle fails, the ECU may attempt a second

regeneration depending upon how blocked the lter has

become. If the system does not allow a second regen-

eration, this means the lter is blocked more than 80

percent and needs to be cleaned or replaced.

It is important to perform a parked,

manual regeneration BEFORE the engine reaches as

high as Level 4. If the DPF reaches Level 4 - 5, non-

warranty factory assistance from the engine manufac-

turer is required.

DO NOT idle machine any longer than

necessary as too much idling can cause soot to build

up in the DPF, requiring more frequent regeneration.

PV480 Powerview Display

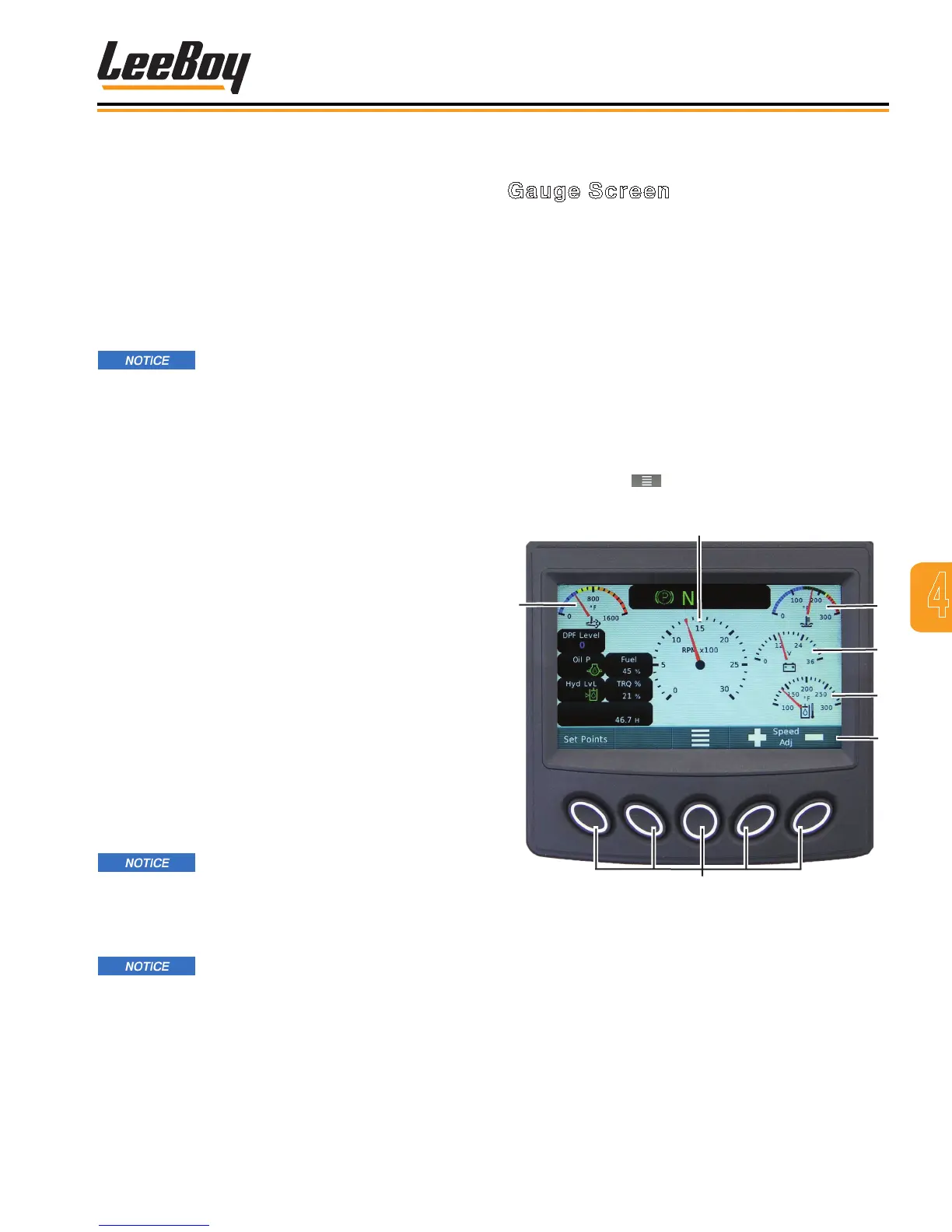

Gauge Screen

The Gauge Screen is the rst screen to appear on the

PV480 digital controller when starting the engine. This

is the default screen. (Figures 4-2)

Pressing the “soft key” buttons along the bottom of the

controller unit allows the operator to navigate to various

other screens. The banner icons along the bottom of

the screen correspond with these buttons, and change

accordingly when navigating to other screens as de-

scribed on the following pages. Table 4-2 on the next

page shows the icons that appear on the banner with

descriptions.

Pressing the Set Points button navigates to the Set

Point and Throttle Speed screen. (Page 4-7) Pressing

the center button ( ) always navigates to the Main

Menu screen. (Page 4-7)

1

2

3

Soft Keys

Figure 4-3. Gauge Screen

1 - After Treatment DPF Outlet Gas Temperature

2 - Engine Speed/RPMs

3 - Engine Coolant Temperature

4 - Electrical Potential Voltage

5 - Hydraulic Oil Temperature

6 - Soft Key Banner

Loading...

Loading...