3

Leeboy 6150 Conveyor Paver 3-3

Component Location

Engine

The LeeBoy Model 6150

Conveyor Paver is equipped

with a Kubota (V3800-

TIEF4BFT4) diesel engine.

This 74 HP (52 kW), turbo-

charged engine is a strong

performer that features the

latest technology. Fuel-

efcient and durable, this

electronically-controlled

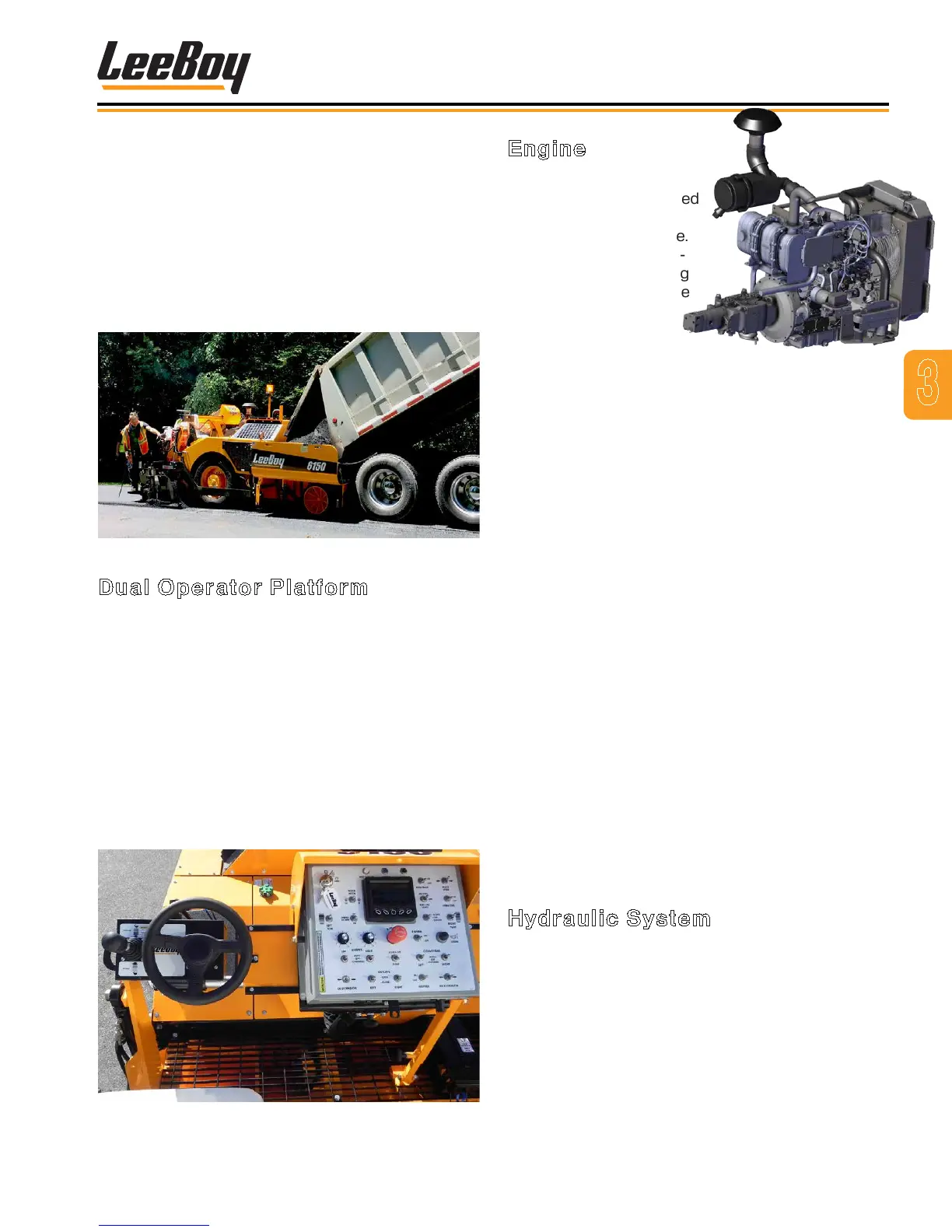

Components Overview

This section describes the major components for the

LeeBoy 6150 Conveyor Paver. This wheeled paver is

designed with front “bogie” tires and rear heavy-duty,

liquid ballast tires that help lower the center of gravity,

an important consideration when paving on a grade.

Wheeled pavers offer more mobility and on-site speed

than tracked pavers. Become familiar with the machine

components before operating the paver.

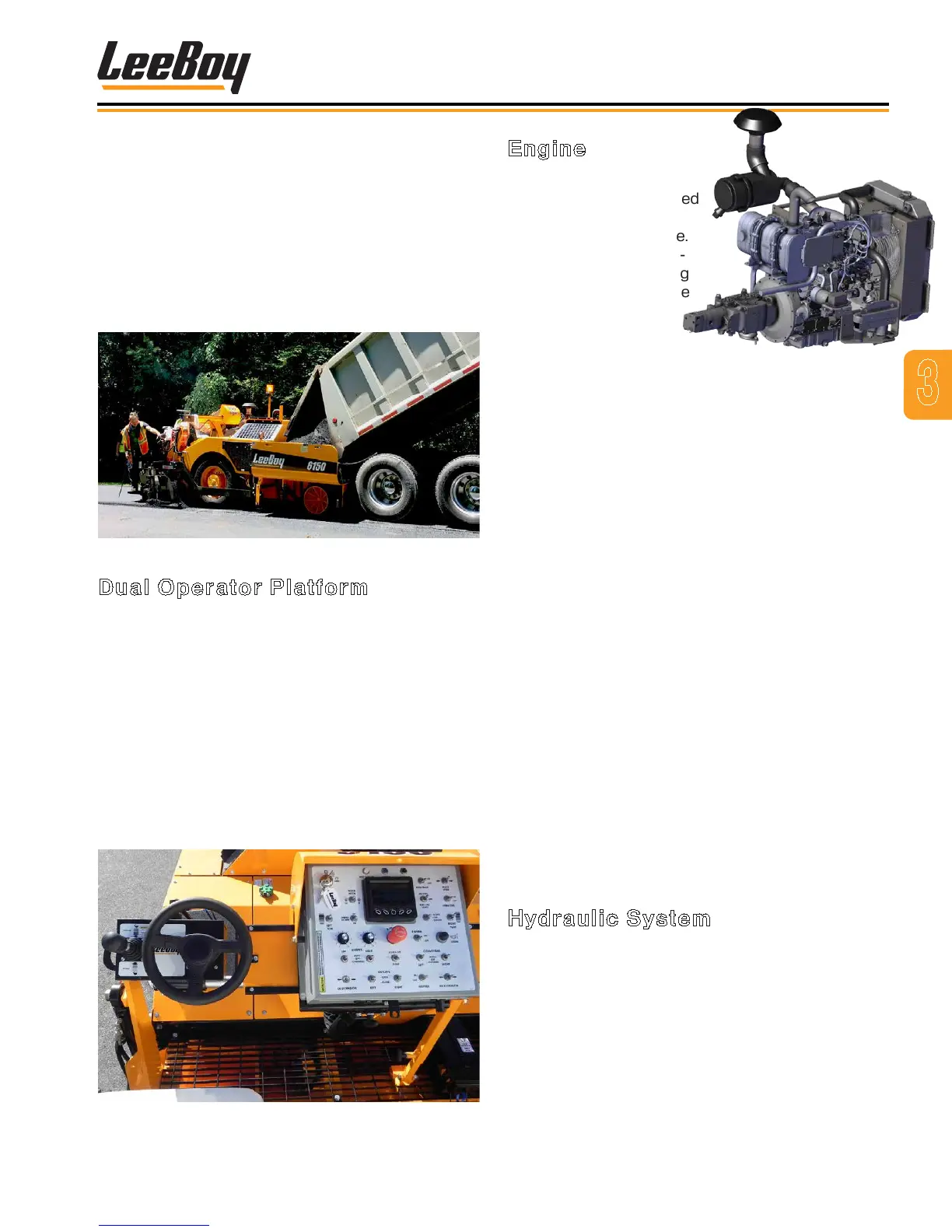

Dual Operator Platform

The operator platform allows easy and convenient

access to controls for paver work functions. Dual oper-

ator stations with steering wheel controls are standard

on this paver. The main control panel slides to either

side of the platform, featuring the PV480 digital display

controller, work function switches, and a vandalism

cover for security and protection.

The operator platform offers the versatility of a high

deck that can be manually lowered to a low-deck con-

guration for accommodating a screed operator while

paving. Remote screed control boxes are mounted on

each side for screed operator convenience.

engine offers the latest in innovative emission solutions

that comply with stringent regulations that optimizes

combustion and reduces pollution. This Tier 4 Final

engine complies with emission requirements estab-

lished by the U.S. Environmental Protection Agency

(EPA) to reduce diesel particulate matter (DPM) and

other toxins released into the air.

Advanced emission-control devices and low-sulfur fuel

requirements--only Ultra-Low Sulfur Diesel (ULSD) can

be used in these engines--combine with after-treatment

methods such as Exhaust Gas Recirculation (EGR) and

Diesel Particulate Filters (DPF).

The air cleaner removes ne particles such as dust,

sand, chaff and lint from the air. As air is taken into the

air cleaner assembly, the cyclone action deposits some

of the ne particles in the evacuator that is mounted

on the bottom of the air cleaner housing. The fuel lter

removes contaminants from diesel fuel before it ows

into the injection pump where it is injected into the

engine combustion chamber.

The radiator mounted in front of the engine cools the

engine. As coolant ows through the radiator, airow

from the engine-driven fan removes heat.

Refer to the Engine Operator’s Manual accompanying

your paver for additional engine information.

Hydraulic System

The hydraulic system includes two hydraulic pumps

(three if equipped with the electric heat option),

hydraulic motors and cylinders that work together for

optimum machine component control. Valves regulate

the directional, pressure and uid ow throughout the

hydraulic system. Hydraulic test ports add ease and

convenience for checking and troubleshooting hydraulic

pressure for four of its main functions.

Loading...

Loading...