5-24 LeeBoy 6150 Conveyor Paver

Maintenance

Conveyor Switch Replacement

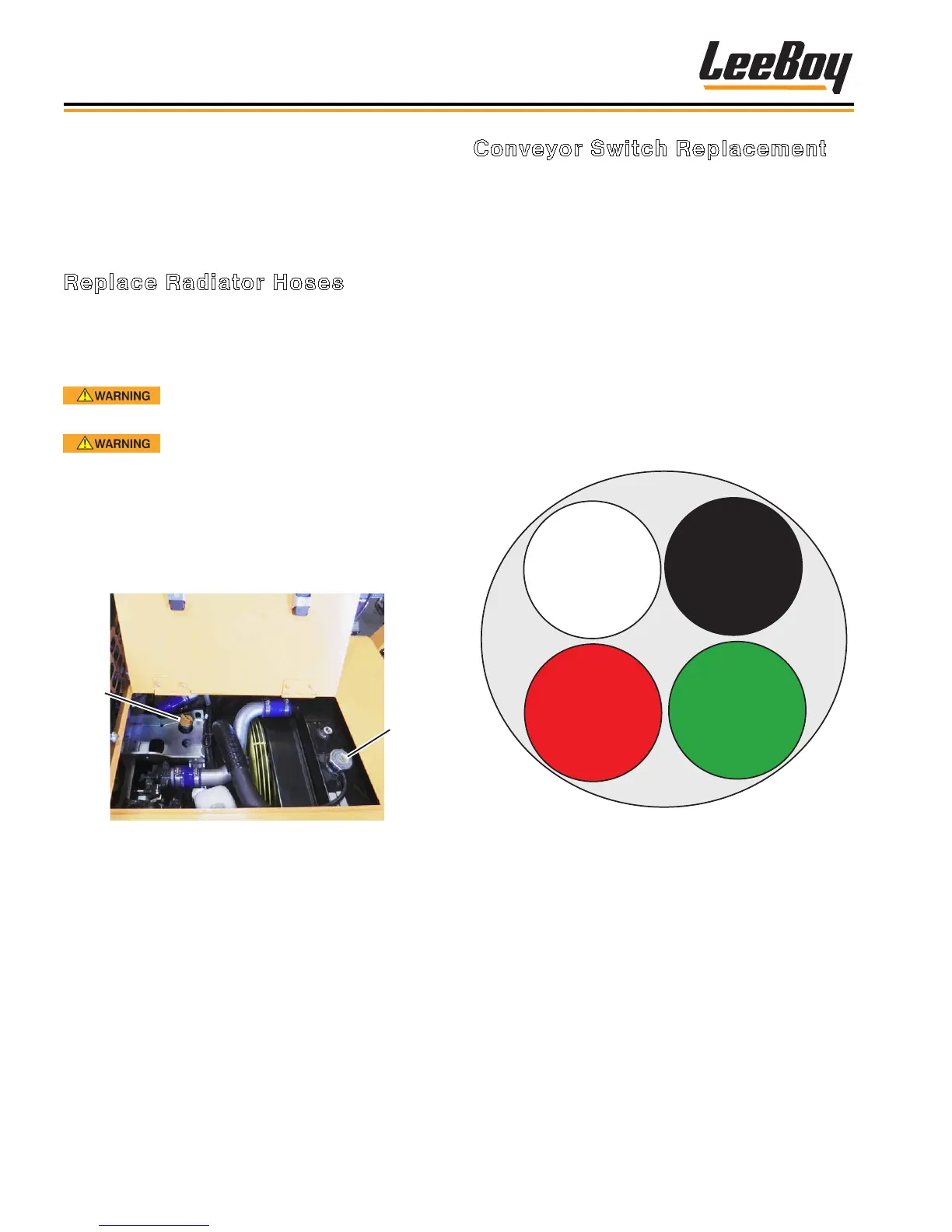

If you need to replace the conveyor switches, follow

these instructions, using the color codes for wiring

(Figure 5-26) to ensure the conveyor switches on the

conveyor ap are wired correctly:

1. Raise the conveyor ap 6-1/2 to 7 inches (16.5 to

17.8 cm) from the bottom of the tank mount support.

2. With the switch installed and the conveyor paddle

hanging down:

• Using a multimeter, measure the ohms across

the black and white wires.

• Using a multimeter, measure the ohms across

the red and green wires.

4

WHITE

3

BLACK

1

RED

2

GREEN

Figure 5-26. Conveyor Switch Wiring

3. Wire the switch using the wires that show continuity.

4. Repeat Steps 2 - 3 for the second switch.

NOTE: The switches are sealed and potted,

therefore, they are not serviceable.

Replacement Procedures

Refer to your Engine Operator and other manuals

accompanying your machine for additional component

replacement procedures.

Replace Radiator Hoses

Radiator hoses should be replaced if worn or frayed.

(See Section 7, Illustrated Parts List (IPL) for hose

and component replacement part numbers.) Access the

radiator from the top access panel.

This procedure should only be

performed when the machine is not running.

DO NOT remove the radiator cap while

the engine is still hot. The radiator is under pressure

serious injury can occur if removed while hot.

1. Turn off ignition, remove key, and allow the engine to

cool down.

2. Carefully remove the radiator surge tank cap.

(Figure 5-25)

Engine

Oil

Radiator

Cap

Figure 5-25. Radiator (and Engine Oil) Cap

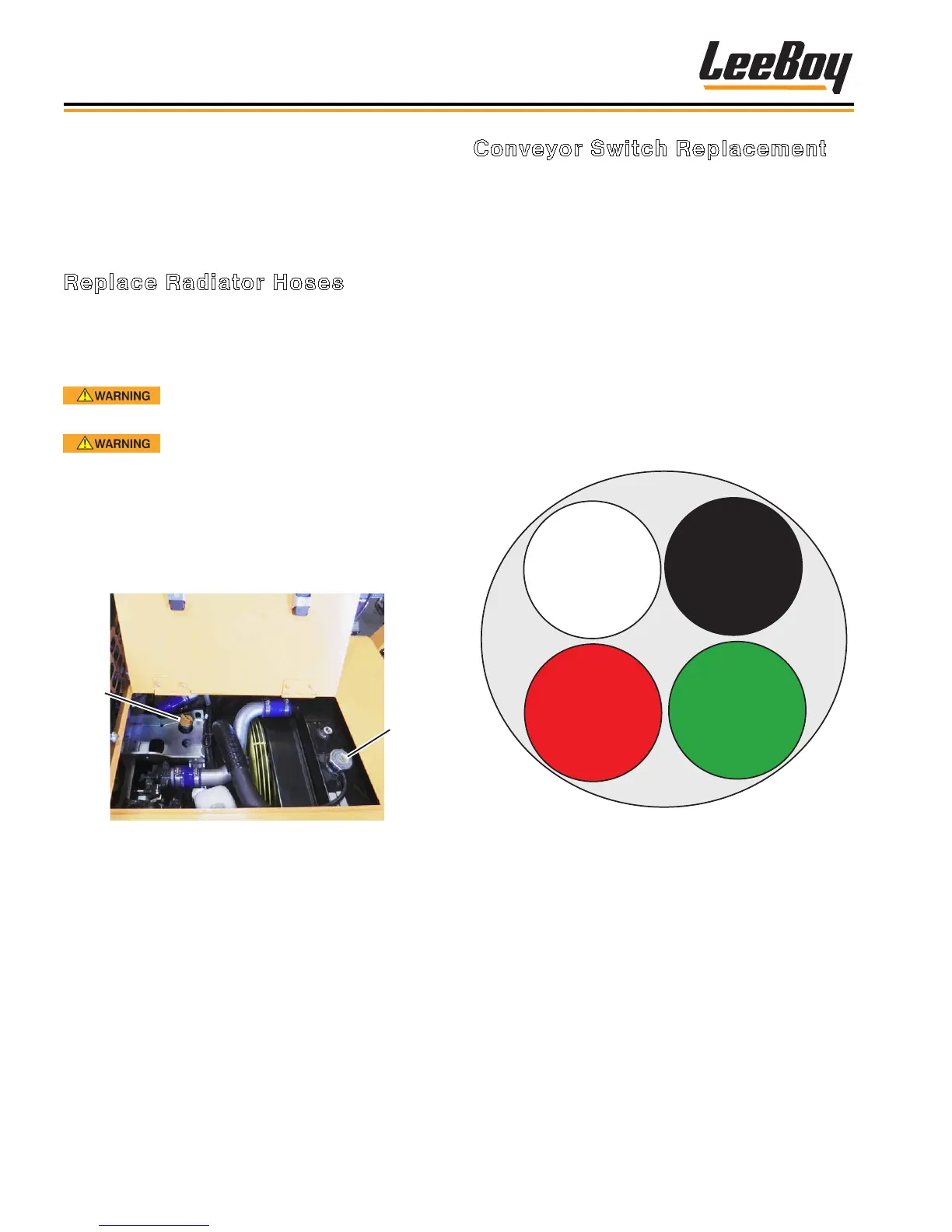

3. Locate radiator drain hose inside the left engine

access panel. Open petcock and drain radiator uid

into a container large enough to hold 5.5 gallons

(20.8 liters).

4. Remove the upper and lower hoses by loosening

the hose clamps on each.

5. Disconnect hoses and inspect for damage.

• If clamps are not damaged, retain to reinstall.

Replace if damaged.

6. Install new hoses and reconnect with hose clamps.

Loading...

Loading...