5-8 LeeBoy 6150 Conveyor Paver

Maintenance

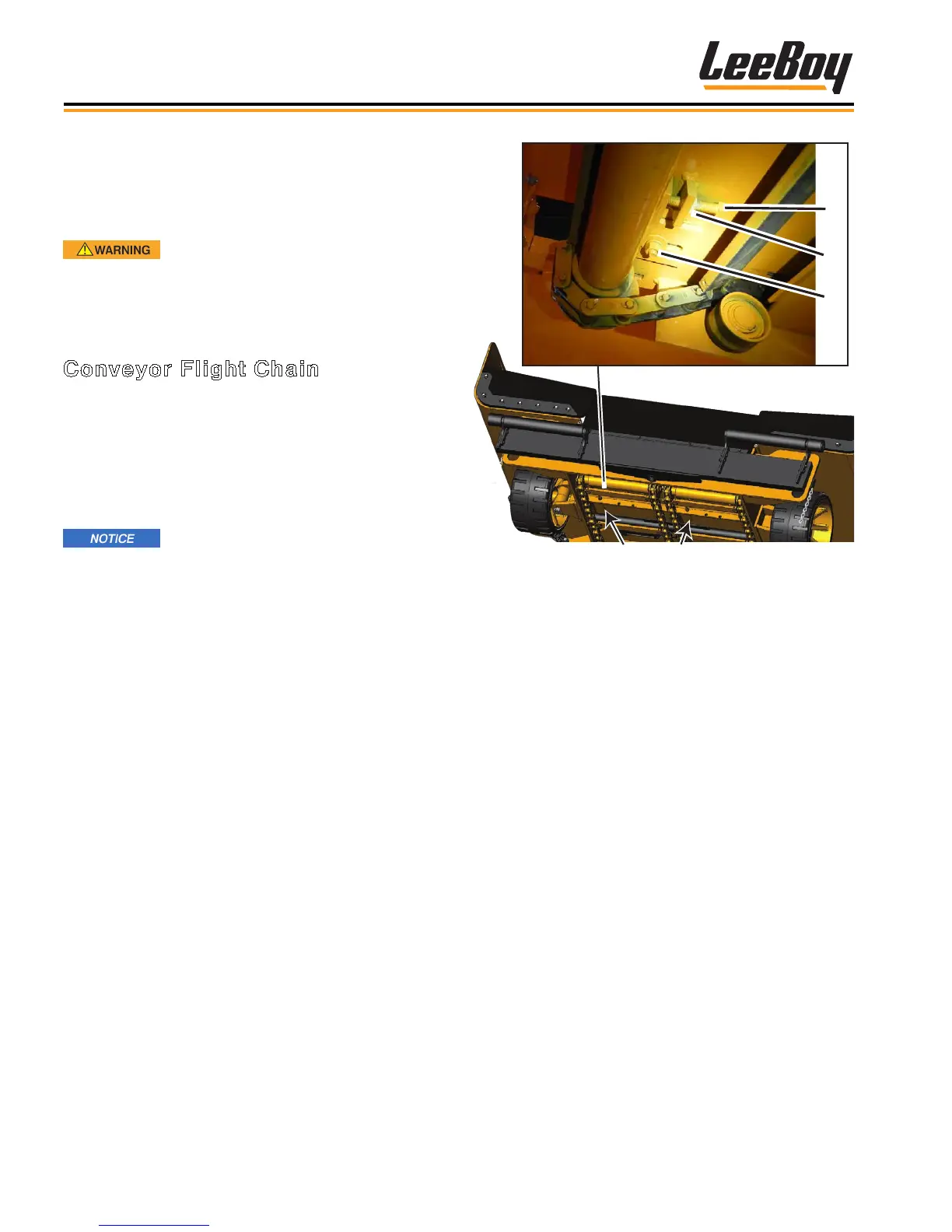

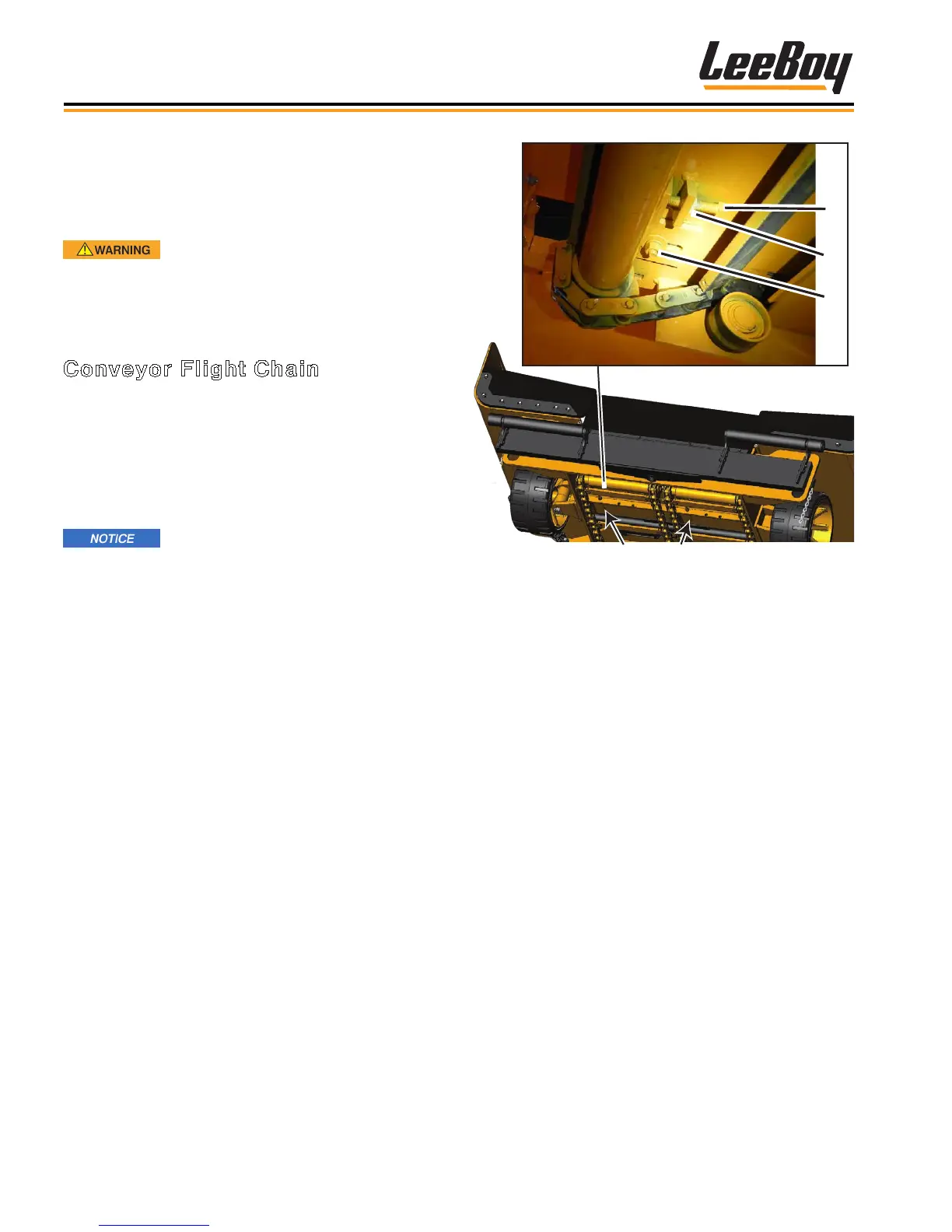

Figure 5-3. Conveyor Flight Chain Adjustment

1 - Adjustment Bolt

2 - Locking Nut

3 - Hold-Down Nut

4. Turn each adjustment bolt alternately the same

amount. For example, turn one bolt one half turn,

then the other bolt one half turn, etc.

5. Continue alternating tightening until the ight chains

are tight. (The pressure on the chain will be notice-

able as the bolts are tightened.)

NOTE: Drag chains should be 1/2-inch away from

rear frame channel.

6. After the conveyor chain tension is set, retighten

locknuts and bolts holding the ight chain assembly.

7. Repeat steps 1 through 4 for the opposite side.

8. Grease front and rear conveyor tubes at grease

blocks on each side of conveyor.

Maintenance Adjustments

Certain components of the paver need adjustments

for optimum performance, operation and general

maintenance.

Entanglement hazard! DO NOT run

the engine while checking and servicing conveyor

components. NEVER perform any adjustments while

the engine is running.

Conveyor Flight Chain

Maintaining the two conveyors in proper adjustment

will ensure maximum service life from the conveyors,

sprockets and shafts. The conveyor ight chains must

be adjusted every 100 hours for optimum performance.

(Figure 5-3) If irregular movement of the conveyor

occurs, an adjustment is needed regardless of the time

interval. (See Page 5-33 for slack tension adjustment.)

Keep conveyor ight chain properly

oiled with cleaning solvent or release agent during

cold weather to keep conveyors functioning

smoothly.

NOTE: If the adjustment bolt has reached its

maximum adjustment level, remove the half

link in the conveyor chain. This repair should

bring the adjustment bolts back to full travel.

There are four (4) adjustment bolts, two (2) for each

conveyor. Use the following procedure to make this

adjustment on both sides of the conveyor:

1. Move front of paver onto a ramp and block with

wheel chocks to prevent the paver from moving.

2. Loosen the hold-down nuts (one on each side of

each adjustment bolt). (Figure 5-3)

3. Loosen each locking nut beside the adjustment bolt.

Loading...

Loading...