5-22 LeeBoy 6150 Conveyor Paver

Maintenance

Liquid ballast types include:

• Water: Plain water is inexpensive, but it freezes. Ice

expands and will push the tire off the rim. Even in

Florida, there is a chance of freezing during winter, so

water is not recommended unless.

• Calcium Chloride: This toxic, highly corrosive

chemical is sold in ake form to mix with water, adding

considerable weight to the water. It resists freezing

down to -50° F (45.5° C), but will rust wheels in a very

short time, which can adversely affect your warranty.

Therefore, it is NOT recommended for use.

• Antifreeze: Antifreeze added to water resists freezing

down to -40° F (-40° C) and does not add weight

to the water, which is eight pounds per gallon. It is

economical and readily available. Ethylene glycol

antifreeze is toxic to animals: It only takes a little to

poison pets.

• Beet Juice: A fairly new product on the market is beet

juice, sold under the name “Rim Guard,” which resists

freezing down to -35° F (-37° C), is noncorrosive,

environmentally friendly, and 30 percent heavier than

water. It is expensive compared to antifreeze.

NOTE: Foam lling is NOT recommended due to the

expense, inability to adjust tire pressure for

the job, and damage that can occur. You will

have to cut the tire off the wheel--and buy new

wheels--when you want to change tires. If

using this method, it must be professionally

done.

It is important to displace most of the air when inating

the rear tires with liquid ballast, allowing the tire to be

inated to a relatively low pressure for proper footprint

and maximum tractive effort. Do not deviate from the

following procedure:

1. Mix the ethylene glycol antifreeze solution at a

50/50 ratio in a large container with hose/pump

attachment. A ll nozzle with valve that allows

displaced air to escape as the uid enters must be

used.

2. Support the axle to take the machine’s weight from

the tires and deate.

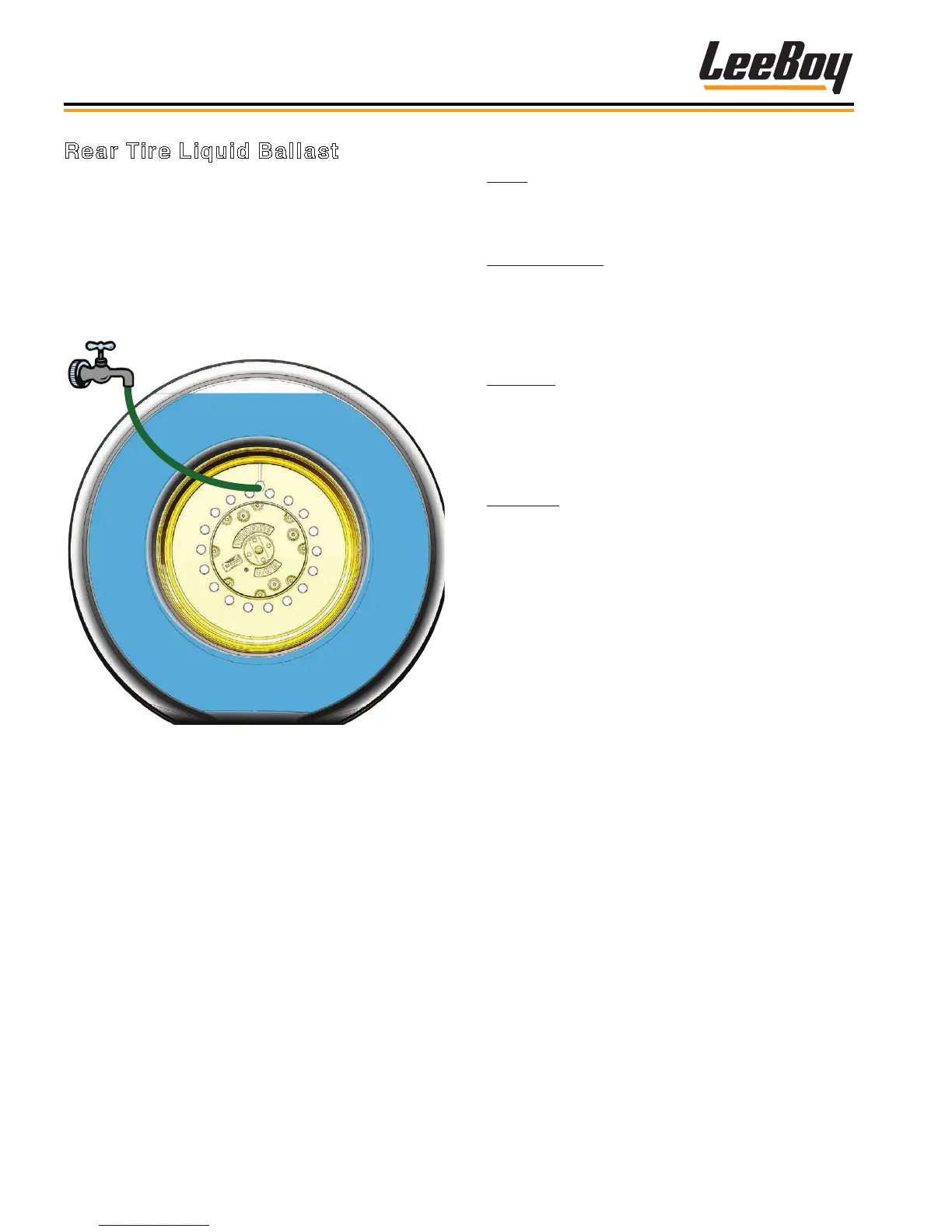

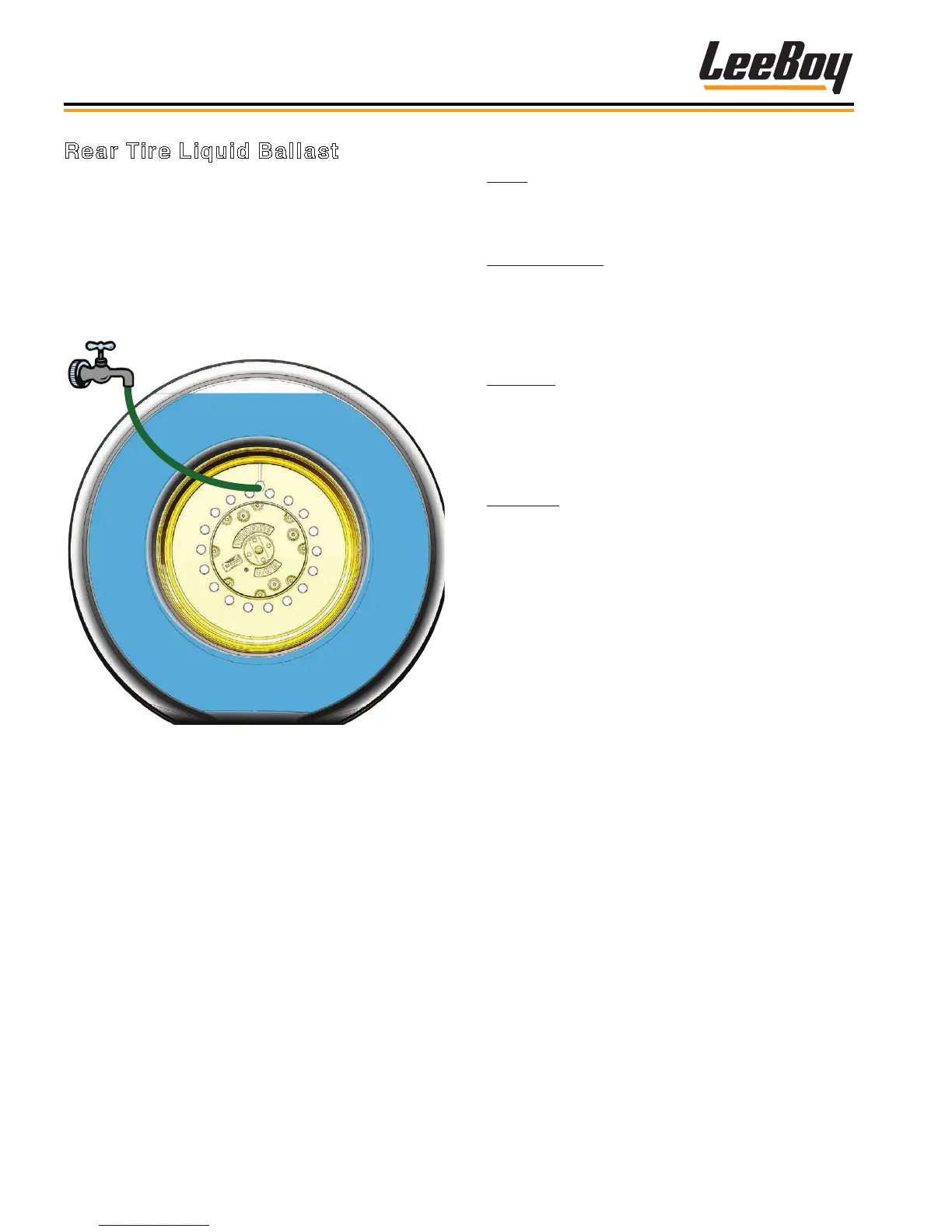

Rear Tire Liquid Ballast

Pumping liquid ballast into the drive tires stiffens the

tire sidewalls, helps prevent slippage, decreases tire

compaction on the paving surface, and adds weight

to the lowest center of gravity. This additional weight

absorbs surface bumps, reducing wheel bounce that

can affect the quality of paving. (Figure 5-22)

NOTE: Always inspect the tire, rims and wheel for

damage before inating.

Figure 5-22. Liquid Ballast at 95 Percent Level

Most tire manufacturer suggest adding up to 95

percent liquid ballast volume, depending upon the

situation. Changes in weather, temperature extremes,

type of liquid ballast used, job site requirements and

weight split between the front and rear axles are major

considerations.

• If the front axle needs to be lighter, evacuate the liquid

ballast.

• To add weight at the rear axle for heavy torque work,

pump ballast into the rear tires.

Consult your tire manufacturer (or ballast product

manufacturer) for proper ballasting ination calculations

and values. (You may also need to purchase a water

ller attachment.)

Loading...

Loading...