55

LeeBoy 6150 Conveyor Paver 5-7

Maintenance

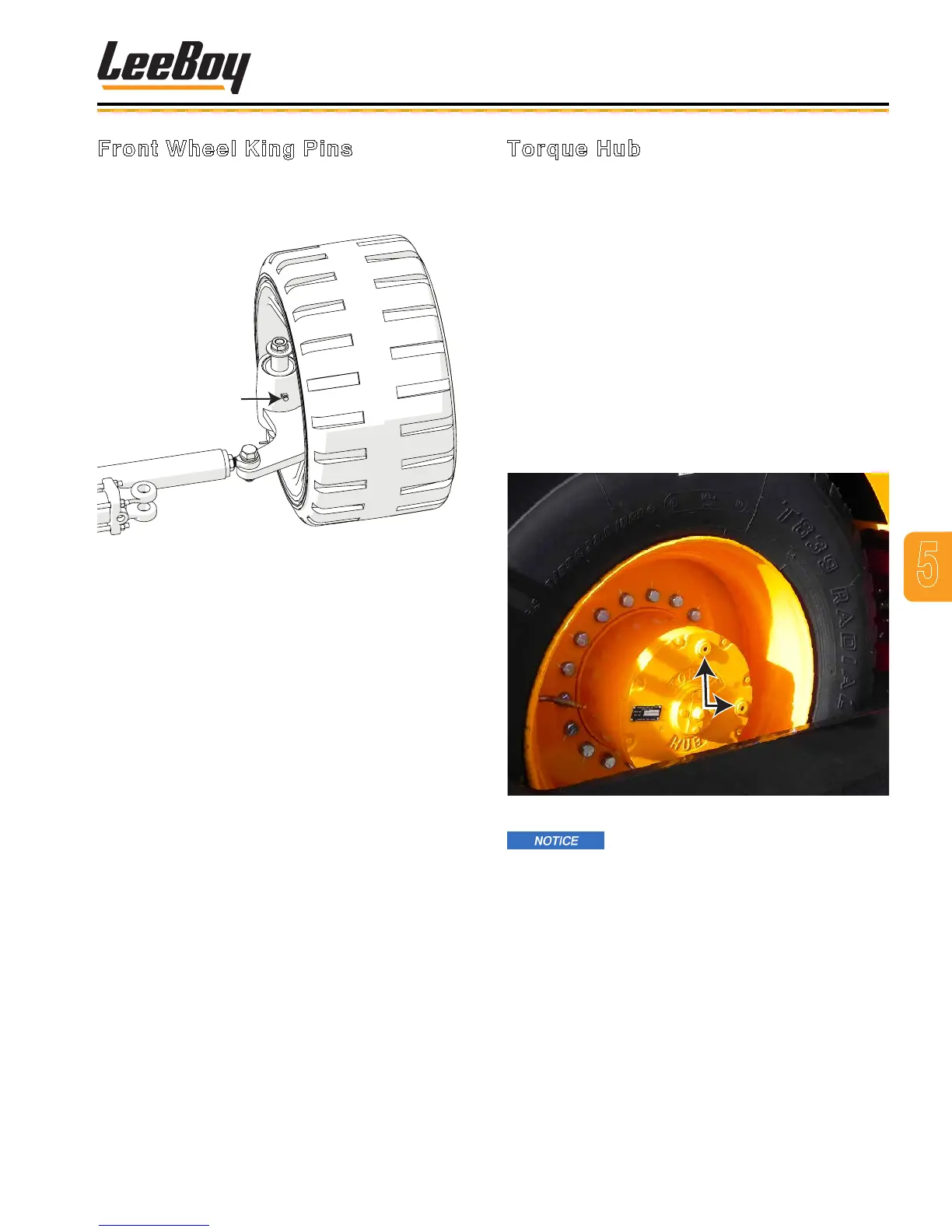

Torque Hub

The torque hubs are mounted directly onto the rear

wheels. (Figure 5-2) It is important to keep the torque

hub oil at the proper level for lubricating these moving

parts. Be sure to change the torque hub oil every six

months.

1. Remove the plug in the 3 o’clock position. (Figure

5-2)

2. If oil comes out, no oil is needed. Reinsert the plug

and tighten.

3. If oil does not come out, remove the top plug and ll

with SAE 90 WT gear oil until oil starts to appear at

the 3 o’clock plug.

4. Replace both plugs and repeat process on the

other torque hub.

Figure 5-2. Torque Hub Plugs in 3 O’Clock Position

Changing oil and cleaning the paver

should only be done in a designated area where the

oil and chemicals can be contained. Discard these

by-products in accordance with environmental

regulations.

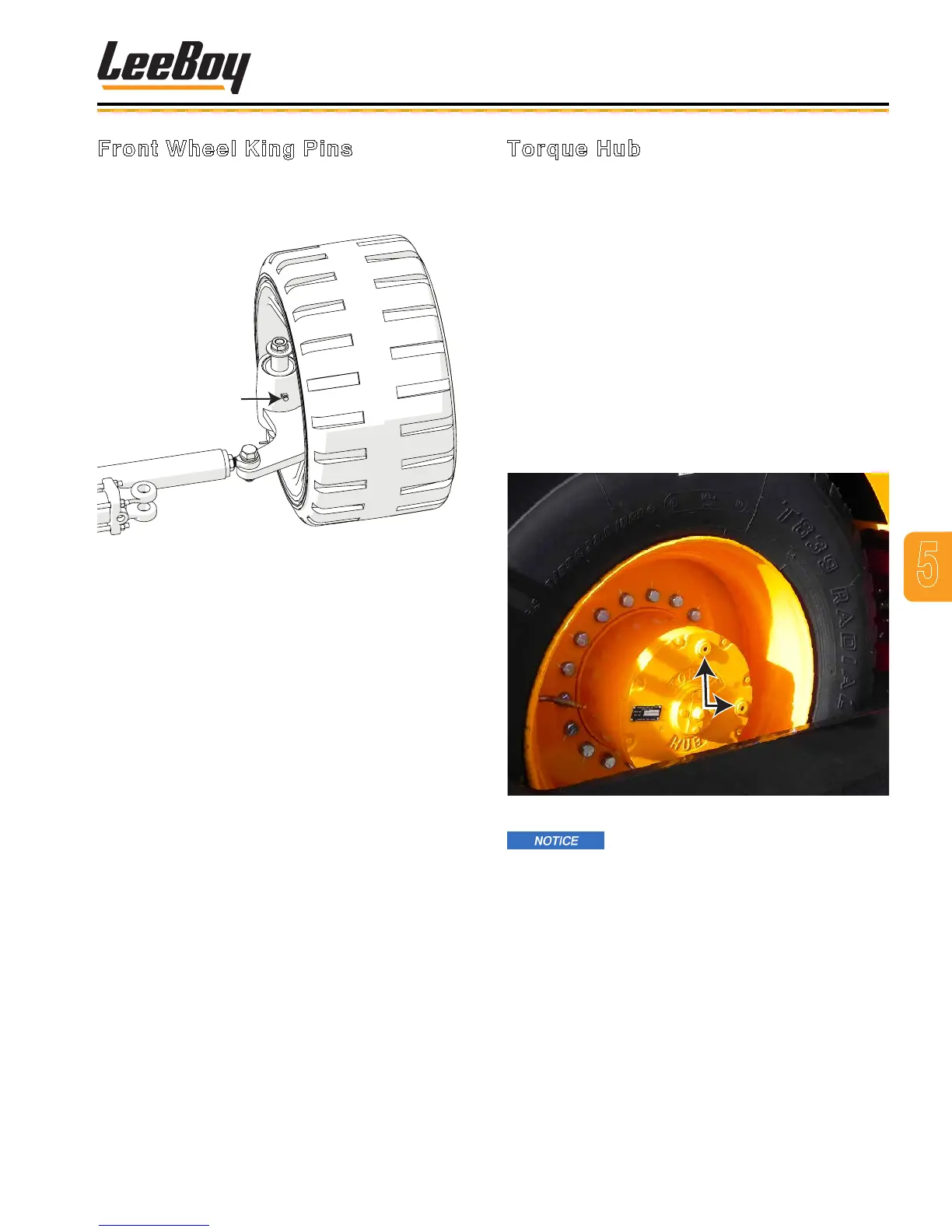

Front Wheel King Pins

It is important to grease the front wheel king pins (and

bushings) every 100 hours of service. The king pin

attaches each front bogie wheel to the hopper frame.

Grease

Fitting

Figure 5-1. Front Wheel King Pin Grease Points

Use the following procedure for lubricating the king pin

components:

1. Locate and clean the grease tting lubrication point.

(Figure 5-1)

2. Apply one shot of grease to each tting with a

manual (hand) grease gun.

3. Wipe away any excess grease.

Loading...

Loading...