4

LeeBoy 6150 Conveyor Paver 4-27

Operation

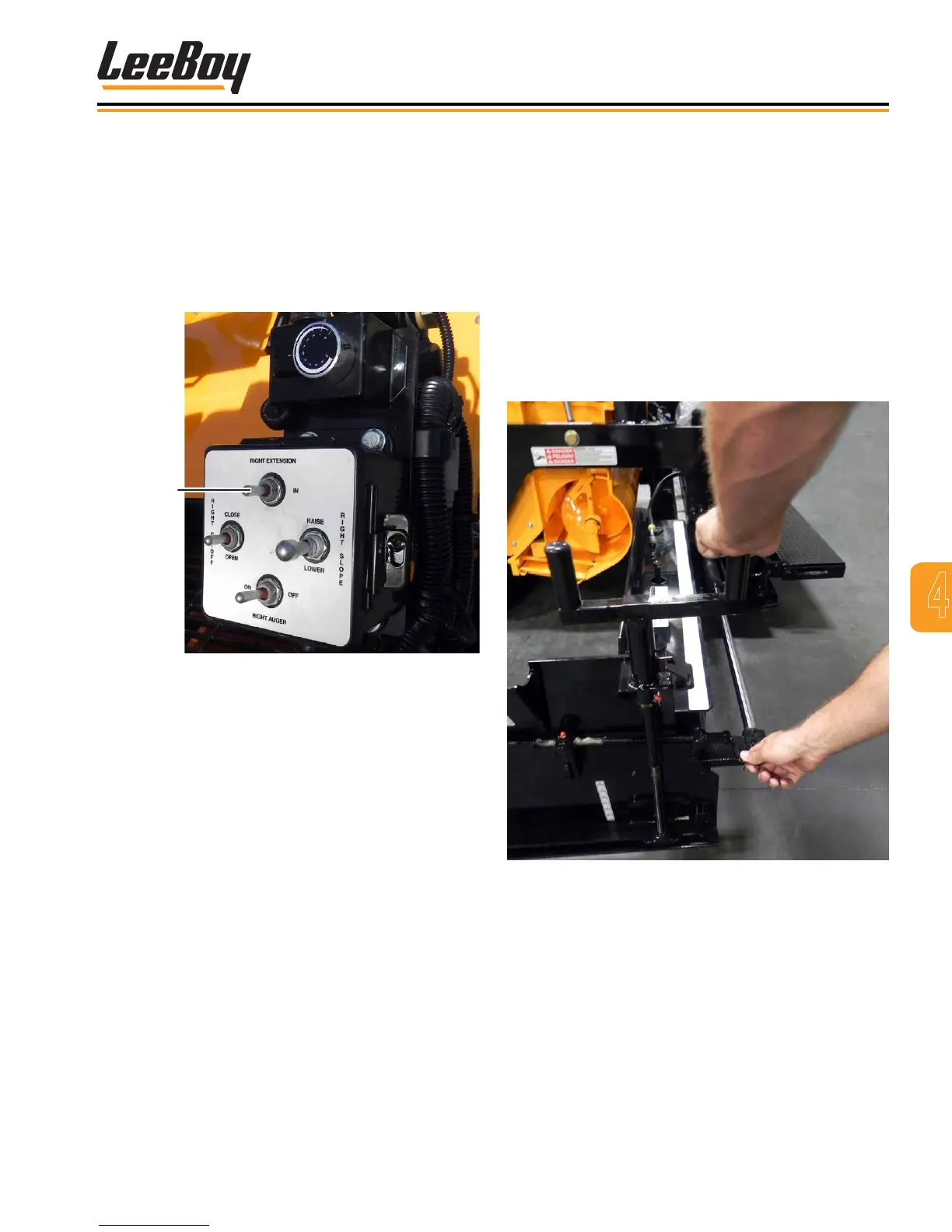

6. Turn the tilt screw so the front of the endgate tilts

down slightly when the screed is lifted. This will allow

the endgate to set itself to the grade. (Figure 4-57)

NOTE: Never allow the endgate to carry the weight of

the screed to prevent uneven compaction.

7. If the endgate digs into the asphalt at the front,

adjust the tilt screw until the endgate tilts back more.

8. On the rst pass, leave approximately six to eight

inches (15 - 20 cm) of unrolled asphalt where the

joint will be made.

9. When making a joint, the endgate must be set to

where it ts ush with bottom of screed.

Figure 4-57. Endgate Tilt Screw Adjustment

NOTE: Keep runners clean. When making a joint,

spray solvent on the runners.

10. If the joint looks too high or too low, adjust the ight

screw on the screed one turn at a time and allow

four to ve feet (1.2 - 1.4 m) of travel to correct itself.

NOTE: Too much adjustment up or down may cause

uneven pavement.

11. If making a cold joint, set the endgate down about

1/4 inch (6.35 mm) for a nice, even edge.

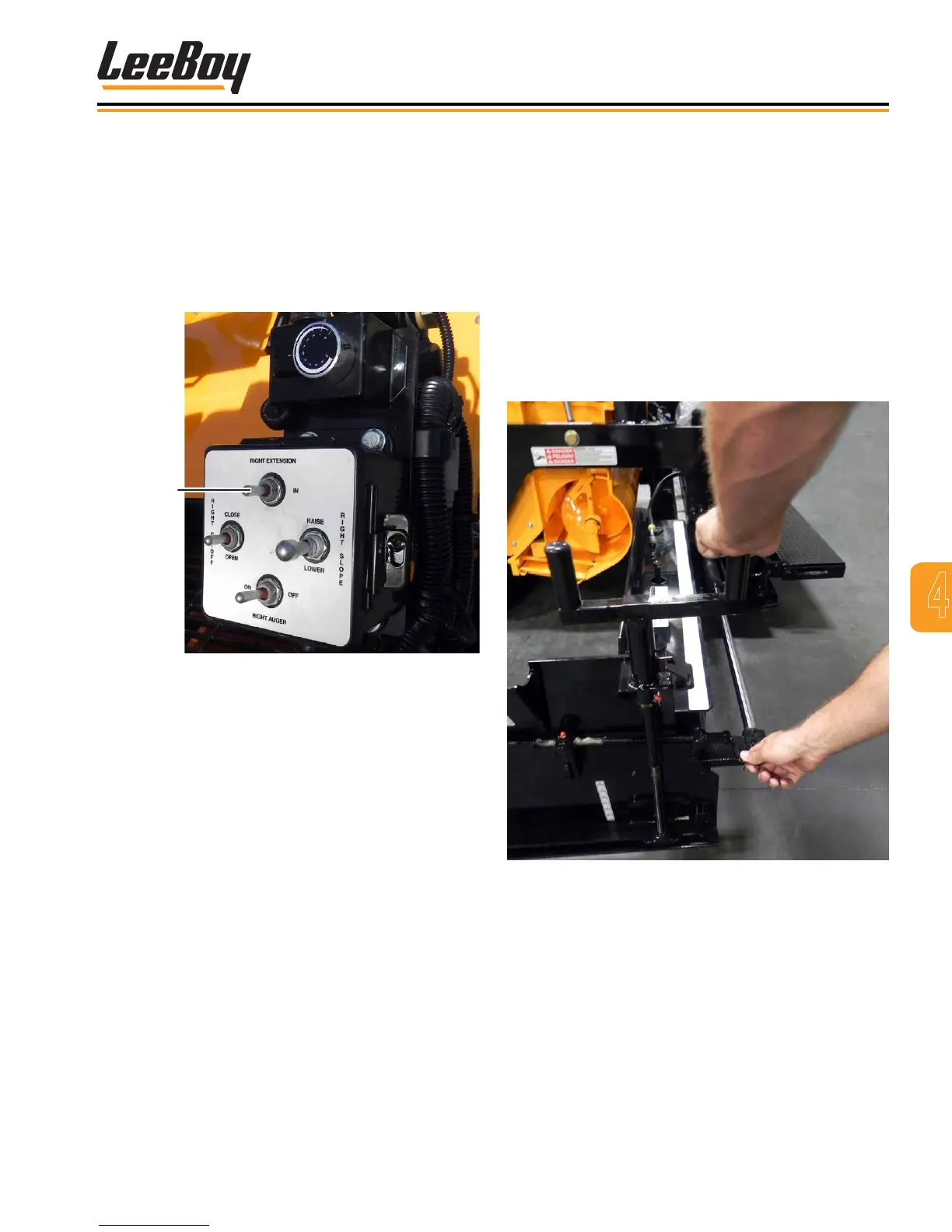

You can extend or retract the screed extension using

the extension switch on the main control panel. (Pages

3-6 to 3-11) A remote control box is also provided on

both sides of the main screed with switches to extend or

retract the screed, set the slope, open/close the cut-off

gates and turn the auger on and off while paving. (Fig-

ure 4-56) (If equipped with the optional sloping exten-

sions, an additional switch for this feature is also located

on the remote control box.)

Left or

Right

Extension

Switch

Figure 4-56. Remote Control Box and Auger Dials

Adjust the screed extension while paving using the fol-

lowing procedures:

1. Move paver to the starting position for paving.

2. Extend the screed to the desired width.

3. To set the depth, you can place small starter blocks

as shown in Figure 4-55.

4. Level the screed using the tow point.

• Refer to the elevation gauge (one on each side

of the paver for your convenience). Raise or

lower until the rod end of the cable is ush with

“0” on the gauge. Make minor adjustments if

needed.

5. On the rst pass, turn the endgate depth screw to

lower the endgate until it is about 1/4-inch (6.35 mm)

below the screed. (Figure 4-54)

Loading...

Loading...