CHAPTER 3: SETTING INTO OPERATION 3 - 5

TRYTON 112 CNC

Note :

During the

alignment,

ensure that

there is no

reduction unit

in the spindle

(spindle

liner).

Note :

The locking

nuts(A) of the

levellers, must

not be

tightened until

the bar-feeder

has been

anchored to

the ground.

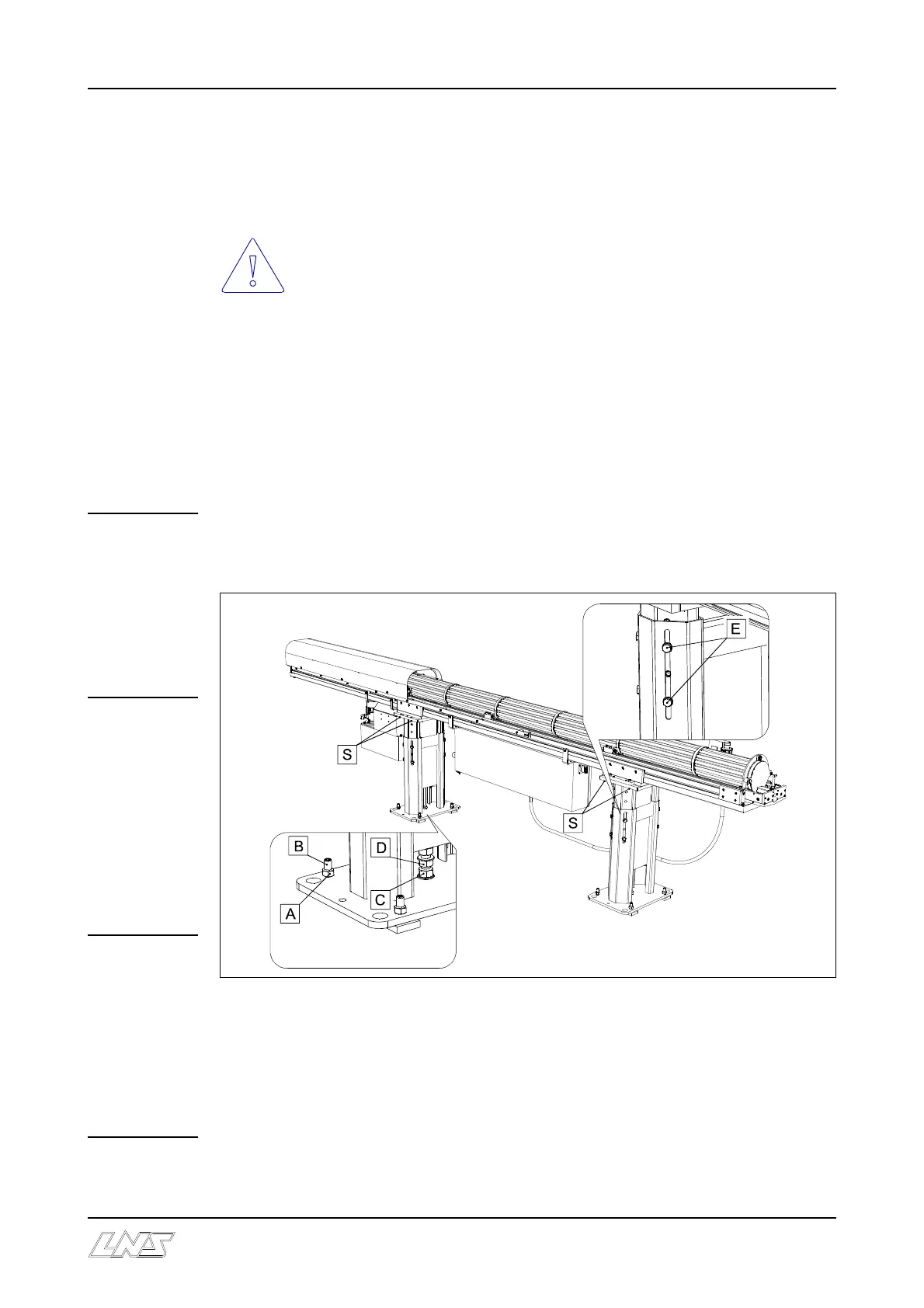

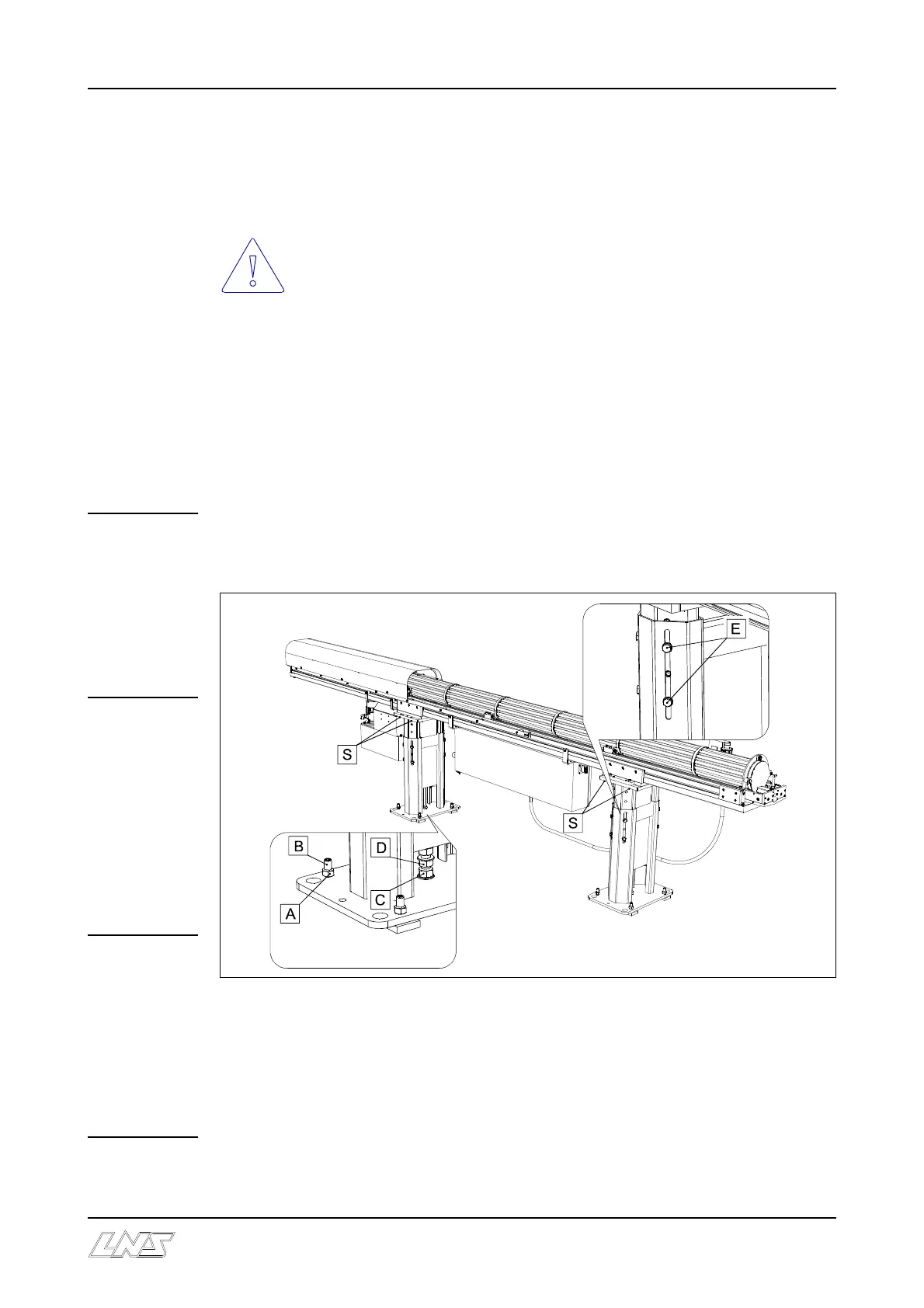

2. MOUNTING

The Tryton 112 bar feed system is delivered completely assembled. Because of this, it is

possible to proceed directly to its alignment when in place behind the lathe.

If the bar-feeder is equipped with a lateral pivoting device then, for safety

reasons, the 4 safety screws (S) must not be removed until after the bar-feeder

has been anchored to the ground.

Depending to the type of the lathe, the installation of some adaptation parts is needed

between the lathe and the feeder. Please check with your local LNS agent.

2.1 Alignment

Important : Before proceeding with the alignment of the bar feed system, ensure that

the lathe is stable and preferably leveled.

The alignment may be carried out using a nylon string, an optical tool, etc. If you do not

have any alignment tools, contact LNS or their local representative so they may take care

of the bar feed system installation.

C On each foot, loosen the lock nuts (A) of the leveling screws (B). Then, make sure that

the weight of the bar feed system is evenly distributed over the 8 support points.

C Loosen the lock nuts (D) and make sure that the central screws (C) of the front and rear

feet are supported.

C Loosen the locking screw (E).

Loading...

Loading...