CHAPTER 9 : MALFUNCTIONS 9 - 5

TRYTON 112 CNC

2. MAINTENANCE

Please read the safety instructions provided at the beginning of this manual

before handling the following devices.

2.1 Hydraulics

It is important that the bars be cleaned

before being inserted into the barrel of the

feeder. Indeed, excessive dirt can obstruct

the filter and so slow down the return of

the oil.

Filter cleaning procedure

The frequency with which the filter is

cleaned, depends on the type and

cleanliness of the bars used.

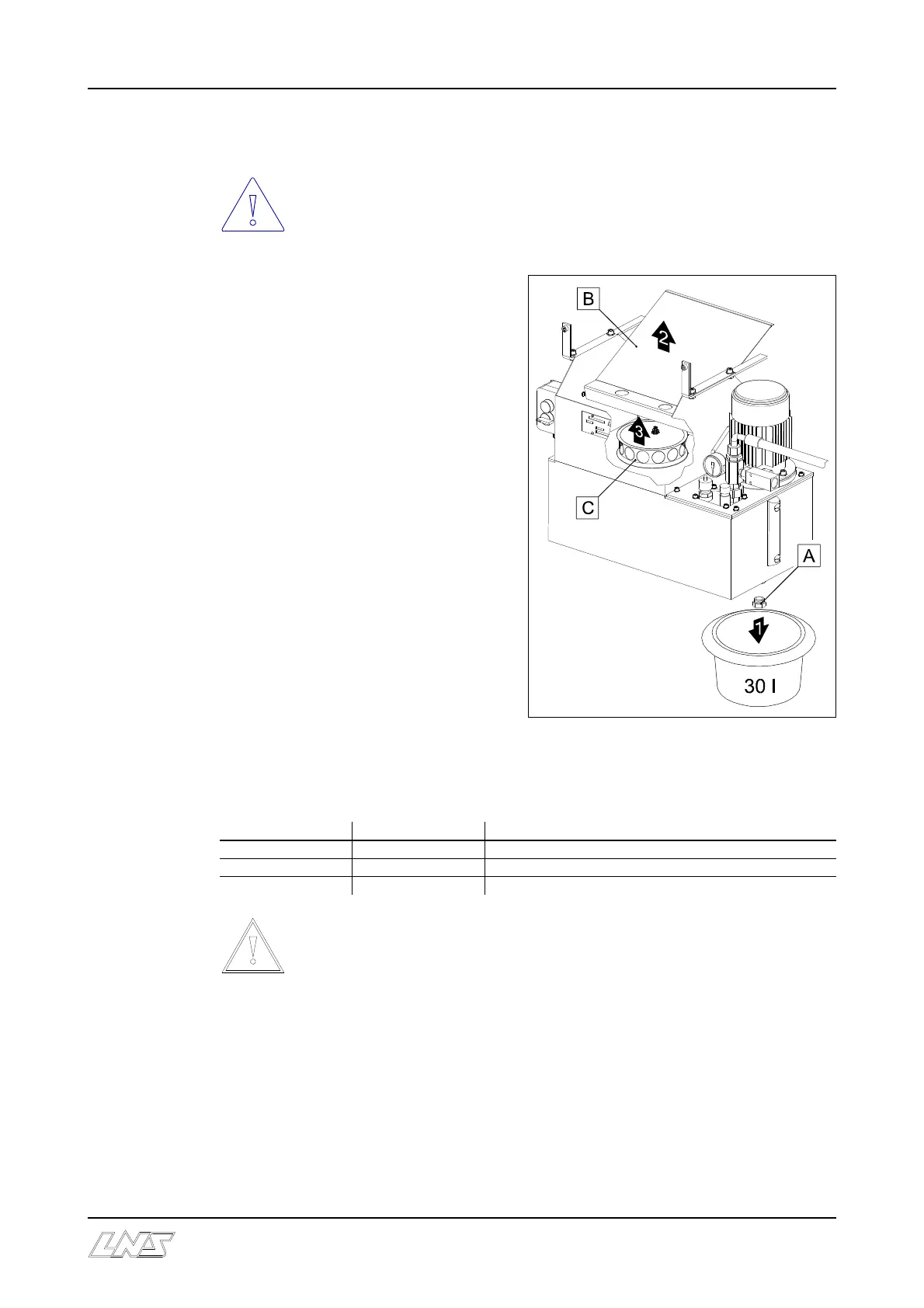

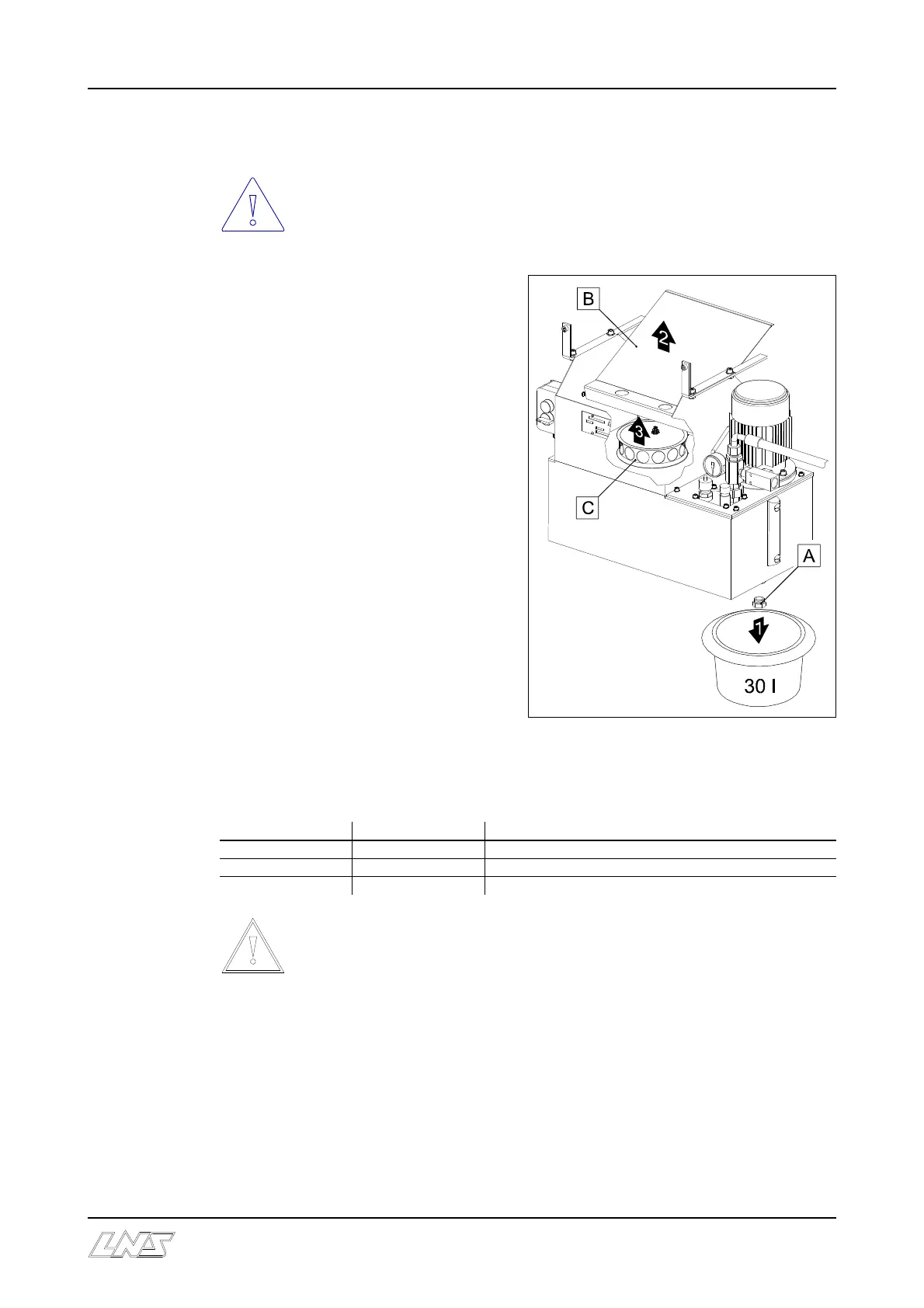

1. Place a container with a capacity of at

least 30 litres under the hydraulic fluid

tank. Remove the drain plug (A) and

empty the hydraulic fluid tank.

2. Remove any metal scraps, then lift the

collection plate (B).

3. Extract the filter (C) by pulling it

upward.

Clean the filter in a bowl of benzene. Clean the hydraulic fluid tank with a rag, then replace

the drain plug and filter.

Fill the tank with fresh oil, then lower the collection plate.

Désignation Article No Description

A Drain plug

B 112.12.033 Metal scrap collection plate

C 112.012.014 Filter

Never work without a filter or with a pierced filter. Danger of damaging the

pump and assembly !

2.2 Pneumatics

The air-filtering device is equipped with an automatic drainage valve, making it unnecessary

to empty it. The water recuperated comes from the pneumatic circuit of the building. It is

advisable to make certain that the air received by the bar feed system is as dry as possible

(see Chapter 5 / Pneumatics).

Loading...

Loading...