3 - 6 CHAPTER 3: SETTING INTO OPERATION

TRYTON 112 CNC

• Place a spirit-level transversally across the aluminium chassis of the bar-feeder.

Adjusting the screws (B), set the lateral level of the bar feed system.

• Adjusting the central screws (C), set the height of the bar feed system.

• Together with the vertical alignment, proceed with the lateral alignment, by shifting the

apparatus.

• When the alignment is satisfactory, tighten all locking screws (E) and nuts (D). Check

the alignment and, if necessary, correct it with the screws (B).

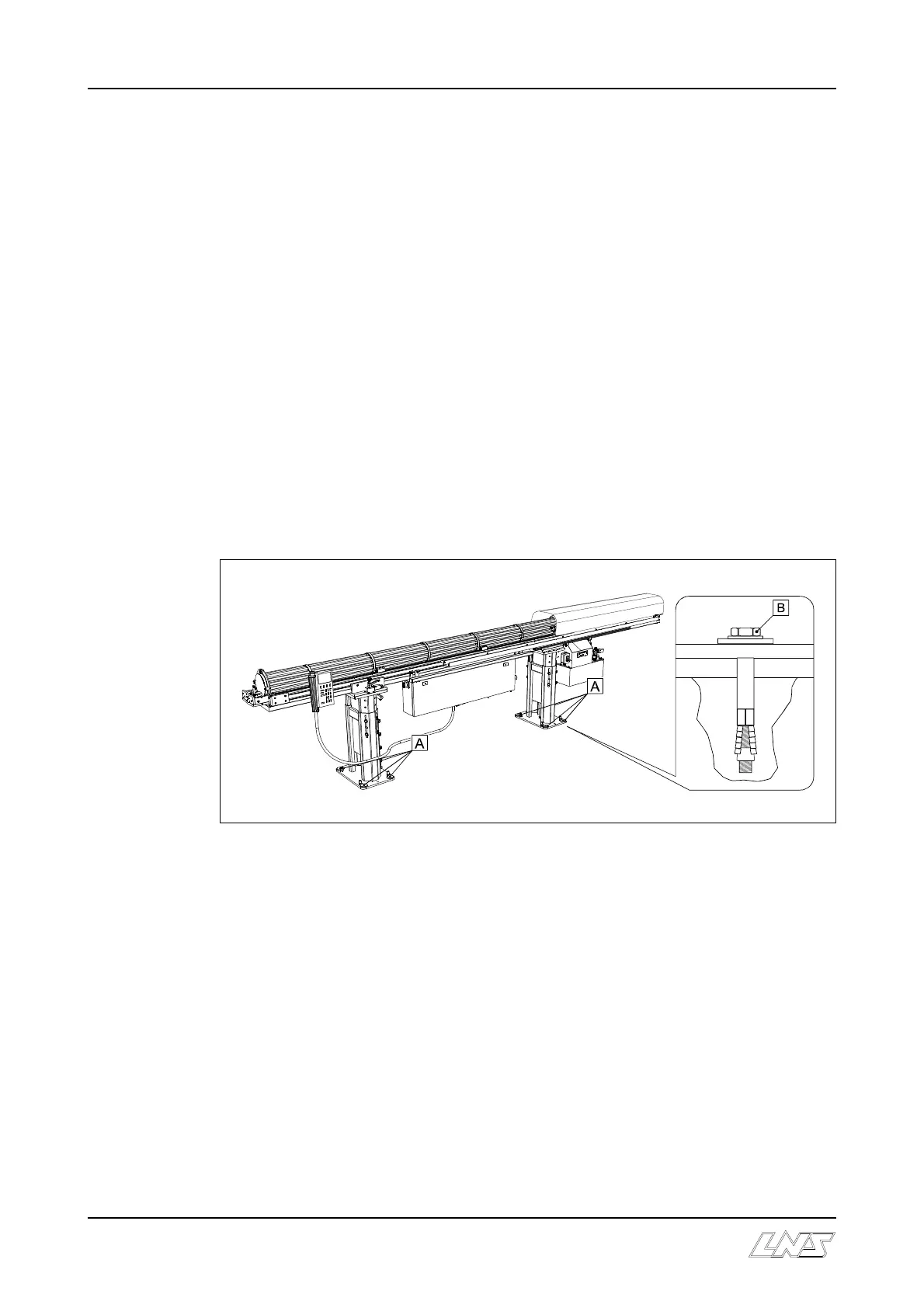

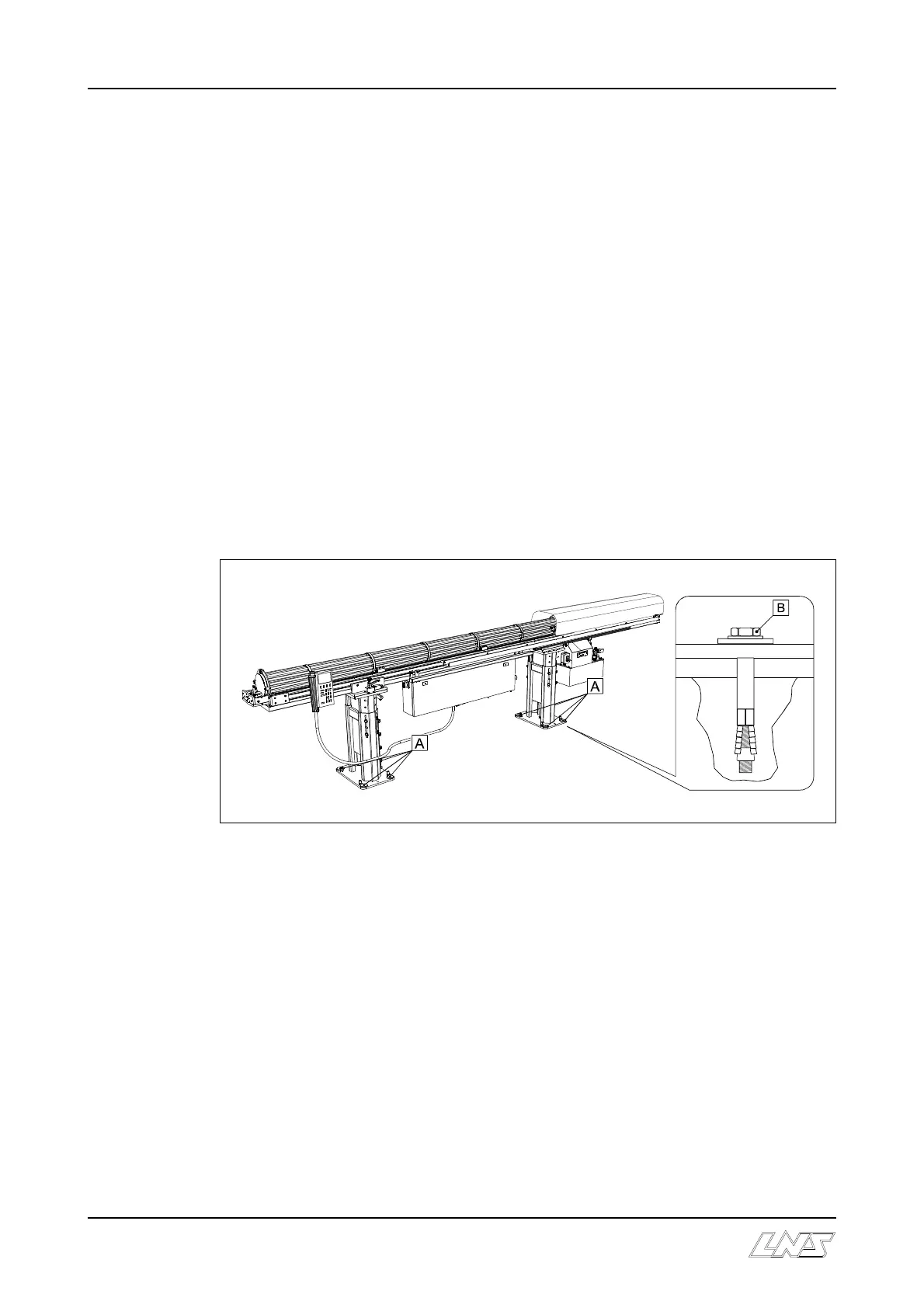

3. ANCHORING TO THE GROUND

Once the bar feed system is in place, and perfectly aligned, it should be anchored to the

ground to make it stable. To accomplish this, 8 anchorage points (A) have been provided

8 anchorage bolts (B) must be furnished by the client (Minimum M 10 x 100 mm)(Minimum

1/2" x 4")

• Once the anchoring bolts are tightened, check the alignment again, and correct it if

necessary

• Tighten the nuts of the leveling screws.

• Remove the red safety screws of the swing out device (option).

4. CONNECTING

Once the bar feed system has been aligned and anchored to the ground, the bar feeder must

be connected to the interface of the lathe and compressed air needs to be connected. At this

stage, the hydraulic tank may be filled.

• For the electrical connection, please see Chapter 4, Electrics.

• For the pneumatic connection, please see Chapter 5, Pneumatics.

• For filling the tank, please refer to Chapter 6 / Hydraulics.

Loading...

Loading...