3 - 4 CHAPTER 3: SETTING INTO OPERATION

TRYTON 112 CNC

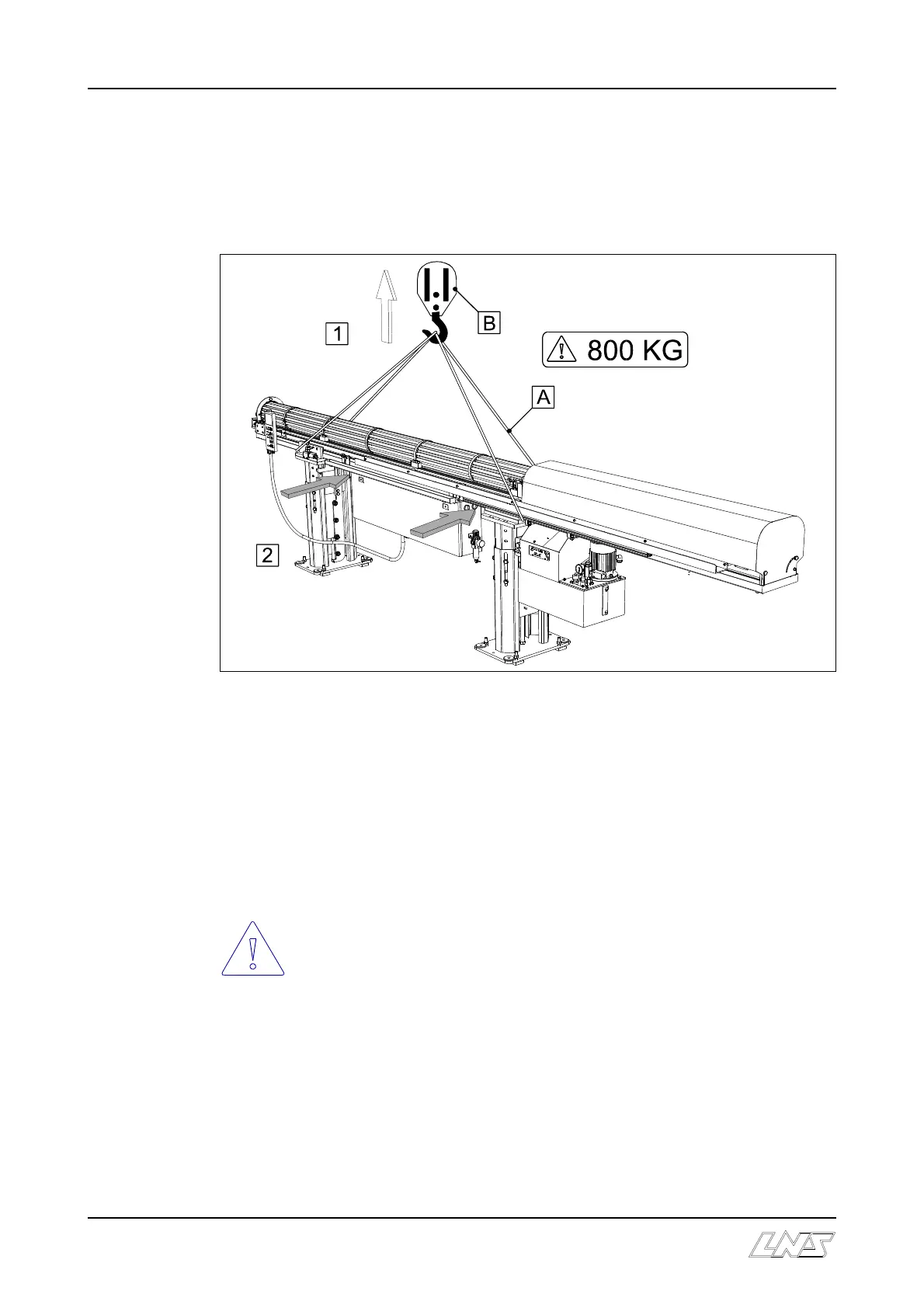

1.3.1 Raising with a hoist

C Position the pulley-block (B) midway between the legs.

C Pass the straps (A) around outside the legs and attach to the block (B).

C Raise the hoist to tighten the straps.

C Remove the screws holding the bar feed system to the pallet during transportation (see

previous page).

C Lift the bar feed system (1) and remove the pallet.

C Move the bar feed system, taking care that it remains horizontal and that no one is nearby

or under the suspended load.

Do not knock the bar feed system as you move it; this may damage it.

C Place the bar feed system behind the lathe, as close as possible and in approximate

alignment with the spindle. For the placement, the stationary and mobile space

requirements for the lathe and the bar feed system should be taken into account.

C When placing the bar feed system insert leveling plates under the feet.

The distance between the lathe and the bar feed system should not exceed 20

mm. Should an obstacle impose a greater distance, contact LNS or their local

representative.

Important : The area around the lathe and the bar feed system must be cleared to allow

for their maintenance and handling. It should remain clear after the

installation is completed.

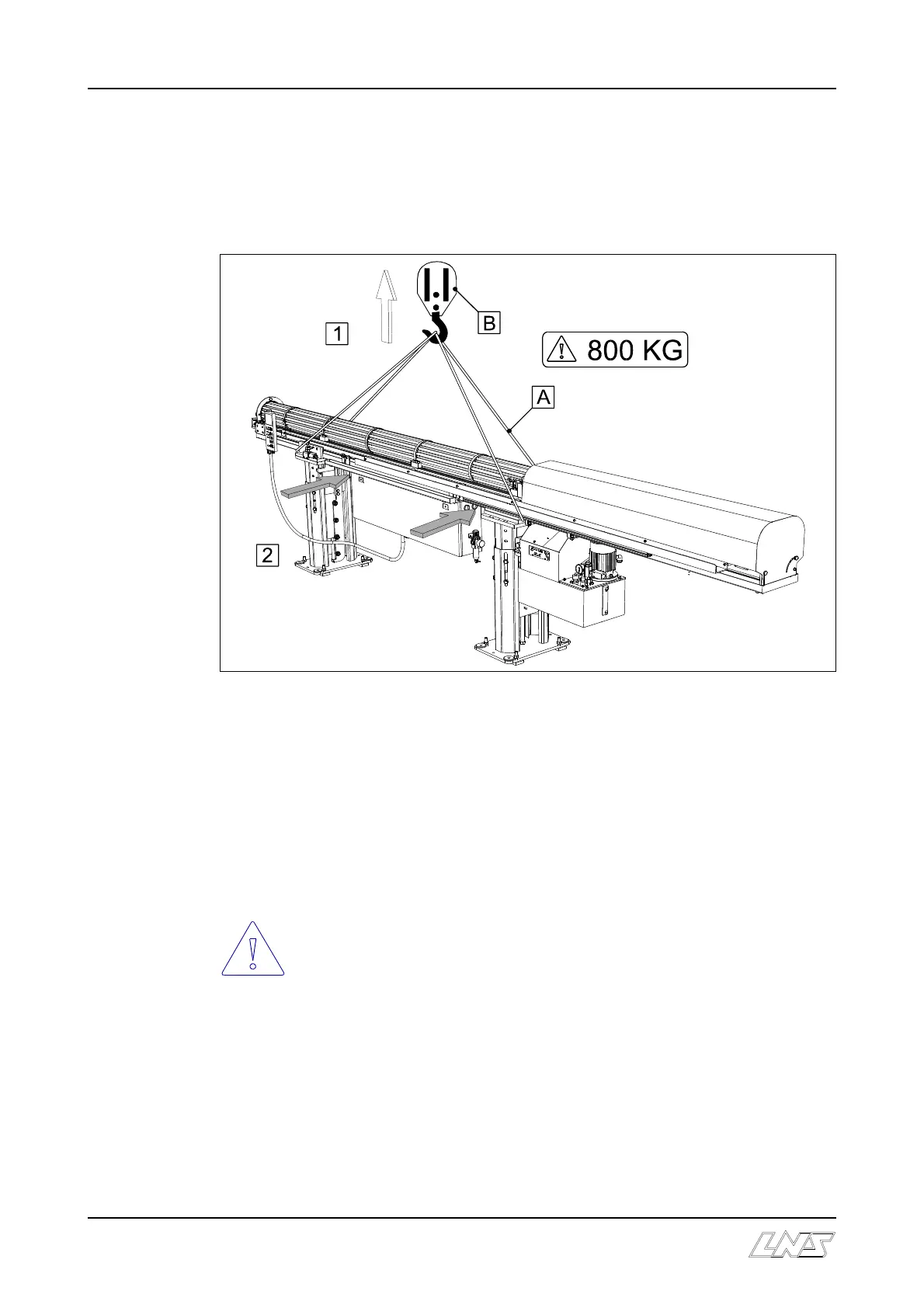

1.3.2 Raising with a fork-lift truck

Separate the lifting arms of the fork-lift truck in order to be able to pass them between the

legs and the electric box (2).

Loading...

Loading...