214327 174 Revision B

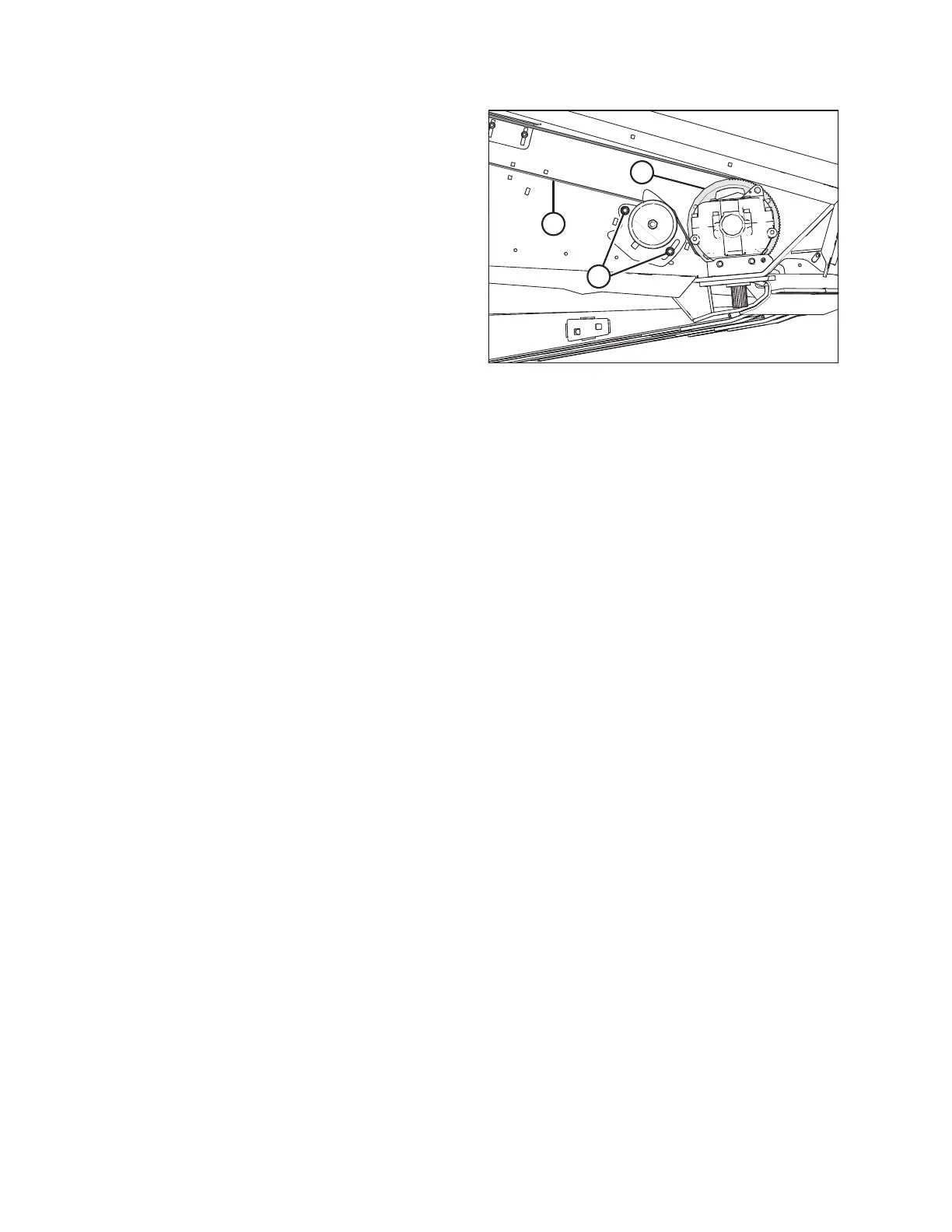

Figure 5.98: Right Knife Drive

9. When the belt has the proper belt tension, tighten nuts (C)

to 73 –80 Nm (54–59 lbf·ft).

10. Ensure the timing belts are properly seated in the grooves

on both driver and driven pulleys.

11. Rotate the drive slowly by hand and observe where the

knives overlap at the center of the header to check for the

correct knife timing.

IMPORTANT:

The knives must begin moving at the exact same time and

must move in opposite directions.

12. Adjust the knife timing, if necessary, by loosening the right

drive belt (B) just enough to reposition it to the next cog(s)

and proceed as follows:

a. If the right knife leads the left knife, rotate the right

driven pulley (A) clockwise.

b. If the right knife lags the left knife, rotate the right

driven pulley (A) counterclockwise.

13. Ensure the drive pulleys don’t rotate, and tension the right drive belts (refer to Step 7, page 173 to Step 9, page 174).

IMPORTANT:

Do NOT use the adjuster bolt at the drive pulley to adjust the timing belt tension.

14. Recheck the timing (refer to Step 11, page 174) and readjust it if necessary (refer to Step 12, page 174).

15. Close both endshields. For instructions, refer to Closing Endshield, page 36 .

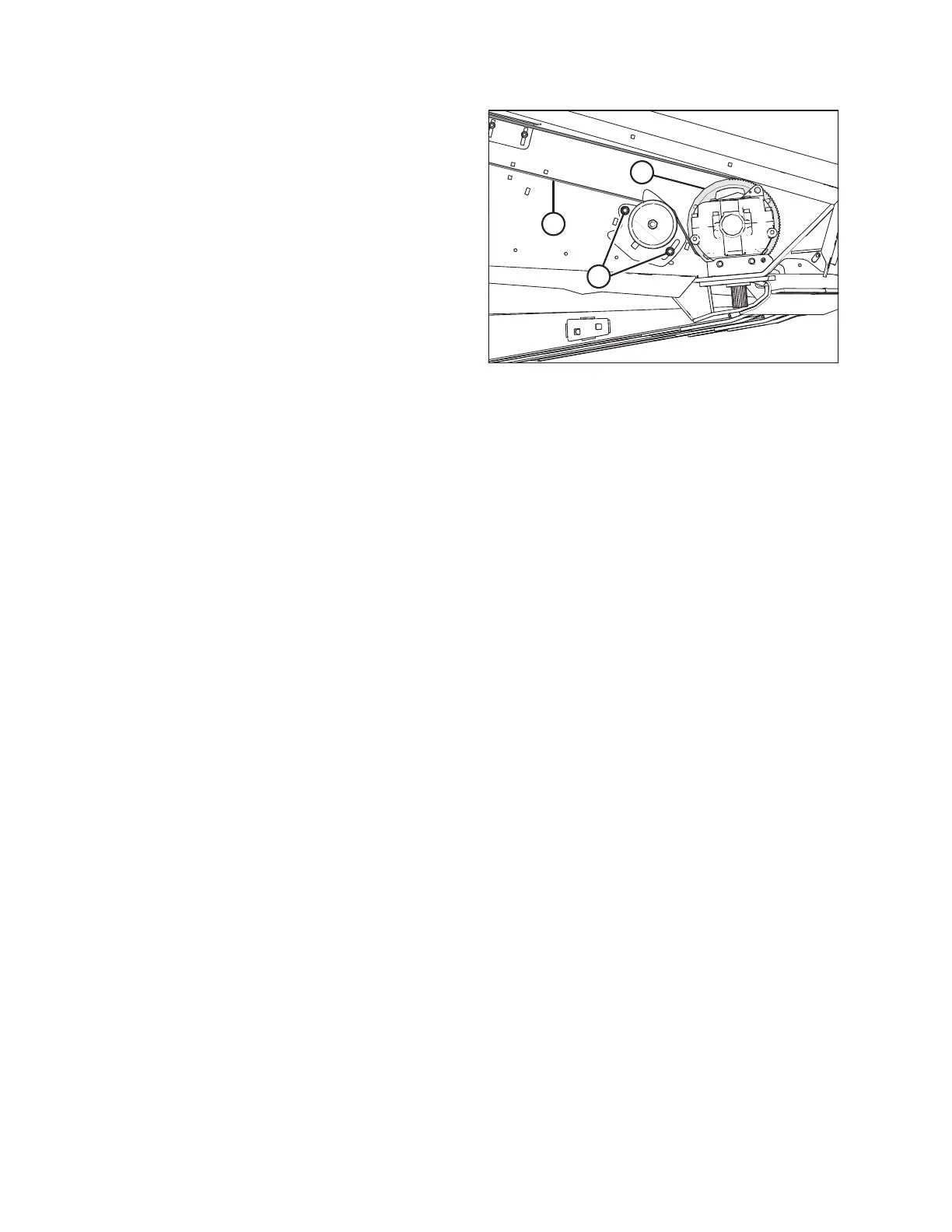

Checking Knife Drive Belt Tracking

The following procedure is applicable to the left knife drive and the right knife drive on timed drive headers.

IMPORTANT:

A belt that is not tracking properly is subject to premature failure. Ensure the pulleys are aligned and parallel. Follow the

belt tensioning procedures in this manual to avoid misalignment.

The cogged timing belt should be centered on the knife drive box pulley and at least 2 mm (0.08 in.) from either edge when

the header is running. The belt should avoid continual contact with the drive pulley flanges. Occasional contact is

acceptable. A gap should be visible between the belt and the pulley flanges.

MAINTENANCE AND SERVICING

Loading...

Loading...