M A E D A Crawler Crane 6.5 USE OF FUEL AND LUBRICATING OIL

5/2020 CC1908S-1 6-11

USE OF FUEL AND LUBRICATING OIL DEPENDING ON

TEMPERATURE

Select as follows to suit the ambient air temperature:

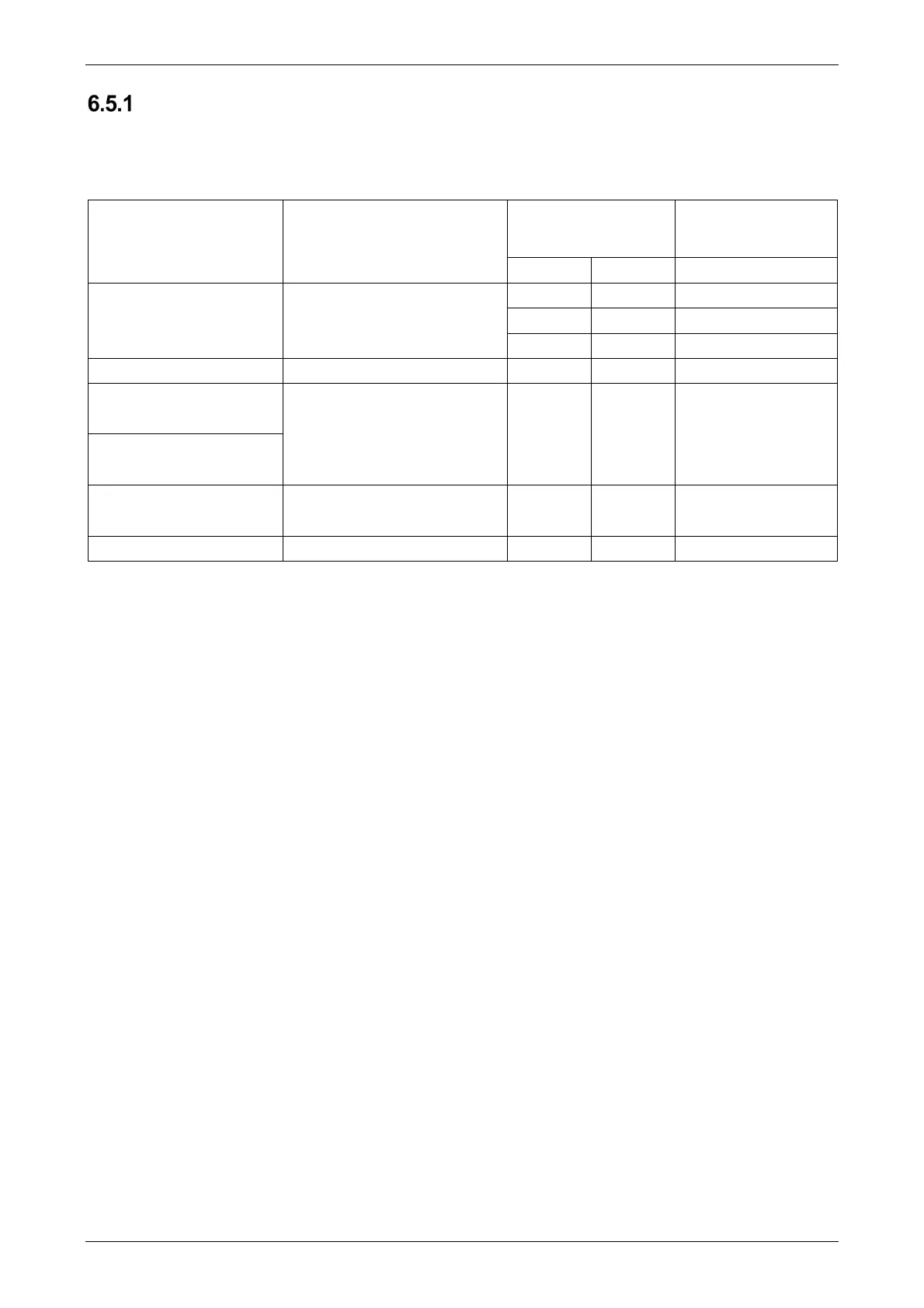

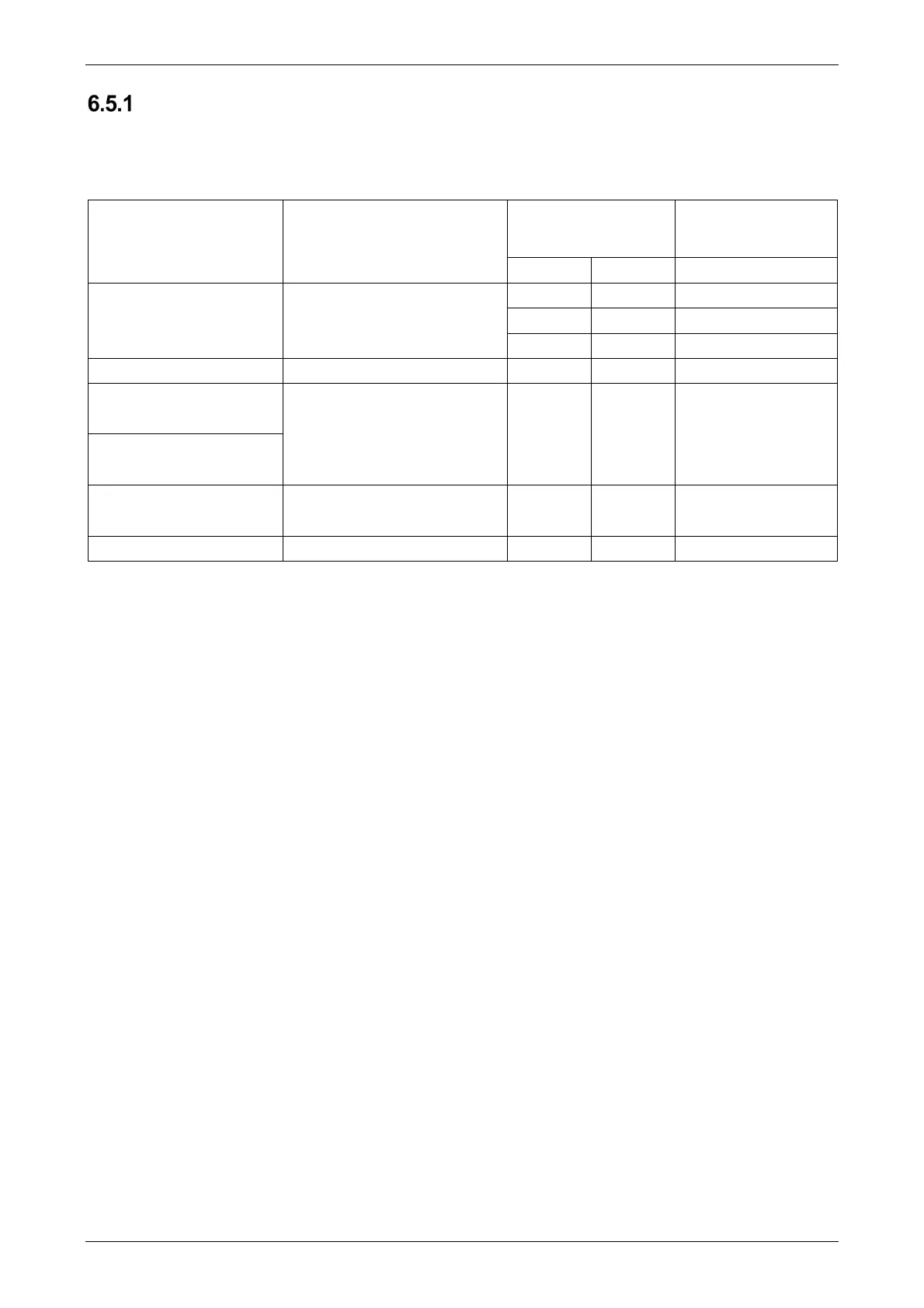

Lubricating oil chart

Lubrication area Oil type

Usage

temperature range

(°C)

Recommended oil

Minimum Maximum

Engine oil pan Engine oil (See Note 1.)

-25 30 SAE 5W-30

-20 30 SAE 10W-30

-15 40 SAE 10W-40

Hydraulic oil system Power line oil -20 40

SAE 10W

Winch motor gearbox

casing

Gear oil -20 40 SAE 90 GL4

Travelling motor gearbox

casing

Cooling system

Coolant (See Note 2.)

Dilution water

-30 40

LLC

ELC

Fuel tank Diesel fuel - - (See Note 3.)

Note 1: Engine oil

(1) Use engine oil equivalent to or better than the following standards and types.

• API service type CJ-4 or CK-4

• ACEA service type E-6

• JASO service type DH-2

(2) The machine is provided with SAE 10W-40 DH-2 oil when shipped from the factory.

(3) When replacing the oil with oil of a different grade, be sure to replace all of the oil and not mix different types.

Note 2: Coolant

(1) Coolant plays an important function in preventing corrosion in the cooling system, as well as in protecting

against freezing.

This coolant must therefore always be used even in areas where anti-freeze is not required.

Use of coolants other than long-life coolant (LLC) or extended-life coolant (ELC) is not recommended in

normal circumstances. Otherwise, there is a risk of serious failure in the cooling system, including the

engine.

(2) For details on coolant dilution ratio, refer to [1] Cooling water replacement in "6.17.9 MAINTENANCE

EVERY 2,000 HOURS" on P.6-70.

Always use soft water for diluting the coolant.

At the time of shipping, unless otherwise indicated, genuine coolant (LLC) is added at a ratio of at least 30 %

or more. There is therefore no need to alter the concentration unless temperatures are below -10 °C.

For temperatures below -10 °C, adjust the coolant concentration using the mixture chart in [1] Cooling water

replacement in "6.17.9 MAINTENANCE EVERY 2,000 HOURS" on P.6-70.

(3) To maintain the anti-corrosion performance of the coolant, always keep the concentration at 30 % to 60 % or

higher.

(4) Use coolant equivalent to or better than the following standards.

• ASTM D6210 or D4985

• JIS K-2234

• SAE J814C, J1941, J1034, or J2036

Loading...

Loading...