M A E D A Crawler Crane 6.17 PERIODIC MAINTENANCE

5/2020 CC1908S-1 6-55

[2] Winch gearbox casing oil level

inspection/refilling

WARNING

• Parts will still be hot immediately after

stopping the engine operation. Do not check

the oil level immediately. Wait until the oil

has cooled.

• The oil and plug may fly out if there is

residual pressure inside the case. Slowly

loosen the plug to relieve the pressure.

IMPORTANT

• For details on the oil used, refer to "6.5.1

USE OF FUEL AND LUBRICATING OIL

DEPENDING ON TEMPERATURE" on P.

6-11.

• Inspect the O-ring condition after inspecting

and refilling the oil, then securely tighten the

plug.

• Prepare a hexagonal wrench.

1.

Stop the machine on firm, level ground, and

lower the boom to its lowest position.

2.

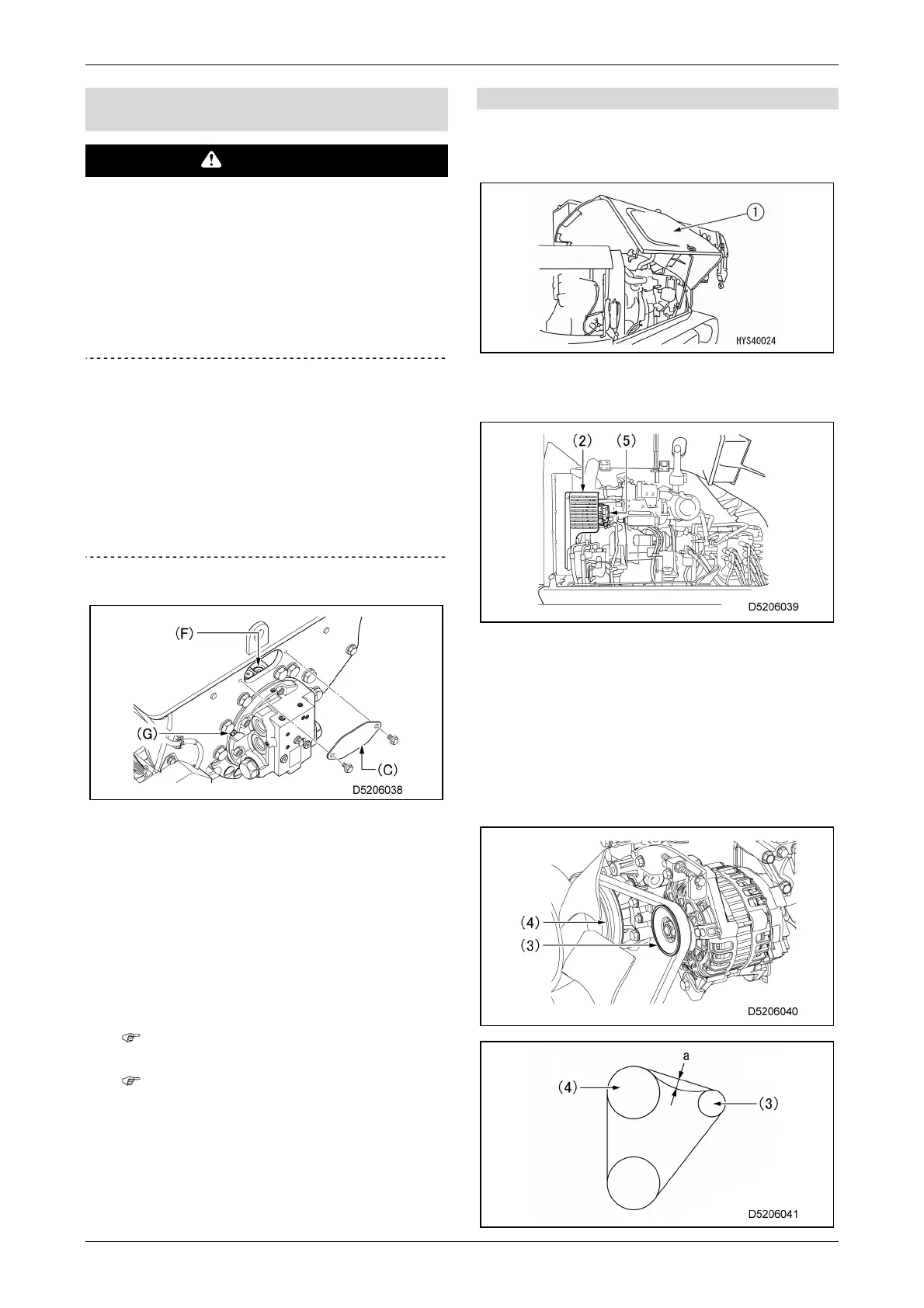

Remove the cover (C).

3.

Using a hexagonal wrench, remove the oil

level check plug (G) and check that oil

overflows from the plug hole.

4.

If the oil level is low, remove the oil inlet plug

(F) and replenish oil via the plug hole.

Replenish the oil until it overflows from

the oil level check plug (G) hole.

Wipe clean any spilt oil.

5.

After checking and refilling oil, reattach the oil

inlet plug (F) and oil level check plug (G) and

securely tighten them.

6.

Attach the cover (C).

[3] Fan belt tension inspection/adjustment

[Tension check]

1.

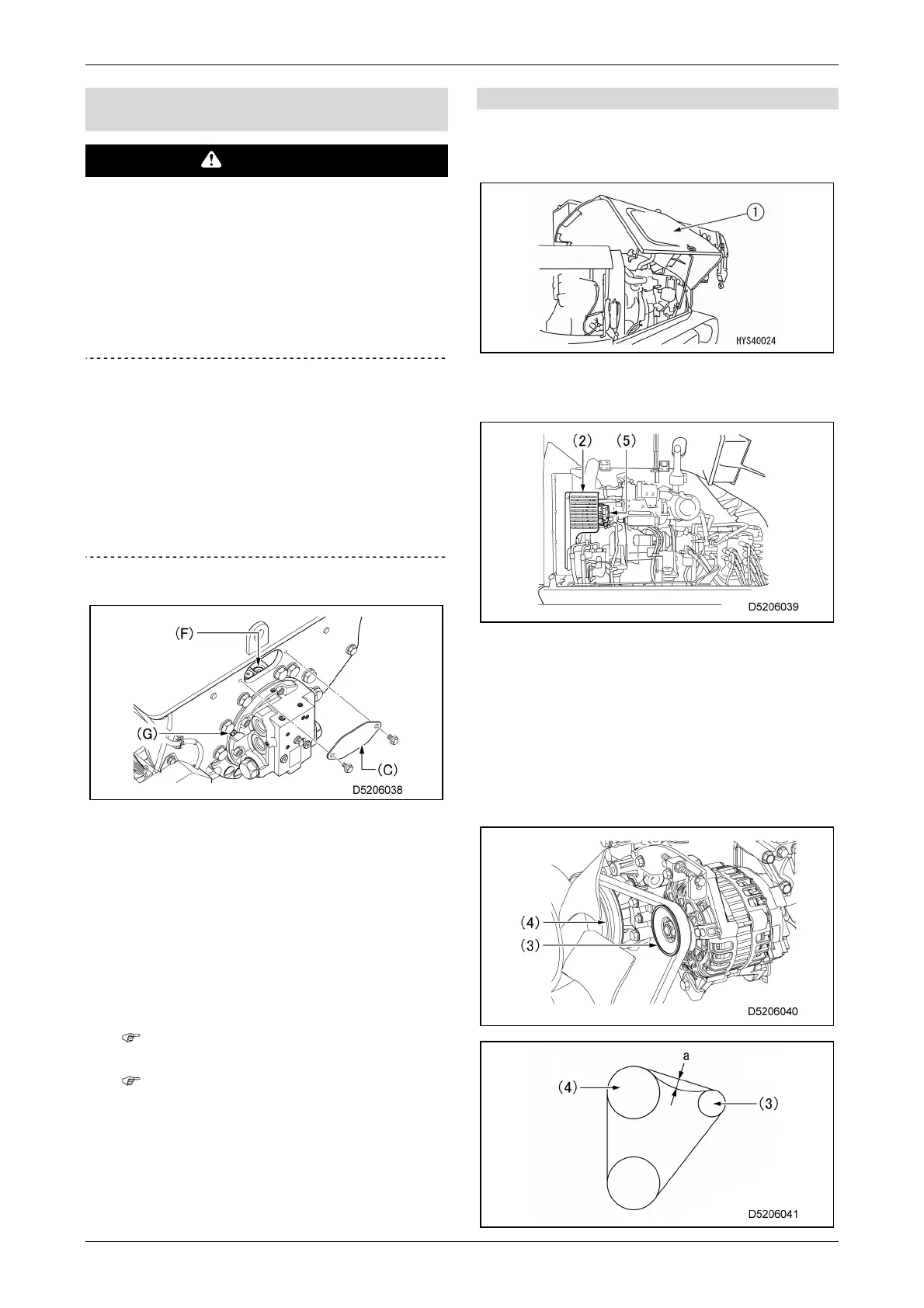

Open the machinery cover (1).

2.

Remove the fan guard (2) covering the

alternator (5).

3.

Press down on the middle of the belt between

the alternator pulley (3) and fan pulley (4) with

your thumb (approximately 98 Nꞏm [10

kgfꞏm]) to ensure that the deflection (a) is

within the prescribed range of 7 mm to 10

mm.

• If measuring using a sonic tensiometer, it

is normal if the value is within the range

101 Hz to 113 Hz.

Loading...

Loading...