6.17 PERIODIC MAINTENANCE M A E D A Crawler Crane

6-56 5/2020 CC1908S-1

IMPORTANT

When checking the fan belt tension, check

the following at the same time:

• Check the pulleys for damage, V groove

wear, and V belt wear. In particular, make

sure that the belt is not in contact with the

bottom of the V groove.

• If the belt has stretched leaving no margin

for adjustment, or if it is cut or cracked and

makes a slipping/squeaking sound, contact

us or our sales service agency for

replacement.

4. If tension adjustment is necessary, proceed

to Step 5 of [Tension adjustment]. If the

tension is satisfactory, proceed to Step 9.

[Tension adjustment]

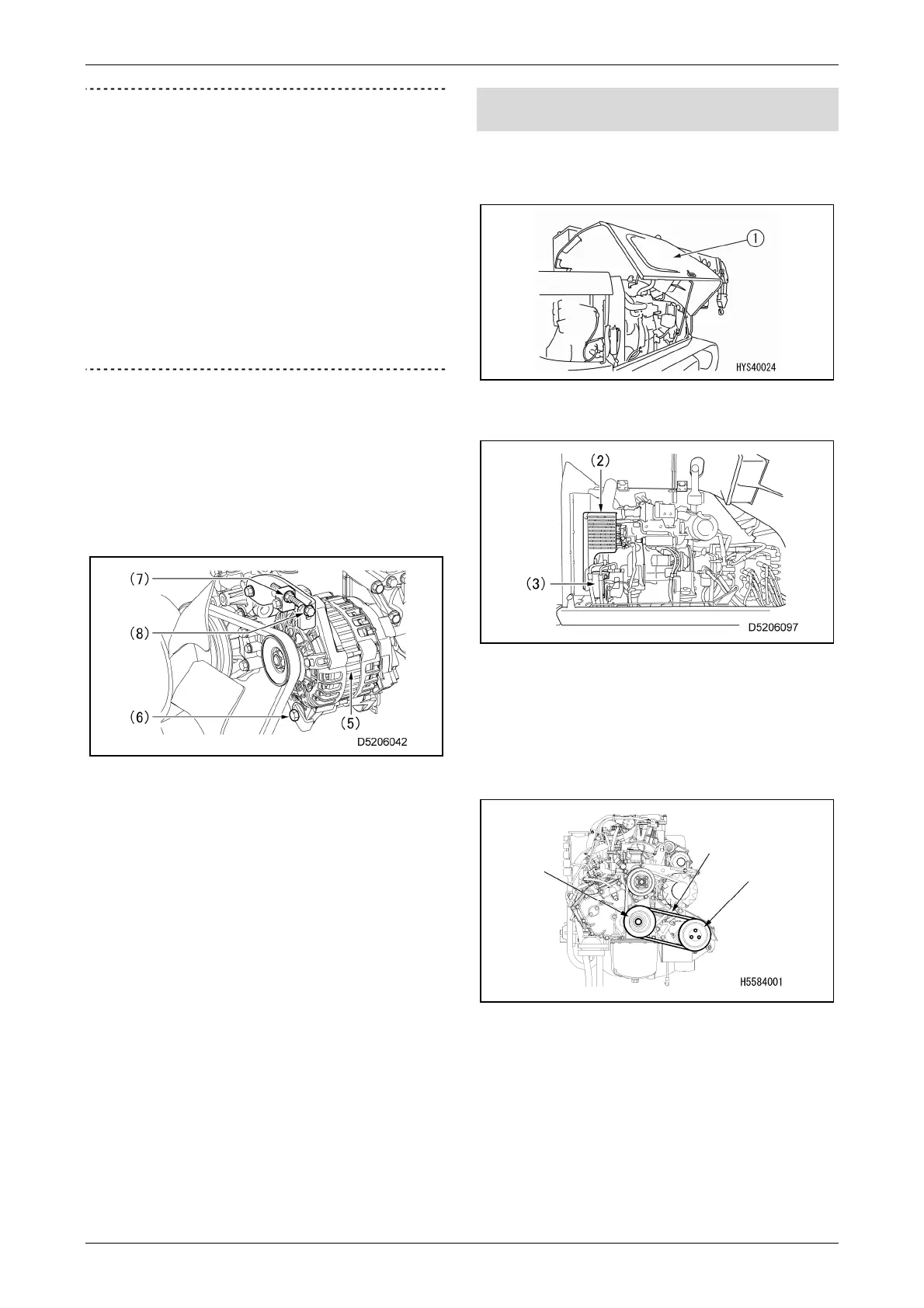

5. Loosen the mounting bolts (6) on the

alternator (5).

6. Loosen the alternator lock nut (7).

7. Turn the adjuster bolt (8) on the alternator (5)

in the loosening direction to adjust the belt

tension so that it gives a deflection between 7

mm and 10 mm (approximately 98 Nꞏm [10

kgfꞏm]).

After replacing the belt, run the machine for at

least five minutes before readjusting.

8. Tighten the mounting bolt (6) and lock nut (7).

Tightening torque

・M8 bolt: 23.5 N・m [2.4 kgf・m]

・M10 bolt: 48.0 N・m [4.9 kgf・m]

9. Attach the fan guard (2).

10. Close the machinery cover (1).

[4] A/C compressor belt tension

inspection/adjustment

[Tension check]

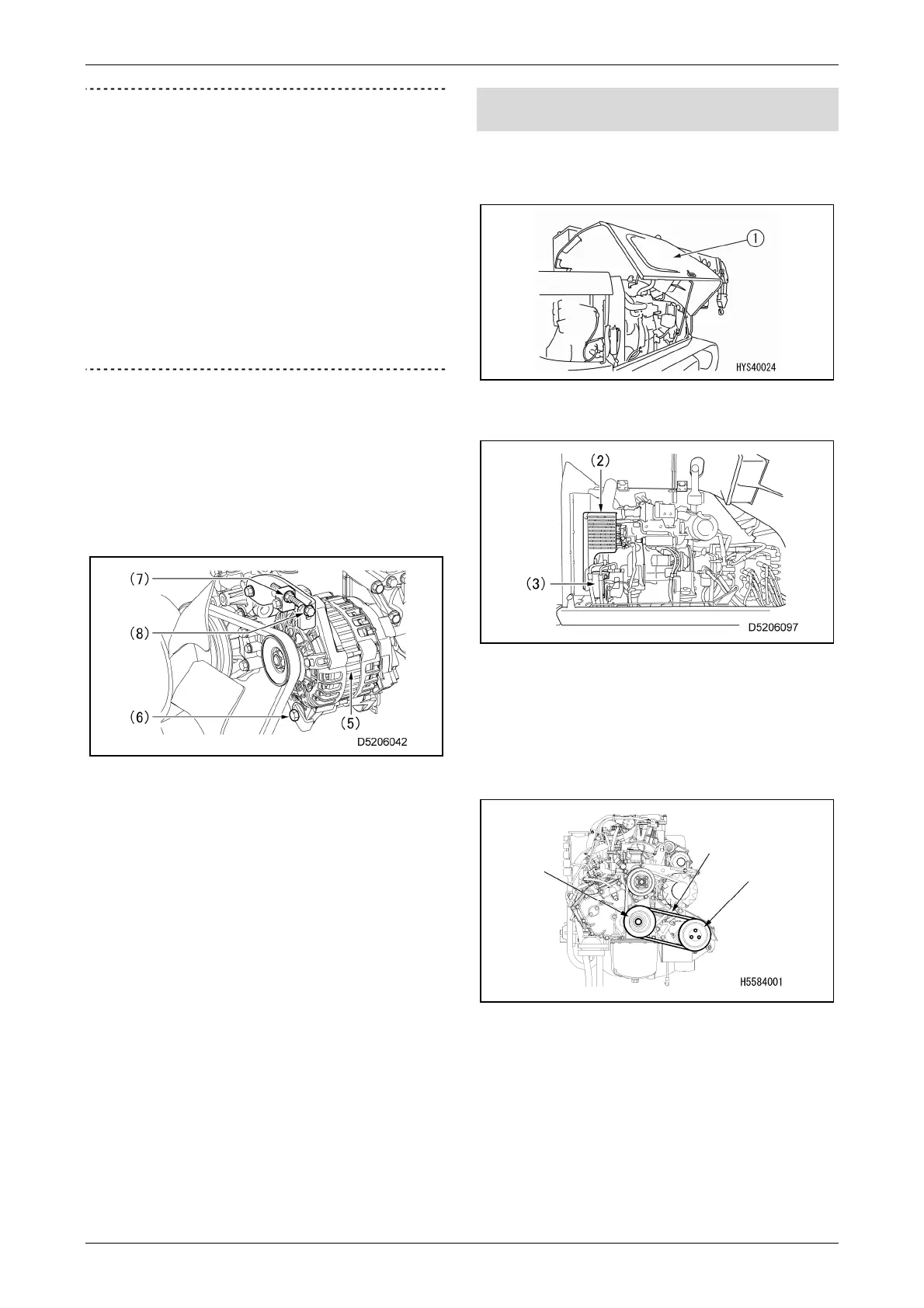

1. Open the machinery cover (1).

2. Remove the fan guard (2) and compressor

guard (3).

3. Press down on the middle of the belt (A)

between the crank pulley (4) and the

compressor pulley (5) with your thumb

(approximately 17.7 N [1.8 kgf]) and confirm

that the deflection is the standard value of 4

mm.

4. If tension adjustment is necessary, proceed

to Step 5 of [Tension adjustment]. If the

tension is satisfactory, proceed to Step 9

(4)

(5)

(A)

Loading...

Loading...