Section 5 – LUBRICATING OIL

Mini-Crawler Crane M A E D A

5-14 3/2019 MC305C-3

LUBRICATING OIL

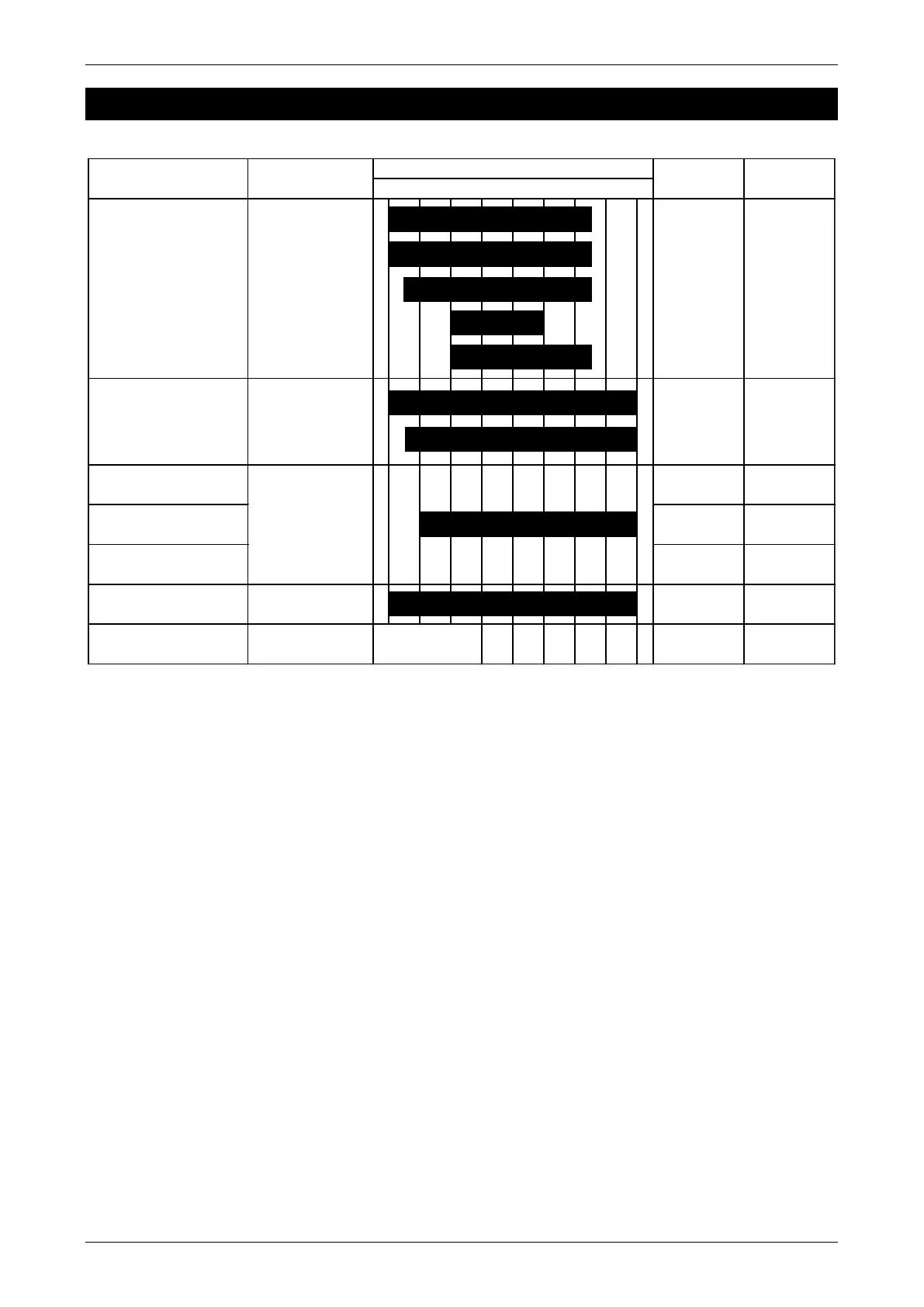

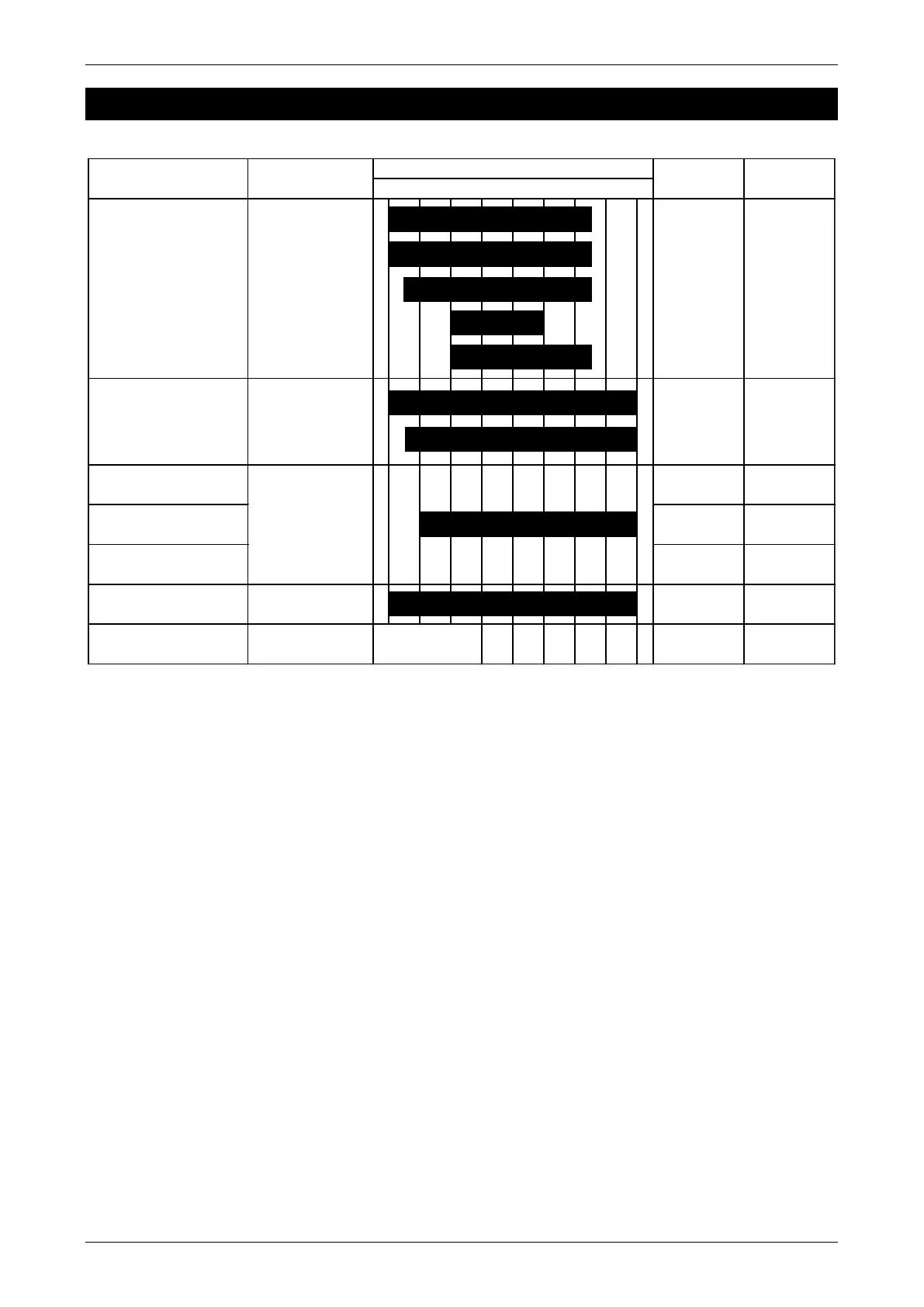

Use of lubricating oil should vary with changes in temperature.

Wear resistant

hydraulic oil

60 44

Slewing reducer 0.6 0.6

Winch reducer 0.75 0.75

Travel motor reducer

0.7 0.7

Fuel tank

Nonfreezing fluid addition

-22 -4 14 32 50 68 86 104 122 ºF

Fig. 5-20

• A specified oil quantity is defined as a total

quantity of oil including that for unit piping, and a

replacement oil quantity is defined as a quantity

of oil to be replaced at inspection and

maintenance.

• Be sure to use our recommended

abrasion-resistant hydraulic oil for the hydraulic

oil system; ISO VG46 and VG32.

"Nippon Oil Super Highland 32" is adopted for a

hydraulic oil system as factory default.

• For adjustment of antifreeze concentrations in

coolant with temperature at -10°C or below, see

"Coolant Replacement and Internal Cleaning"

on page 5-49.

CAUTION:

• Molybdenum disulfide filled grease is to be

applied to the boom slide plate (top), both

sides and bottom of the boom.

• Do not apply molybdenum disulfide filled

grease to the slewing bearing.

Loading...

Loading...