Section 5 – TROUBLESHOOTING Mini-Crawler Crane M A E D A

5-88 3/2019 MC305C-3

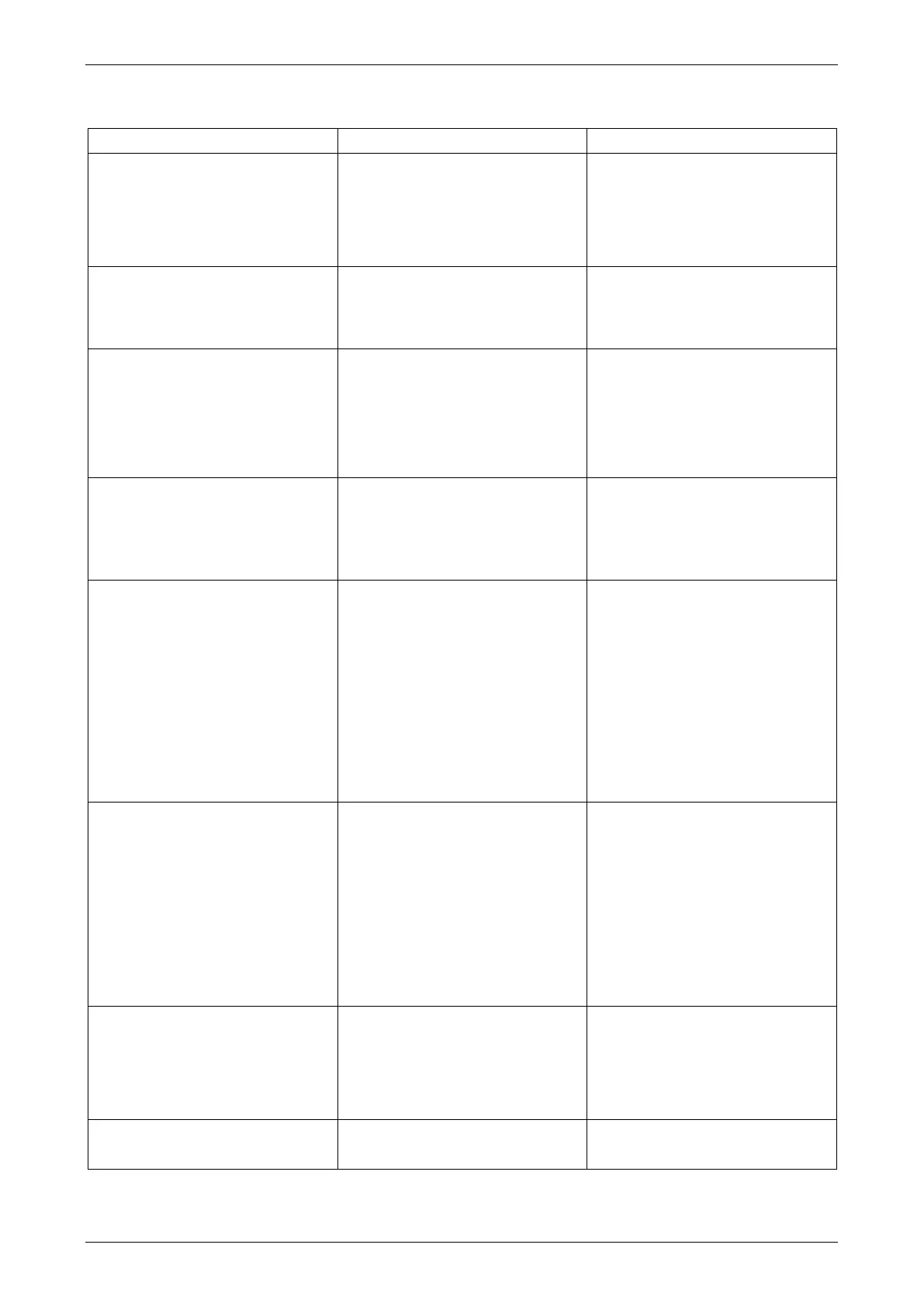

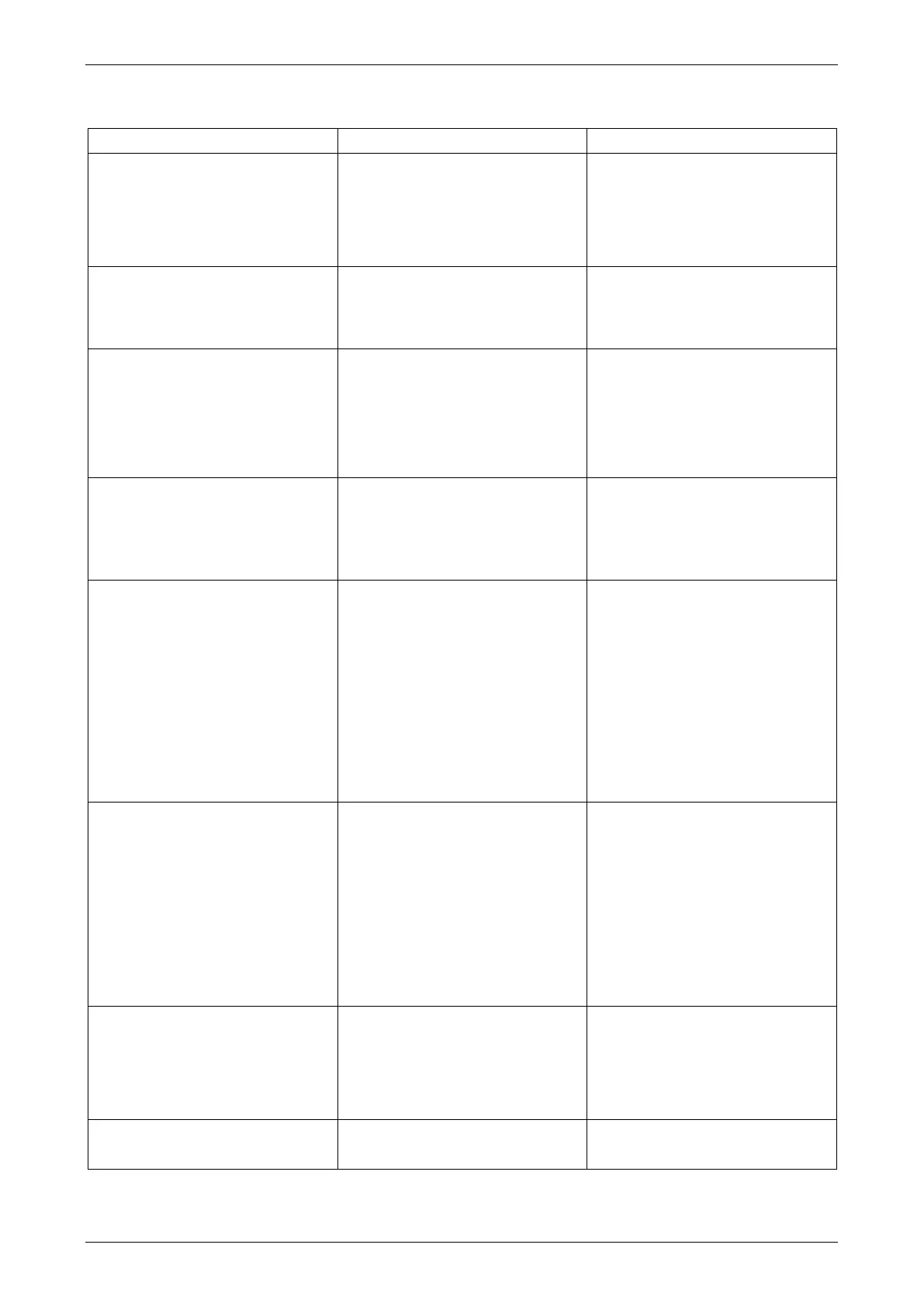

Electric Motor

The motor remains off despite the

switch being turned to the

"START" position.

• Improper wiring and power

supply error

• The Inverter unit breakers: OFF

• A break in stator winding

• Check wiring, see "ELECTRIC

MOTOR OPERATION" on page

4-122.

• Turn ON the breakers.

(• Inspection, repair, replacement)

(• Inspection, repair, replacement)

The motor comes to a stop during

use.

• Inverter unit error

(Red lamp: ON)

• Failure in the Inverter unit

• Failure in the power unit

• Check the power supply source

(voltage and phase interruption).

(• Inspection, repair, replacement)

(• Inspection, repair, replacement)

The power output of the motor

reaches zero or undergoes

gradual decrease.

• Phase interruption in the power

source of power supply

equipment

• Slack in motor wiring

• Check the power source of

power supply equipment (voltage

and phase interruption).

• Inspect connection with the

motor Terminal block.

(• Inspection, repair, replacement)

The cabtyre cable rises in

temperature.

• Considerable voltage drop

• Ensure that the power supply

voltage of power supply

equipment is at a specified value.

• Replace the cabtyre cable with

one adhering to specifications.

An abnormal noise and vibration

are present in the power unit

during operation.

• A break in motor winding

• Looseness in the motor and

pump fixing bolt

• Looseness in the coupling fixing

bolt

• Impurities on the coupling

• Clogging in the hydraulic oil tank

strainer and element

• Inspect the motor Terminal

block.

(• Inspection, repair, replacement)

• Perform inspection, repair, and

cleaning. See "ELECTRIC

MOTOR OPERATION" on page

4-122.

(• Replacement)

• Clean and replace the strainer

and element according to

periodic inspection.

The power unit rises in

temperature during operation.

• High ambient temperature

• Ill-ventilated

• Considerable voltage drop

• Overload

• High number of starts

• Use the power unit in

environment compliant with

specifications.

• Perform inspection and

cleaning, See "ELECTRIC

MOTOR OPERATION" on page

4-122.

• Replace the cabtyre cable with

one adhering to specifications.

• Reduce loads.

• Reduce the number of starts.

The leak detector of the Inverter

unit main breaker is tripped.

• High humidity

• Presence of water droplets

• Ill-grounded

• A break in stator winding

• Use the leak detector in

environment compliant with

specifications.

• Attach the cover properly.

• Adhere to ground standards.

(• Inspection, repair, replacement)

The trouble lamp (red) of the

Inverter unit comes on.

• Failure in the Inverter unit

(• Inspection, repair, replacement)

Loading...

Loading...